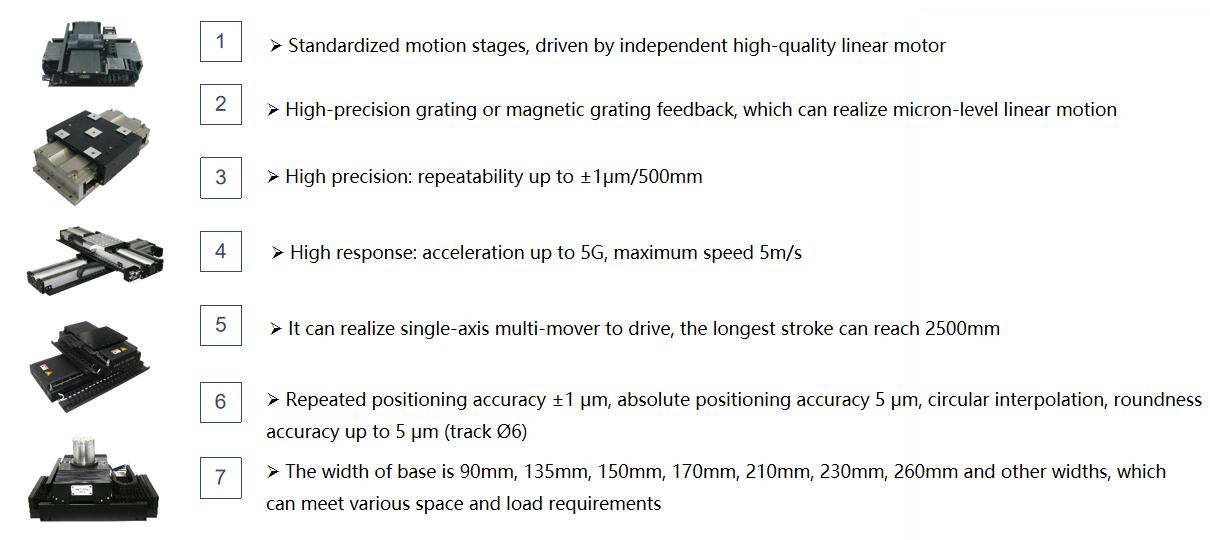

Features:

1. Adopt magnetic grating or grating feedback system for optional;

2. Long stroke 100-1200mm, and themaximum moving speed more than 5m;

3. Peak force from 1000N to 4000N for optional;

4. Allows multiple independent movers to move on the same axis;

Brand:

HAN'S MOTOROrder(MOQ):

1Products Name: Linear motor stages with precise guide systems for CNC machine (LM260 Series)

Characteristics:

Product Specifications

Motor Model/Parameter

|

|

Flat-type Motor |

|||

|

Parameter\ Motor Model |

Unit |

FL24 |

FL34 |

FL44 |

|

Continuous Force (Tmax) |

N |

393 |

589 |

785 |

|

Peak Force |

N |

1035 |

1553 |

2070 |

|

Motor Constant |

N//SqrtW |

28.9 |

35.7 |

414.4 |

|

Max.Continuous Power Dissipation |

W |

184.8 |

272.2 |

359.5 |

|

Continuous Current (Tmax) |

Arms |

4 |

4 |

4 |

|

Peak Current (1S) |

Arms |

12 |

12 |

12 |

|

Force Constant (25℃,±5%) |

N/Arms |

98.3 |

147 |

196.3 |

|

Back EMF Constant (25℃,±5%) |

Vrms/rad/s |

32.8 |

49 |

65.4 |

|

Electrical Resistance(25℃,±5%)P-P |

Ω |

5.5 |

8.1 |

10.7 |

|

Inductance(25℃,±20%)P-P |

mH |

30.0 |

45.0 |

60.0 |

|

Max Coil Temperature |

℃ |

120 |

120 |

120 |

|

Polar Distance (N-N) (360℃ Electrical cycle) |

mm |

20 |

20 |

20 |

|

Magnetic Attraction |

KN |

2.2 |

3.3 |

4.4 |

|

Mover Mass |

Kg |

4.7 |

6.9 |

9 |

Linear Motor Stages Selection (Flat-type Motor)

|

LM260-FL24-xxx-xxx-A |

|

|||||||||||

|

Parameter\ Stroke (mm) |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

|

K |

10 |

14 |

14 |

18 |

18 |

22 |

22 |

26 |

26 |

30 |

30 |

34 |

|

N |

1 |

2 |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

|

Stage Total Length (mm) |

390 |

490 |

590 |

690 |

790 |

890 |

990 |

1090 |

1190 |

1290 |

1390 |

1490 |

|

Dowel Pin D1 (mm) |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Stage Weight (kg) |

19.4 |

22.8 |

26.1 |

29.5 |

32.9 |

36.3 |

39.6 |

43.0 |

46.4 |

49.7 |

53.1 |

56.5 |

|

Sliding Table M (mm) |

170 |

|||||||||||

|

A |

8 |

|||||||||||

|

B |

3 |

|||||||||||

|

Motion Parts Weight (kg) |

6.6 |

|||||||||||

|

LM260-FL34-xxx-xxx-A |

|

|||||||||||

|

Parameter\ Stroke (mm) |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

|

K |

14 |

14 |

18 |

18 |

22 |

22 |

26 |

26 |

30 |

30 |

34 |

34 |

|

N |

2 |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

7 |

|

Stage Total Length (mm) |

450 |

550 |

650 |

750 |

850 |

950 |

1050 |

1150 |

1250 |

1350 |

1450 |

1550 |

|

Dowel Pin D1 (mm) |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Stage Weight (kg) |

21.9 |

25.2 |

28.6 |

32.0 |

35.3 |

38.7 |

42.1 |

45.5 |

48.8 |

52.2 |

55.6 |

59.0 |

|

Sliding Table M (mm) |

230 |

|||||||||||

|

A |

12 |

|||||||||||

|

B |

5 |

|||||||||||

|

Motion Parts Weight (kg) |

8.3 |

|||||||||||

|

LM260-FL44-xxx-xxx-A |

|

|||||||||||

|

Parameter\ Stroke (mm) |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

|

K |

14 |

14 |

18 |

18 |

22 |

22 |

26 |

26 |

30 |

30 |

34 |

34 |

|

N |

2 |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

7 |

|

Stage Total Length (mm) |

520 |

620 |

720 |

820 |

920 |

1020 |

1120 |

1220 |

1320 |

1420 |

1520 |

1620 |

|

Dowel Pin D1 (mm) |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Stage Weight (kg) |

24.9 |

28.3 |

31.7 |

35.0 |

38.4 |

41.8 |

45.1 |

48.5 |

51.9 |

55.3 |

58.6 |

62.0 |

|

Sliding Table M (mm) |

300 |

|||||||||||

|

A |

16 |

|||||||||||

|

B |

7 |

|||||||||||

|

Motion Parts Weight (kg) |

10.4 |

|||||||||||

Linear Motor Stages Selection (U-type Motor or Flat-type Motor)

|

|

U-type Motor |

Flat-type Motor |

||||||||

|

Parameter\ Motor Model |

Unit |

U62 |

U63 |

U64 |

U65 |

F612 |

F613 |

F614 |

FK11 |

FK22 |

|

Continuous Force (Tmax) |

N |

221 |

331 |

442 |

552 |

715 |

1562 |

1296 |

600 |

1164 |

|

Peak Force |

N |

1326 |

1988 |

2649 |

3311 |

1778 |

3767 |

2981 |

1240 |

2398 |

|

Motor Constant |

N//SqrtW |

19 |

23.5 |

27.2 |

30.5 |

42.8 |

65.7 |

58.9 |

36.1 |

50.5 |

|

Max.Continuous Power Dissipation |

W |

135.2 |

199.5 |

263.8 |

328.1 |

279.7 |

564.5 |

483.8 |

275.8 |

532.2 |

|

Continuous Current (Tmax) |

Arms |

2.5 |

2.5 |

2.5 |

2.5 |

6 |

8 |

8 |

4.8 |

4.8 |

|

Peak Current (1S) |

Arms |

15 |

15 |

15 |

15 |

18 |

24 |

24 |

11.3 |

11 |

|

Force Constant (25℃,±5%) |

N/Arms |

88.4 |

132.5 |

176.6 |

220.7 |

119 |

195.3 |

162 |

130.2 |

255 |

|

Back EMF Constant (25℃,±5%) |

Vrms/rad/s |

29.5 |

44.2 |

58.9 |

73.6 |

39.7 |

65.1 |

54 |

43.4 |

85 |

|

Electrical Resistance(25℃,±5%)P-P |

Ω |

10.3 |

15.2 |

20.1 |

25 |

3.7 |

4.2 |

3.6 |

5.7 |

11 |

|

Inductance(25℃,±20%)P-P |

mH |

19.0 |

28.5 |

38.0 |

47.5 |

50 |

64 |

64.8 |

41.4 |

82.8 |

|

Max Coil Temperature |

℃ |

120 |

120 |

120 |

120 |

120 |

120 |

120 |

120 |

120 |

|

Polar Distance (N-N) (360℃ Electrical cycle) |

mm |

84 |

84 |

84 |

84 |

42 |

42 |

42 |

32 |

32 |

|

Magnetic Attraction |

KN |

0 |

0 |

0 |

0 |

3.4 |

6.8 |

5.3 |

3.5 |

6.9 |

|

Stator Mass |

Kg |

1.9 |

2.7 |

3.6 |

4.5 |

7.4 |

13.6 |

10.8 |

5.5 |

10.4 |

|

LM260-U62-xxx-xxx-A |

|

|||||||||||

|

Parameter\ Stroke (mm) |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

|

K |

10 |

14 |

14 |

18 |

18 |

22 |

22 |

26 |

26 |

30 |

30 |

34 |

|

N |

1 |

2 |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

|

Stage Total Length (mm) |

400 |

500 |

500 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

1300 |

1400 |

1500 |

|

Dowel Pin D1 (mm) |

50 |

100 |

100 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Stage Weight (kg) |

24.8 |

29.7 |

29.7 |

39.5 |

44.4 |

49.3 |

54.2 |

59.0 |

63.9 |

68.8 |

73.7 |

78.6 |

|

Sliding Table M (mm) |

180 |

|||||||||||

|

A |

8 |

|||||||||||

|

B |

3 |

|||||||||||

|

Motion Parts Weight (kg) |

7.6 |

|||||||||||

|

LM260-U63-xxx-xxx-A |

|

|||||||||||

|

Parameter\ Stroke (mm) |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

|

K |

14 |

14 |

18 |

18 |

22 |

22 |

26 |

26 |

30 |

30 |

34 |

34 |

|

N |

2 |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

7 |

|

Stage Total Length (mm) |

480 |

580 |

680 |

780 |

880 |

980 |

1080 |

1180 |

1280 |

1380 |

1480 |

1580 |

|

Dowel Pin D1 (mm) |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Stage Weight (kg) |

29.7 |

34.6 |

39.5 |

44.4 |

49.3 |

54.2 |

59.1 |

63.9 |

68.8 |

73.8 |

78.6 |

83.5 |

|

Sliding Table M (mm) |

260 |

|||||||||||

|

A |

12 |

|||||||||||

|

B |

5 |

|||||||||||

|

Motion Parts Weight (kg) |

10.2 |

|||||||||||

|

LM260-U64-xxx-xxx-A |

|

|||||||||||

|

Parameter\ Stroke (mm) |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

|

K |

14 |

18 |

18 |

22 |

22 |

26 |

26 |

30 |

30 |

34 |

34 |

38 |

|

N |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

7 |

8 |

|

Stage Total Length (mm) |

570 |

670 |

770 |

870 |

970 |

1070 |

1170 |

1270 |

1370 |

1470 |

1570 |

1670 |

|

Dowel Pin D1 (mm) |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Stage Weight (kg) |

35.2 |

40.1 |

45.0 |

49.9 |

54.8 |

59.7 |

64.6 |

69.5 |

74.4 |

79.2 |

84.1 |

89.0 |

|

Sliding Table M (mm) |

350 |

|||||||||||

|

A |

16 |

|||||||||||

|

B |

7 |

|||||||||||

|

Motion Parts Weight (kg) |

13.2 |

|||||||||||

|

LM260-U65-xxx-xxx-A |

|

|||||||||||

|

Parameter\ Stroke (mm) |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

|

K |

18 |

18 |

22 |

22 |

26 |

26 |

30 |

30 |

34 |

34 |

38 |

38 |

|

N |

3 |

3 |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

7 |

8 |

8 |

|

Stage Total Length (mm) |

650 |

750 |

850 |

950 |

1050 |

1150 |

1250 |

1350 |

1450 |

1550 |

1650 |

1750 |

|

Dowel Pin D1 (mm) |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Stage Weight (kg) |

40.2 |

45.1 |

50.0 |

54.9 |

59.8 |

64.7 |

69.6 |

74.5 |

79.4 |

84.2 |

89.1 |

94.0 |

|

Sliding Table M (mm) |

430 |

|||||||||||

|

A |

20 |

|||||||||||

|

B |

9 |

|||||||||||

|

Motion Parts Weight (kg) |

15.9 |

|||||||||||

|

LM260-F612-xxx-xxx-A |

|

|||||||||||

|

Parameter\ Stroke (mm) |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

|

K |

10 |

14 |

14 |

18 |

18 |

22 |

22 |

26 |

26 |

30 |

30 |

34 |

|

N |

1 |

2 |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

|

Stage Total Length (mm) |

430 |

530 |

630 |

730 |

830 |

930 |

1030 |

1130 |

1230 |

1330 |

1430 |

1530 |

|

Dowel Pin D1 (mm) |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Stage Weight (kg) |

27.0 |

30.4 |

33.7 |

37.1 |

40.4 |

43.7 |

47.1 |

50.4 |

53.8 |

57.1 |

60.5 |

63.8 |

|

Sliding Table M (mm) |

210 |

|||||||||||

|

A |

12 |

|||||||||||

|

B |

5 |

|||||||||||

|

Motion Parts Weight (kg) |

13.8 |

|||||||||||

|

LM260-F613-xxx-xxx-A |

|

|||||||||||

|

Parameter\ Stroke (mm) |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

|

K |

14 |

18 |

18 |

22 |

22 |

26 |

26 |

30 |

30 |

34 |

34 |

38 |

|

N |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

7 |

8 |

|

Stage Total Length (mm) |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

1300 |

1400 |

1500 |

1600 |

1700 |

|

Dowel Pin D1 (mm) |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Stage Weight (kg) |

39.3 |

42.6 |

46.0 |

49.3 |

52.7 |

56.0 |

59.4 |

62.7 |

66.1 |

69.4 |

72.7 |

76.1 |

|

Sliding Table M (mm) |

380 |

|||||||||||

|

A |

20 |

|||||||||||

|

B |

9 |

|||||||||||

|

Motion Parts Weight (kg) |

23.9 |

|||||||||||

|

LM260-F614-xxx-xxx-A |

|

|||||||||||

|

Parameter\ Stroke (mm) |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

|

K |

14 |

14 |

18 |

18 |

22 |

22 |

26 |

26 |

30 |

30 |

34 |

34 |

|

N |

2 |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

7 |

|

Stage Total Length (mm) |

510 |

610 |

710 |

810 |

910 |

1010 |

1110 |

1210 |

1310 |

1410 |

1510 |

1610 |

|

Dowel Pin D1 (mm) |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Stage Weight (kg) |

33.3 |

36.6 |

40.0 |

43.3 |

46.7 |

50.0 |

53.3 |

56.7 |

60.0 |

63.4 |

66.7 |

70.1 |

|

Sliding Table M (mm) |

290 |

|||||||||||

|

A |

16 |

|||||||||||

|

B |

7 |

|||||||||||

|

Motion Parts Weight (kg) |

19 |

|||||||||||

|

LM260-FK11-xxx-xxx-A |

|

|||||||||||

|

Parameter\ Stroke (mm) |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

|

K |

10 |

14 |

14 |

18 |

18 |

22 |

22 |

26 |

26 |

30 |

30 |

34 |

|

N |

1 |

2 |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

|

Stage Total Length (mm) |

430 |

530 |

630 |

730 |

830 |

930 |

1030 |

1130 |

1230 |

1330 |

1430 |

1530 |

|

Dowel Pin D1 (mm) |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Stage Weight (kg) |

26.5 |

30.3 |

34.1 |

37.9 |

41.7 |

45.5 |

49.3 |

53.1 |

56.9 |

60.7 |

64.5 |

68.2 |

|

Sliding Table M (mm) |

210 |

|||||||||||

|

A |

12 |

|||||||||||

|

B |

5 |

|||||||||||

|

Motion Parts Weight (kg) |

11.9 |

|||||||||||

|

LM260-FK22-xxx-xxx-A |

|

|||||||||||

|

Parameter\ Stroke (mm) |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

|

K |

14 |

18 |

18 |

22 |

22 |

26 |

26 |

30 |

30 |

34 |

34 |

38 |

|

N |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

7 |

8 |

|

Stage Total Length (mm) |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

1300 |

1400 |

1500 |

1600 |

1700 |

|

Dowel Pin D1 (mm) |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Stage Weight (kg) |

38.3 |

42.1 |

45.8 |

49.6 |

53.4 |

57.2 |

61.0 |

64.8 |

68.6 |

72.4 |

76.2 |

80.0 |

|

Sliding Table M (mm) |

380 |

|||||||||||

|

A |

20 |

|||||||||||

|

B |

9 |

|||||||||||

|

Motion Parts Weight (kg) |

20.7 |

|||||||||||

Kindly provide below parameters to us, and we would assist you free product manual and 3D drawing and a reasonable price.

1. Effective stroke

2. Maximum speed

3. Maximum acceleration

4. Load

5. Repeatability accuracy

6. Stages structure

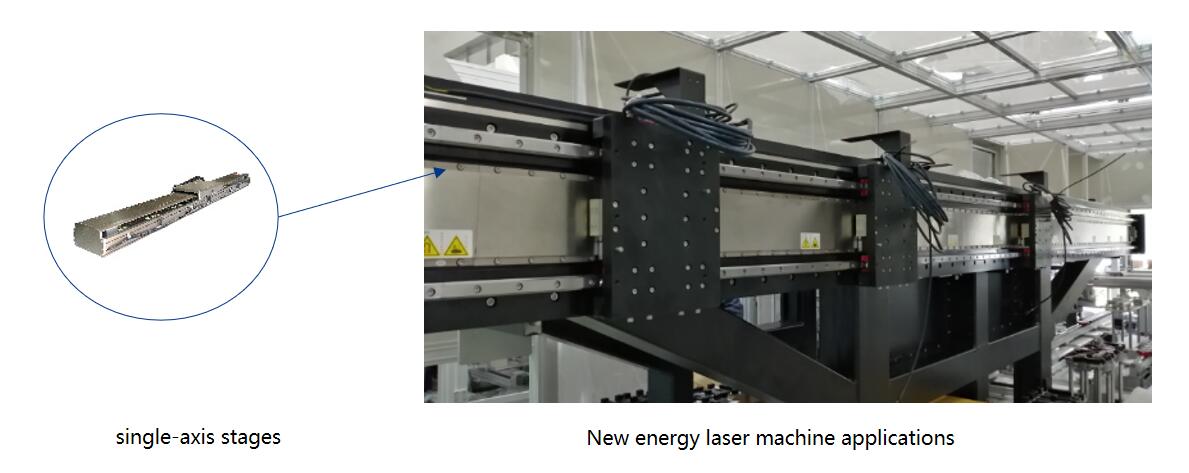

Industry Applications:

It is suitable for high precision, high straightness, low speed fluctuation, large stroke, good clean environment of panel Industry.

Packaging & Delivery:

Packaging Details.: plywood packing/Container

Port.: Shenzhen ( BY SEA, AIR,TNT, UPS, FedEx and DHL ect.)

Leading time: According to the order quantity, 20-25 days for small order and 35-40 days for bulk order