Why the torque motor is different with other similar motors?

Torque motors normally are different from other similar motors due to their wide diameter to allow for high levels of torque, and their thermal performance to allow their continuous operation while drawing high current in a stalled state.

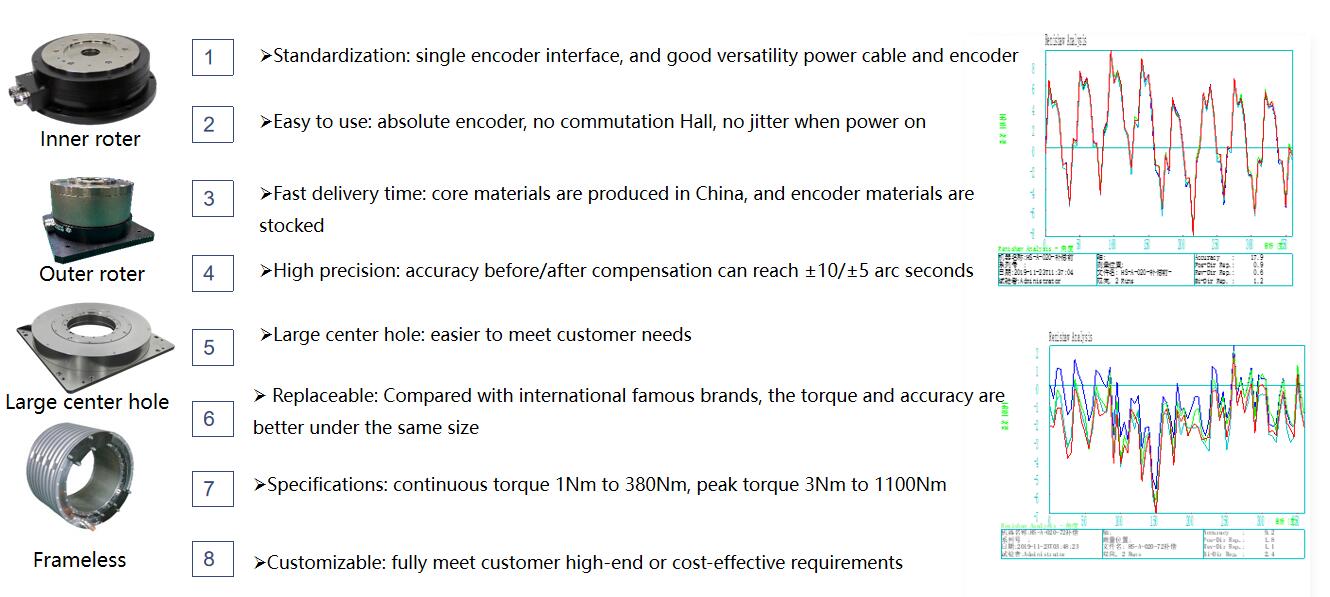

Compared with linear motors , torque motors are a type of “ frameless ” motor . This means that the motor does not include a housing , bearings , or feedback device . These components can be selected by the machine builder and optimized according to the required performance , or purchased as part of an assembly. Contrary to traditional drives , the sizing and selection of a torque motor is purely based on torque, not power. Fundamentally, the peak torque determines the maximum torque that the motor physically produces and the continuous torque defines the a mount of torque, which the motor can continuously supply.

DDR motor can be used asactuators for direct-drive mechanisms in some situations where otherwise geared electric motors would be used: for example,in motion control systems or servo mechanisms. Actuators are hardware devices that converts the controller command signal into a change in a physical parameters.

DC direct drive motors ability to directly drive applications. There is no need for transmission/gearbox. The moving rotor of the torque motor is glued or clamped directly on the driven part.

|

Type |

Application |

Type |

Advantage |

Disadvantage |

|

Frame torque motor |

Apply to industrial automation, semiconductor, medical and other industries |

inner rotor torque motor |

Compared with the outer rotor, the inner rotor motor is small size, light weight and small inertia, and is also suitable for high-speed and high-frequency motion

|

small inertia. It is recommended to use an outer rotor motor for large loads

|

|

outer rotor torque motor

|

Large inertia, better rigidity for low-speed motion, it is not suitable for high-speed, high-frequency motion

|

The price is slightly expensive due to special design structure

|

||

|

Frameless torque motor |

Only rotors and stators, which need to be assembled into motor modules by customers. Apply to machine tools and robots

|

Water-cooling motors

|

water cooling device with good heat dissipation, and the same size motor have double torque, which is suitable for machine tools

|

Customer need to have the ability to design and install, it requrie an extra cooling device

|

|

Natural cooling

|

It can be apply to non-standard and compact applications, such as robot joints |

Customer need to have the ability to design and install

|

How the torque motor works?

High torque motors can be fitted with a closed loop control mechanism, like conventional servo motors, but the concept and shape is different. Because of the shape, the torque motor generates a lot of torque, but its RPM is limited. On the other hand, conventional servo motor can reach much higher RPM but generates far less torque.Therefore,It is often fitted with a gearbox to reach the desired speed to torque ratio , but this gearing does reduce efficiency and accuracy.

Indirect drive torque motors , the motor directly drives the load which eliminates the use of a

transmission or a gearbox. As a result, the amount of moving parts in the system is reduced tremendously, which also increasing the effciency and creating a quiet and high dynamic operation . Therefore , direct drive technology achieves a very high lifetime. Direct drive motors are ideal for applications where a high positioning accuracy is needed and small size , low weight , minimum power and optimal speed control is desired . It is combined with a stator and rotor.