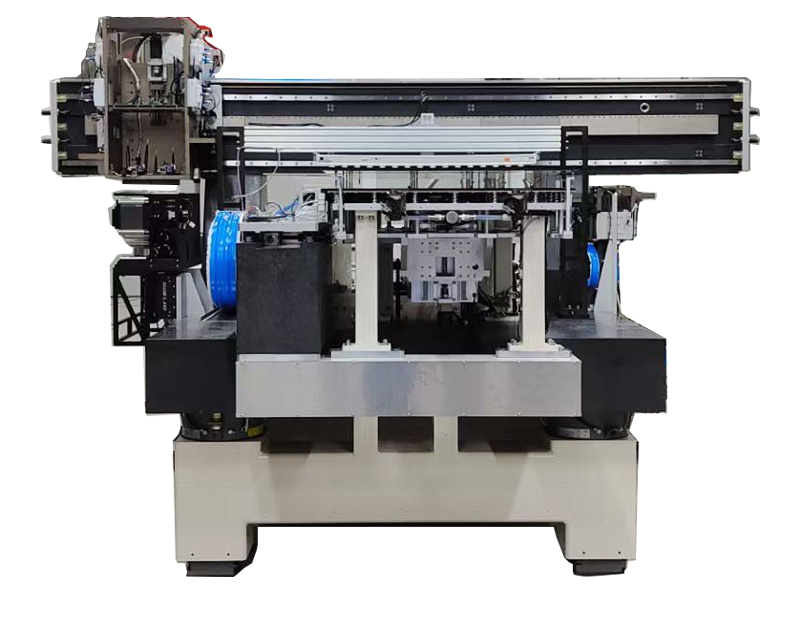

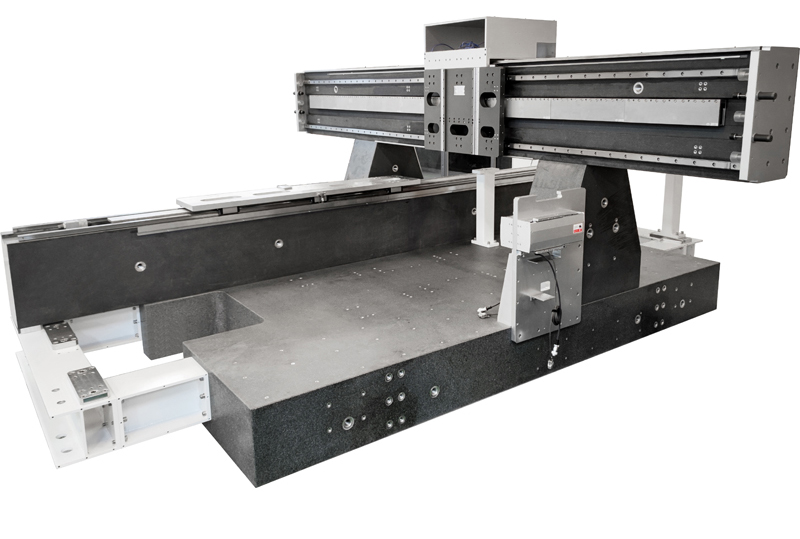

Linear motor stage is a workbech that mainly can achieve accurate movement in X,Y,Z,θ direction, with its rapid response, accurate positioning and high reliability. It is widely applied to high-speed automation equipment, mechanical arm, optical contrast, positioning detection precision measuring system, electronics and semiconductor processing equipment (semiconductor wafer cutting, solid crystal machine and bonding machine), laser processing equipment (laser marking, laser cutting, laser engraving, laser drilling, laser marking) and so on.

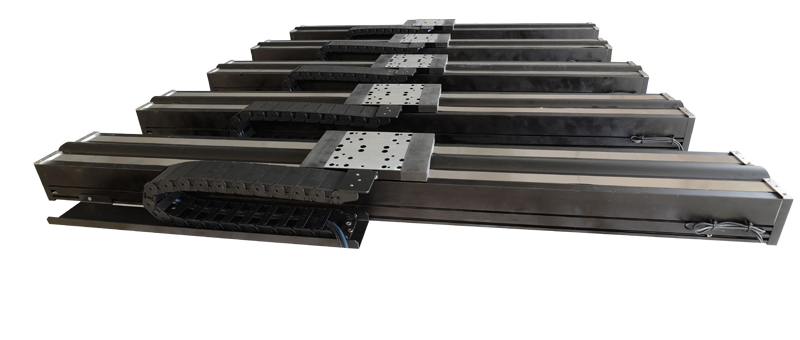

High speed linear stage include ironless motor, iron core motor and tubular motor stages, base width have 135mm, 150mm, 170mm, 210mm, 230mm, 260mm.

Standard motorized linear stages provide the following effective stroke: 100mm, 200mm, 300mm, 400mm, 500mm, 600mm, 700mm, 800mm, 900mm, 1000mm, 1100mm, 1200mm, 1500mm, 2000mm.

HAN'S Motor based on mature motor design and application technology, which introduces professional technology, talents and equipment, focuses on the development of high-precision linear motor stage. High precision xy linear stage products and application technology developed rapidly, has become one of the main products of HAN’S Group.

Linear motor module features:

Driven by linear motor

Optical grating positioning or magnetic grating positioning

High stability, high reliability, high response speed

High precision, high acceleration, high moving speed

Motor mover and stator runs without contact, no backlash error

Smooth movement, no wear, little maintenance, long service life

Compact modular design, easy to expand, long service life

Quickly assemble to mechanical arm, xy motion stage and gantry stages

Allows multiple independent movers on one axis

Long travel linear stage, the maximum stroke reaches more than 4m

The maximum moving speed is more than 5m, greatly improve production efficiency.

Integrated stages linear actuators eliminate separate connection mechanisms, belts, gears and associated assembly work

Homing hardware operation and software process limits can eliminate tedious external limit switches