Introduction

Today, every industry has their equipment running through machines and every machine is discreetly dependent on some motor. The most unique motor for industrial machinery drives is the high torque DC motor. It is possible it does not always get the same limelight as other esteemed inventions of our age, but its importance is explicitly connected to many processes.

Torque motors exist in so many applications from robotic joints to large industrial machines, allowing for fluid and precise motion. What distinguishes torque motors is the ability to generate substantial torque starting from low speeds. Conventional motors create torque typically with the help of gear boxes but high torque motors deliver torque inherently.

This feature offers a level of mechanical simplicity and dependability appreciated by many engineers and other industries. Before we share normal uses of torque motors in the next blog, we must first understand what torque motors are, what they can do, and what the advantages are.

Features of Torque Motors

When someone hears about a torque motor for the first time, they may wonder what sets it apart. A torque motor, especially a high torque DC motor, is designed in such a way that it can create continuous torque over a wide range of speeds. Some of its main features include:

Direct Drive Capability

One of the standout features of torque motors is that they can often operate without the need for gears or mechanical transmission systems. This makes the motor design simpler and cuts down on wear and tear over time.

High Torque at Low Speeds

It needs an external system to reach a high torque output, while other torque motors generate it directly. This allows smoother control and avoids unnecessary complexity.

Precision in Control

These motors are often chosen for tasks where precision is critical. The direct response of a torque motor makes it ideal for robotics, automation, and motion control tasks.

Durability

Because torque motors don’t depend heavily on gear systems, fewer mechanical parts are subject to friction and damage. This increases the overall life span of the equipment.

Low Maintenance Needs

With simpler internal design, these motors typically require less frequent servicing compared to other heavy-duty options.

Taken together, these features explain why torque motors are highly reliable, practical, and favored across industries that need both accuracy and strength.

Advantages of High Torque DC Motors

The features of the motor naturally lead to advantages, but when placed in real-life applications the high torque DC motor brings even greater benefits. Let’s take a closer look at why industries continue to prefer these motors:

Efficiency in Operation

Since torque motors can eliminate the need for gearboxes, energy losses are reduced. This helps in cutting operational costs over time.

Smooth Motion

The absence of gear backlash results in a smoother movement, which is vital for applications like medical imaging machines or robotics arms.

Compact Design

Because of their mini size they don’t require large gear assemblies, the overall system size can be smaller. This compactness is very useful when the space is limited.

High dependability

When processes are very important, dependability is just as important as performance. It is recommended to choose high power motors because they are built to last and to keep their output stable.

Control systems that work better

Torque motors are perfect for fields where even a small mistake can have big effects because they work very accurately.

Because of these benefits, engineers still choose torque motors over other options when making sensitive machinery.

Common Applications of Torque Motors

Now comes the question many people ask: where exactly are these motors used? The answer is surprisingly broad. The high torque DC motor finds a home in many industries, and each use case shows a different side of its value.

New Energy

Torque motors are applied in renewable energy equipment that requires long service life and stable output. Their durability makes them well-suited for demanding operating conditions.

Photovoltaics

In solar panel production and tracking systems, torque motors ensure precise alignment and smooth positioning, helping to maximize energy efficiency and system reliability.

Semiconductors

Semiconductor manufacturing involves processes such as wafer handling and lithography that demand sub-micron precision. Torque motors provide stable motion control, reducing vibration and ensuring process accuracy.

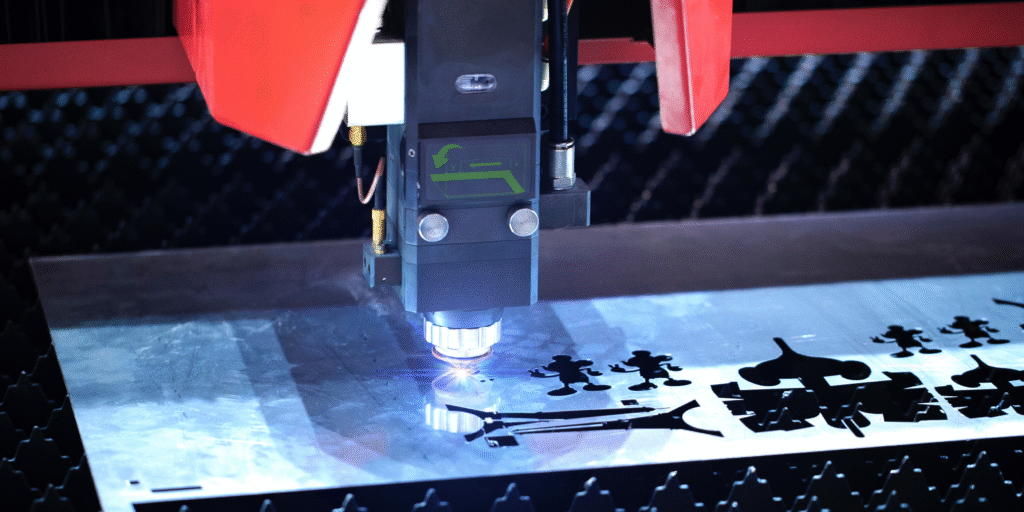

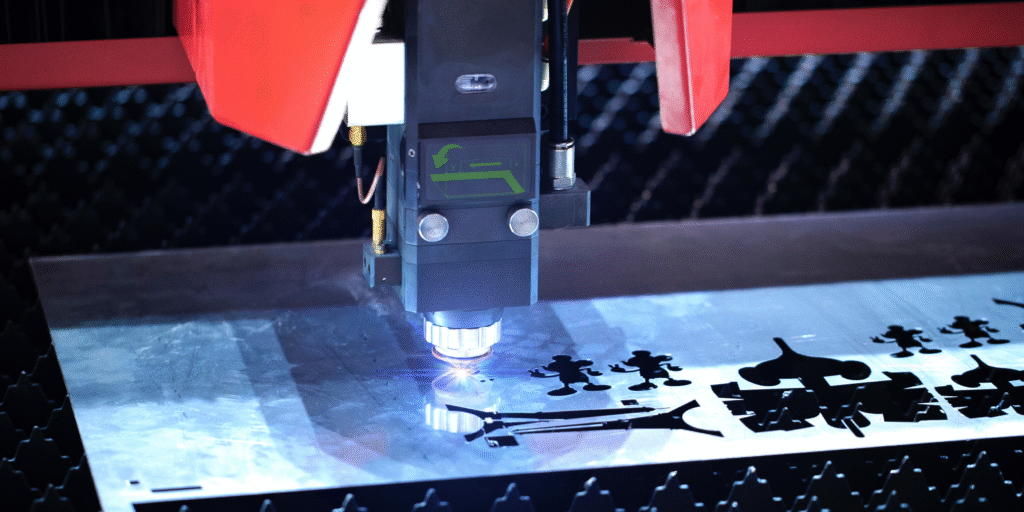

Laser Precision Machining

Laser cutting, drilling, and engraving machines rely on torque motors for smooth, backlash-free rotation. This stability directly affects machining quality and consistency.

Printing

In modern printing machinery, torque motors deliver constant speed and precise registration. This enables high-resolution output while reducing mechanical wear compared to conventional drive systems.

Biomedical Engineering

Torque motors are used in medical devices that require smooth and accurate movement, such as imaging systems, diagnostic equipment, and surgical instruments. Their reliability is especially important in clinical environments.

Precision Rotary and Indexing Tables

Direct-drive torque motors are widely used in rotary and indexing tables, providing high positioning accuracy and eliminating the need for mechanical gears. This results in reduced maintenance and higher efficiency.

CNC Machine Tools

In CNC machining centers, torque motors provide high torque at low speeds with excellent control. This improves surface finish, machining accuracy, and overall productivity.

Key Takeaways

Torque motors have become a key component across multiple industries where precision, stability, and efficiency are essential. From energy and semiconductor manufacturing to medical and machining applications, their role continues to expand as technology advances.

Why Industries Continue to Choose Torque Motors

Machines are used in every business today, and each machine relies on its motor in silence. There are many kinds of motors used in factories, but the high speed DC motor is one of the most important ones.

It might not get as much notice as other modern inventions, but it is an important part of a huge number of processes. Torque motors are used in a lot of different things, from robotic joints to big industrial tools. Without them, it would be hard to move things smoothly and precisely.

Another key factor is flexibility. The high torque DC motor can adapt to small-scale precision tasks as well as large-scale industrial operations.

Frequently Asked Questions(FAQ)

Q1: What makes a high torque DC motor different from other DC motors?

A1: A high torque DC motor is designed to deliver strong torque at lower speeds without relying on gearboxes. This makes it more direct, efficient, and reliable.

Q2: Do torque motors need regular maintenance?

A2: Compared to motors with gear assemblies, torque motors usually need less maintenance. However, like all machines, occasional checks and servicing are still important.

Q3. Are torque motors used in heavy-duty fields?

A3: Yes, torque motors are used in a lot of heavy-duty fields, like aerospace, military, and manufacturing, because they last a long time, are reliable, and work well.

Q4: Do torque motors use little energy?

A4: Yes, torque motors are direct drive motors. This means they lose very little energy, which makes them more energy efficient overall.

Q5: Where can I buy a reliable high torque DC motor?

A5: You can source high-quality options from trusted suppliers like Hans Motor, known for reliable and performance-driven motor solutions.

Conclusion

Due to its many designs and operations, torque motors can be applied to many industrial and commercial uses. By knowing the operant properties of each type, engineers can better utilize the right motor in the right operating conditions and environment.