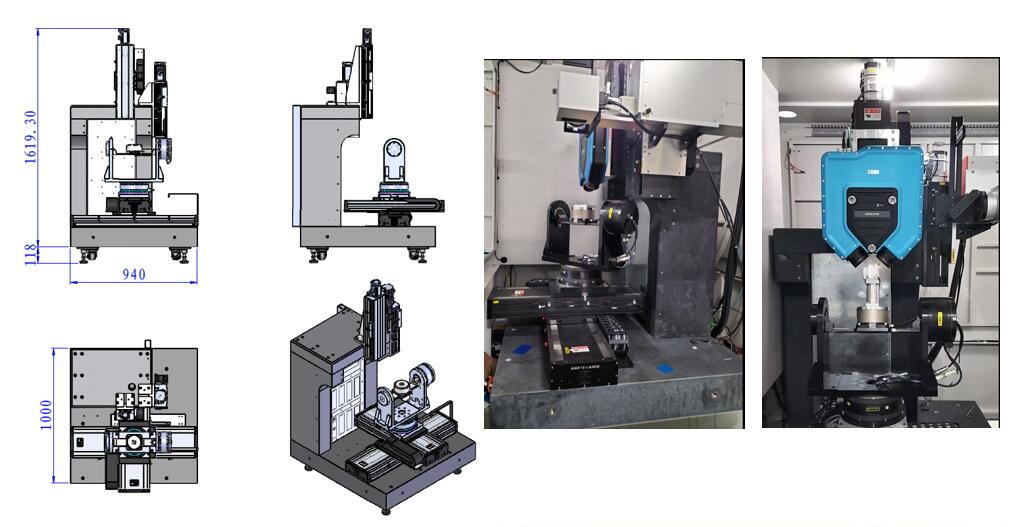

Product Features:

The marble base is matched with high-rigidity linear guide rails and high-precision optical grating feedback, which can ensure stable accuracy of product for a long time.

X-axis, Y-axis, C-axis, B-axis, A-axis all are driven by direct drive motor, which can ensure high acceleration and sub-micron precision. X-axis,Y-axis was driven by linear motor, which is built into a two-dimensional cross structure. C-axis, B-axis, A-axis direct drive by DDR, which is built into a swing head structure. Z1-axis, Z2-aixs was driven by servo motor with brake, power-off protection.

X-axis、Y-axis max.speed is 1m/s, the acceleration is 1G, and the repeat positioning accuracy is ±1um.

Rotary axis repeat positioning accuracy ±1.5arcsec.

Parameter:

|

Item |

X-axis |

Y-axis |

Z1-axis |

Z2-axis |

C-axis |

B-axis |

A-axis |

|

Stroke (mm) |

500 |

300 |

300 |

150 |

100°-+40° |

100°-+40° |

360° |

|

Max.Speed (mm/s) |

1000 |

1000 |

500 |

500 |

500rpm |

300rpm |

500rpm |

|

Repeat Accuracy (μm) |

±1 |

±1 |

±0.01 |

±0.01 |

±1.5arc sec |

±1.5arc sec |

±1.5arc sec |

|

Acceleration(g) |

0.5 |

0.5g |

0.5 |

0.5 |

|

|

|

|

Load (kg) |

|

|

30 |

30 |

|

|

|

|

Z1-axis and Z2-axis positioning accuracy≤0.01mm; XY-axis perpendicularity≤0.01mm; Z1 & XY axis flat perpendicularity≤0.01mm |

|||||||

|

Any position in space and theoretical deviation ≤0.04mm |

|||||||

Application:

Six-axis motorized linear stage can meet high-speed, high-acceleration, and high-precision

product customization requirements. It can be suitable for glass flake inspection, glass cutting, laser processing (shaped marking), wafer inspection, CCD imaging, three-dimensional profile scanning and other high-end manufacturing industries.

Application scenarios:

It can realize fast and accurate point-to-point operation within six-dimensional range of solid space.

It can be matched with line scan cameras, lasers for flying shooting, flying marking and other processing actions.

Use the six-axis linkage high speed linear stage mode to realize the interpolation movement of any curve within the stroke range.

Hardware configuration:

X/Y axis——high-precision linear stage(with optical grating feedback + linear drive)

A/B/C axis——DDR dc torque motor stage (with optical grating feedback + DDR driver)

Z1/Z2 axis——servo module (servo motor+ servo drive + full closed loop control)

Multi-axis motion controller: (including eight axis pulse output + eight axis analog output)

Limit and origin sensor: equipped with grating limit and grating origin and photoelectric sensor in reserve

Visual system with various application scenarios (optional)

Software configuration:

Precision motorized linear stages is equipped with each axis drive and controller debugging software and instructions, various interpolation trajectory motion interfaces, and provide positioning compensation, visual calibration, precision measurement, provide early guidance training and assisted development services, and provide software development services.

Accuracy compensation of motorized positioning stages:

Linear error of motion axis

Verticality error of motion axis

Assembly error of rotation axis in the rotation center