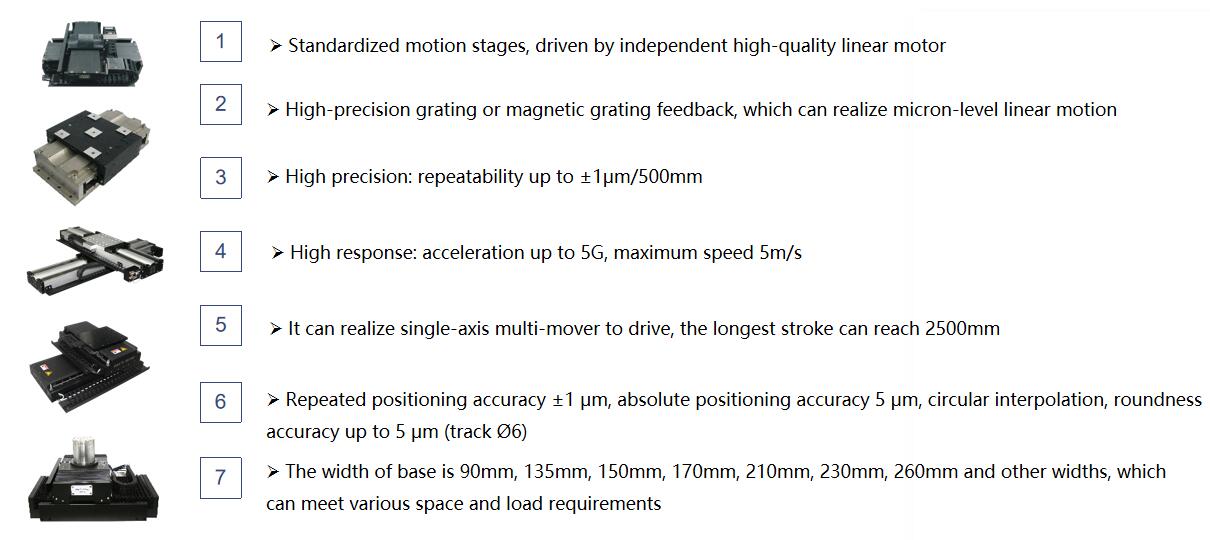

Features:

1.Standard aluminum base;

2.Driven by linear motor, the mover and stator operates without contact;

3.Grating positioning ormagnetic grating positioning feedback system for optional;

Brand:

HAN'S MOTOROrder(MOQ):

1Products Name: Iron core linear motor stages (LM135 Series)

Characteristics:

• Long stroke, the maximum stroke reaches more than 4m

• Imported ACS, ELMO, Servotronix driver for optional

• The warranty period is 12 months since you receive the goods

• Production capacity 5000 Pieces permonth

• CE, RoHS and UL certification

Product Specifications

Motor Model/Parameter

|

|

Iron Core Linear Motor |

||||

|

Parameter\ Motor Model |

Unit |

FL21 |

FL31 |

FL41 |

FJ21 |

|

Continuous Force (Tmax) |

N |

118 |

176 |

236 |

125 |

|

Peak Force |

N |

314 |

466 |

628 |

498 |

|

Motor Constant |

N//SqrtW |

13.6 |

16.5 |

19.4 |

13.6 |

|

Max.Continuous Power Dissipation |

W |

75.2 |

114.2 |

147.8 |

84.2 |

|

Continuous Current (Tmax) |

Arms |

4 |

4 |

4 |

2.2 |

|

Peak Current (1S) |

Arms |

12 |

12 |

12 |

9 |

|

Force Constant (25℃,±5%) |

N/Arms |

29.5 |

44 |

59 |

56.8 |

|

Back EMF Constant (25℃,±5%) |

Vrms/rad/s |

9.8 |

14.7 |

19.7 |

18.8 |

|

Electrical Resistance(25℃,±5%)P-P |

Ω |

2.4 |

3.4 |

4.4 |

8.2 |

|

Inductance(25℃,±20%)P-P |

mH |

9.0 |

13.5 |

18.0 |

26 |

|

Max Coil Temperature |

℃ |

120 |

120 |

120 |

120 |

|

Polar Distance (N-N) (360℃ Electrical cycle) |

mm |

20 |

20 |

20 |

20 |

|

Magnetic Attraction |

KN |

0.68 |

0.98 |

1.3 |

0.75 |

|

Mover Mass |

Kg |

1.6 |

2.3 |

3 |

1 |

Linear Motor Stages Selection

|

LM135-FL21-xxx-xxx-A |

|

|||||||||||

|

Parameter\ Stroke (mm) |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

|

K |

10 |

14 |

14 |

18 |

18 |

22 |

22 |

26 |

26 |

30 |

30 |

34 |

|

N |

1 |

2 |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

|

Stage Total Length (mm) |

380 |

460 |

560 |

660 |

760 |

860 |

960 |

1060 |

1160 |

1260 |

1360 |

1460 |

|

Dowel Pin D1 (mm) |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Stage Weight (kg) |

8.7 |

10.1 |

11.5 |

12.8 |

14.2 |

15.7 |

16.9 |

18.4 |

19.8 |

21.1 |

22.5 |

24.0 |

|

Sliding Table M (mm) |

170 |

|||||||||||

|

A |

8 |

|||||||||||

|

B |

3 |

|||||||||||

|

Motion Parts Weight (kg) |

3.6 |

|||||||||||

|

LM135-FL31-xxx-xxx-A |

|

|||||||||||

|

Parameter\ Stroke (mm) |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

|

K |

10 |

14 |

14 |

18 |

18 |

22 |

22 |

26 |

26 |

30 |

30 |

34 |

|

N |

2 |

2 |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

|

Stage Total Length (mm) |

430 |

530 |

630 |

730 |

830 |

930 |

1030 |

1130 |

1230 |

1330 |

1430 |

1530 |

|

Dowel Pin D1 (mm) |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Stage Weight (kg) |

10.7 |

12.2 |

13.6 |

14.9 |

16.3 |

17.8 |

19.0 |

20.5 |

21.9 |

23.2 |

24.7 |

26.1 |

|

Sliding Table M (mm) |

240 |

|||||||||||

|

A |

12 |

|||||||||||

|

B |

5 |

|||||||||||

|

Motion Parts Weight (kg) |

4.7 |

|||||||||||

|

LM135-FL41-xxx-xxx-A |

|

|||||||||||

|

Parameter\ Stroke (mm) |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

|

K |

14 |

14 |

18 |

18 |

22 |

22 |

26 |

26 |

30 |

30 |

34 |

34 |

|

N |

2 |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

7 |

|

Stage Total Length (mm) |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

1300 |

1400 |

1500 |

1600 |

|

Dowel Pin D1 (mm) |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Stage Weight (kg) |

13.2 |

14.4 |

15.9 |

17.2 |

18.6 |

20.0 |

21.3 |

22.7 |

24.2 |

25.5 |

26.9 |

28.3 |

|

Sliding Table M (mm) |

310 |

|||||||||||

|

A |

12 |

|||||||||||

|

B |

5 |

|||||||||||

|

Motion Parts Weight (kg) |

5.9 |

|||||||||||

|

LM135-FJ21-xxx-xxx-A |

|

|||||||||||

|

Parameter\ Stroke (mm) |

100 |

200 |

300 |

400 |

500 |

600 |

700 |

800 |

900 |

1000 |

1100 |

1200 |

|

K |

10 |

14 |

14 |

18 |

18 |

22 |

22 |

26 |

26 |

30 |

30 |

34 |

|

N |

1 |

2 |

2 |

3 |

3 |

4 |

4 |

5 |

5 |

6 |

6 |

7 |

|

Stage Total Length (mm) |

380 |

480 |

580 |

680 |

780 |

880 |

980 |

1080 |

1180 |

1280 |

1380 |

1480 |

|

Dowel Pin D1 (mm) |

50 |

100 |

150 |

200 |

250 |

300 |

350 |

400 |

450 |

500 |

550 |

600 |

|

Stage Weight (kg) |

8.7 |

10.2 |

11.6 |

12.8 |

14.3 |

15.6 |

17.8 |

18.5 |

19.9 |

21.1 |

22.6 |

23.9 |

|

Sliding Table M (mm) |

190 |

|||||||||||

|

A |

8 |

|||||||||||

|

B |

3 |

|||||||||||

|

Motion Parts Weight (kg) |

3.3 |

|||||||||||

Kindly instruct us your requirements, you can provide below parameters to our engineer, free product manual and 3D model and a reasonable price will send to you anytime.

1. Effective stroke

2. Maximum speed

3. Maximum acceleration

4. Load

5. Repeatability accuracy

6. Straightness

7. Protectivefully sealed or semi-protected

Module several types:

Industry Applications:

Competitive motion stages, it is widely apply to heavy load, high acceleration, and high speed equipment.

Packaging & Delivery:

Packaging Details.: plywood packing

Price terms: FOB Shenzhen

Leading time: According to the order quantity, 5-7 days for sample order and 20 days for bulk order