Features:

1. Long travel ranges (100 to 1200 mm) with profile (230 mm width)

2. Highly dynamic, maintenance-free linear motor with velocities up to 5 m/s

3. Robust industrial design for a long lifetime

4. High-precision famous brand grating

5. Maximum peak thrust to 1650 N

6. Ideal for gantry systems

Brand:

HAN'S MOTOROrder(MOQ):

1Product name:High-Speed Full Protect Linear Stage For Cleanroom Environment

Full protect design for applications with cleanroom or anti-dust environment requirements

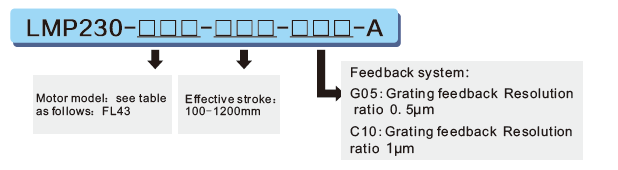

The LMP230 is a heavy-duty and highly dynamic linear stage for industrial applications. Its design is consistently geared to demanding industrial conditions and it is characterized by high stiffness and the use of high-quality components: THK guides, iron core linear motor, Renishaw grating. The high resolution of grating allows an excellent tracking performance, small tracking errors, and short settling times.

Linear motor with iron core

3-phase magnetic direct drives do not use mechanical components in the drivetrain, they transmit the drive force to the motion platform directly and without friction. The drives reach high velocities and accelerations. Iron core motors are particularly suitable for high thrust and high rigidity tasks. Ironless motors are particularly suitable for positioning tasks with the highest demands on precision because there is no undesirable interaction with the permanent magnets. This allows smooth running even at the lowest velocities and at the same time, there is no vibration at high velocities. Nonlinearity in control behavior is avoided and any position can be controlled easily. The drive force can be set freely.

Application fields

Laser cutting, automation, biotechnology, sample manipulation, sample positioning, applications with severe environment and so on.

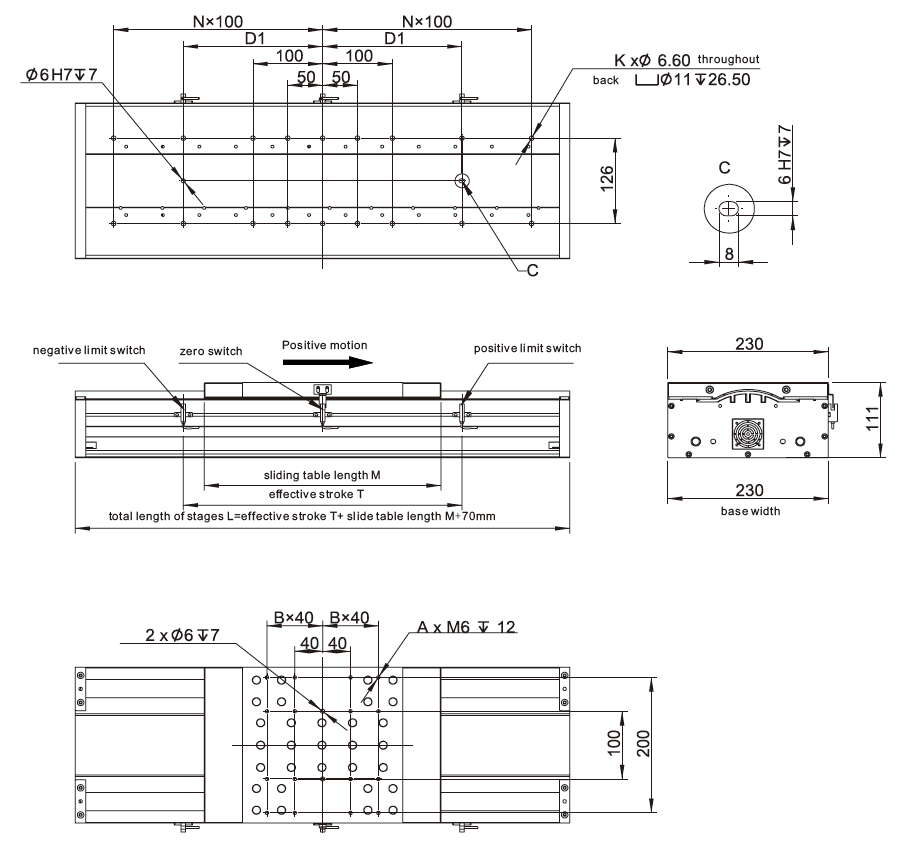

Dimensions

Motor Model And Specifications

|

|

ironless motor |

||||

| Parameter\Motor Model | Units | U53 | U54 | U55 | U56 |

|

Continuous Force (Tmax) |

N | 168 | 224 | 280 | 336 |

|

Peak Force |

N | 936 | 1248 | 1560 | 1872 |

|

Motor Constant |

N//SqrtW |

15 | 17.4 | 19.4 | 21.3 |

|

Max.Continuous Power Dissipation |

W |

125 | 166.6 | 208.3 | 250 |

|

Continuous Current (Tmax) |

Arms |

2.3 | 2.3 | 2.3 | 2.3 |

|

Peak Current (1S) |

Arms |

13 | 13 | 13 | 13 |

|

Force Constant (25℃,±5%) |

N/Arms |

73 | 96 | 120 | 144 |

|

Back EMF Constant (25℃,±5%) |

Vrms/rad/s |

24.3 | 32 | 40 | 48 |

|

Resistance(25℃,±5%)P-P |

Ω |

11.25 | 15 | 18.75 | 22.5 |

|

Inductance(25℃,±20%)P-P |

mH |

10.5 | 14 | 17.5 | 21 |

|

Max Coil Temperature |

℃ |

120 | 120 | 120 | 120 |

|

Polar Distance (N-N) |

mm |

60 | 60 | 60 | 60 |

|

Magnetic Attraction |

KN |

0 | 0 | 0 | 0 |

|

Mover Mass |

Kg | 1 | 1.3 | 1.65 | 2 |

|

|

motor with iron core |

||||||||

| Parameter\Motor Model | Units | FJ22 | FJ23 | FL22 | FL32 | FL42 | FL23 | FL33 | FL43 |

|

Continuous Force (Tmax) |

N | 208 | 332 | 196 | 294 | 392 | 314 | 472 | 629 |

|

Peak Force |

N | 831 | 1329 | 517 | 776 | 1035 | 827 | 1237 | 1653 |

|

Motor Constant |

N//SqrtW |

27.5 | 24.4 | 18.9 | 23.4 | 27.2 | 25.3 | 31.0 | 36.2 |

|

Max.Continuous Power Dissipation |

W |

57.1 | 184.8 | 107.5 | 157.9 | 208.3 | 154.6 | 231.8 | 302.4 |

|

Continuous Current (Tmax) |

Arms |

2.2 | 4.4 | 4 | 4 | 4 | 4 | 4 | 4 |

|

Peak Current (1S) |

Arms |

9 | 18 | 12 | 12 | 12 | 12 | 12 | 12 |

|

Force Constant (25℃,±5%) |

N/Arms |

94.8 | 75.6 | 49 | 73.5 | 98 | 78.5 | 118 | 157 |

|

Back EMF Constant (25℃,±5%) |

Vrms/rad/s |

31.6 | 25.2 | 16.3 | 24.5 | 32.7 | 26 | 39.3 | 52.4 |

|

Resistance(25℃,±5%)P-P |

Ω |

11.8 | 4.5 | 3.2 | 4.7 | 6.2 | 4.6 | 6.9 | 9 |

|

Inductance(25℃,±20%)P-P |

mH |

40 | 15.3 | 15 | 22.5 | 30 | 24 | 36 | 48 |

|

Max Coil Temperature |

℃ |

120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

|

Polar Distance (N-N) |

mm |

20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

|

Magnetic Attraction |

KN |

1.23 | 1.82 | 1.1 | 1.6 | 2.1 | 1.7 | 2.6 | 3.4 |

|

Mover Mass |

Kg | 1.7 | 2.4 | 2.5 |

3.7 |

4.9 | 3.8 | 5.5 | 7.3 |

LMP230-U53-□□□-□□□-A:

|

Parameter\ Stroke (mm) |

100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 10 | 14 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 |

| N | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 |

|

Stage Total Length (mm) |

420 | 520 | 620 | 720 | 820 | 920 | 1020 | 1120 | 1220 | 1320 | 1420 | 1520 |

|

Dowel Pin D1 (mm) |

50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

|

Stage Weight (kg) |

23 | 27 | 31 | 35 | 39 | 43 | 47 | 51 | 55 | 59 | 63 | 67 |

|

Sliding Table M (mm) |

250 | |||||||||||

| A |

8 |

|||||||||||

| B |

1 |

|||||||||||

|

Motion Parts Weight (kg) |

7 |

|||||||||||

LMP230-U54-□□□-□□□-A:

|

Parameter\ Stroke (mm) |

100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 14 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 | 34 |

| N | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 |

|

Stage Total Length (mm) |

470 | 570 | 670 | 770 | 870 | 970 | 1070 | 1170 | 1270 | 1370 | 1470 | 1570 |

|

Dowel Pin D1 (mm) |

50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

|

Stage Weight (kg) |

26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 | 58 | 62 | 66 | 70 |

|

Sliding Table M (mm) |

300 | |||||||||||

| A |

16 |

|||||||||||

| B |

2 |

|||||||||||

|

Motion Parts Weight (kg) |

8.5 |

|||||||||||

LMP230-U55-□□□-□□□-A:

|

Parameter\ Stroke (mm) |

100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 10 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 | 34 |

| N | 1 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 |

|

Stage Total Length (mm) |

390 | 630 | 730 | 830 | 930 | 1030 | 1130 | 1230 | 1330 | 1430 | 1530 | 1630 |

|

Dowel Pin D1 (mm) |

50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

|

Stage Weight (kg) |

11.5 | 34 | 38 | 42 | 46 | 50 | 54 | 58 | 62 | 66 | 70 | 74 |

|

Sliding Table M (mm) |

360 | |||||||||||

| A |

16 |

|||||||||||

| B |

2 |

|||||||||||

|

Motion Parts Weight (kg) |

10 |

|||||||||||

LMP230-U56-□□□-□□□-A:

|

Parameter\ Stroke (mm) |

100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 | 34 | 38 |

| N | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 |

|

Stage Total Length (mm) |

590 | 690 | 790 | 890 | 990 | 1090 | 1190 | 1290 | 1390 | 1490 | 1590 | 1690 |

|

Dowel Pin D1 (mm) |

50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

|

Stage Weight (kg) |

34 | 38 | 42 | 46 | 50 | 54 | 58 | 62 | 66 | 70 | 74 | 78 |

|

Sliding Table M (mm) |

420 | |||||||||||

| A |

24 |

|||||||||||

| B |

3 |

|||||||||||

|

Motion Parts Weight (kg) |

3.8 | |||||||||||

LMP230-FJ22-□□□-□□□-A:

|

Parameter\ Stroke (mm) |

100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 10 | 14 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 |

| N | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 |

|

Stage Total Length (mm) |

420 | 520 | 620 | 720 | 820 | 920 | 1020 | 1120 | 1220 | 1320 | 1420 | 1520 |

|

Dowel Pin D1 (mm) |

50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

|

Stage Weight (kg) |

22.4 | 25.6 | 28.8 | 32 | 35.2 | 38.4 | 41.6 | 44.8 | 48 | 51.2 | 54.4 | 57.6 |

|

Sliding Table M (mm) |

280 | |||||||||||

| A |

8 |

|||||||||||

| B |

1 |

|||||||||||

|

Motion Parts Weight (kg) |

9 | |||||||||||

LMP230-FJ23-□□□-□□□-A:

|

Parameter\ Stroke (mm) |

100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 14 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 | 34 |

| N | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 |

|

Stage Total Length (mm) |

450 | 550 | 650 | 750 | 850 | 950 | 1050 | 1150 | 1250 | 1350 | 1450 | 1550 |

|

Dowel Pin D1 (mm) |

50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

|

Stage Weight (kg) |

24.6 | 27.8 | 31 | 34.2 | 37.4 | 40.6 | 43.8 | 47 | 50.2 | 53.4 | 56.6 | 59.8 |

|

Sliding Table M (mm) |

280 | |||||||||||

| A |

8 |

|||||||||||

| B |

1 |

|||||||||||

|

Motion Parts Weight (kg) |

10.4 | |||||||||||

LMP230-FL22-□□□-□□□-A:

|

Parameter\ Stroke (mm) |

100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 14 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 | 34 |

| N | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 |

|

Stage Total Length (mm) |

510 | 610 | 710 | 810 | 910 | 1010 | 1110 | 1210 | 1310 | 1410 | 1510 | 1610 |

|

Dowel Pin D1 (mm) |

50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

|

Stage Weight (kg) |

29.1 | 32.3 | 35.5 | 38.7 | 41.9 | 45.1 | 48.3 | 51.5 | 54.7 | 57.9 | 61.1 | 64.3 |

|

Sliding Table M (mm) |

340 | |||||||||||

| A |

16 |

|||||||||||

| B |

2 |

|||||||||||

|

Motion Parts Weight (kg) |

13.2 |

|||||||||||

LMP230-FL32-□□□-□□□-A:

|

Parameter\ Stroke (mm) |

100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 10 | 14 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 |

| N | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 |

|

Stage Total Length (mm) |

420 | 520 | 620 | 720 | 820 | 920 | 1020 | 1120 | 1220 | 1320 | 1420 | 1520 |

|

Dowel Pin D1 (mm) |

50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

|

Stage Weight (kg) |

22 | 25 | 28 | 31 | 34 | 37 | 40 | 43 | 46 | 49 | 52 | 55 |

|

Sliding Table M (mm) |

250 | |||||||||||

| A |

8 |

|||||||||||

| B |

1 |

|||||||||||

|

Motion Parts Weight (kg) |

9 | |||||||||||

LMP230-FL42-□□□-□□□-A:

|

Parameter\ Stroke (mm) |

100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 10 | 14 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 |

| N | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 |

|

Stage Total Length (mm) |

420 | 520 | 620 | 720 | 820 | 920 | 1020 | 1120 | 1220 | 1320 | 1420 | 1520 |

|

Dowel Pin D1 (mm) |

50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

|

Stage Weight (kg) |

22 | 25 | 28 | 31 | 34 | 37 | 40 | 43 | 46 | 49 | 52 | 55 |

|

Sliding Table M (mm) |

250 | |||||||||||

| A |

8 |

|||||||||||

| B |

1 |

|||||||||||

|

Motion Parts Weight (kg) |

9 |

|||||||||||

LMP230-FL23-□□□-□□□-A:

|

Parameter\ Stroke (mm) |

100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 10 | 14 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 |

| N | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 |

|

Stage Total Length (mm) |

420 | 520 | 620 | 720 | 820 | 920 | 1020 | 1120 | 1220 | 1320 | 1420 | 1520 |

|

Dowel Pin D1 (mm) |

50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

|

Stage Weight (kg) |

22 | 25 | 28 | 31 | 34 | 37 | 40 | 43 | 46 | 49 | 52 | 55 |

|

Sliding Table M (mm) |

250 | |||||||||||

| A |

8 |

|||||||||||

| B |

1 |

|||||||||||

|

Motion Parts Weight (kg) |

9 |

|||||||||||

LMP230-FL33-□□□-□□□-A:

|

Parameter\ Stroke (mm) |

100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 10 | 14 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 |

| N | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 |

|

Stage Total Length (mm) |

420 | 520 | 620 | 720 | 820 | 920 | 1020 | 1120 | 1220 | 1320 | 1420 | 1520 |

|

Dowel Pin D1 (mm) |

50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

|

Stage Weight (kg) |

22 | 25 | 28 | 31 | 34 | 37 | 40 | 43 | 46 | 49 | 52 | 55 |

|

Sliding Table M (mm) |

250 | |||||||||||

| A |

8 |

|||||||||||

| B |

1 |

|||||||||||

|

Motion Parts Weight (kg) |

9 |

|||||||||||

LMP230-FL43-□□□-□□□-A:

|

Parameter\ Stroke (mm) |

100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 10 | 14 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 |

| N | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 |

|

Stage Total Length (mm) |

420 | 520 | 620 | 720 | 820 | 920 | 1020 | 1120 | 1220 | 1320 | 1420 | 1520 |

|

Dowel Pin D1 (mm) |

50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

|

Stage Weight (kg) |

22 | 25 | 28 | 31 | 34 | 37 | 40 | 43 | 46 | 49 | 52 | 55 |

|

Sliding Table M (mm) |

250 | |||||||||||

| A |

8 |

|||||||||||

| B |

1 |

|||||||||||

|

Motion Parts Weight (kg) |

9 |

|||||||||||

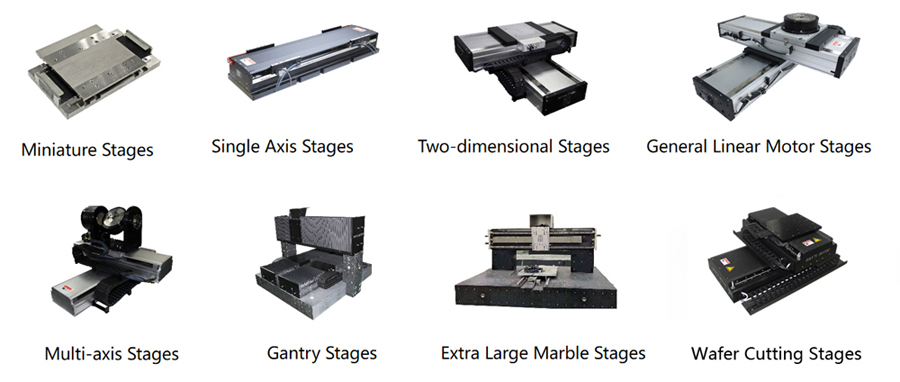

Related Stages Show:

Laser Group Show

Our Company Show

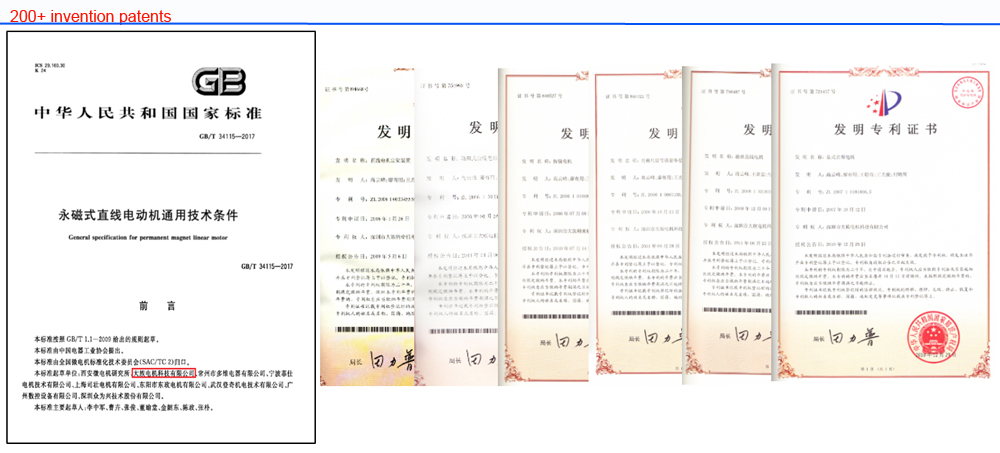

Company Qualification

Inventive Patent

Honor

Packaging & Delivery

Packaging Details.: plywood packing