Most of the operations in our automated world, which contains factories, and high-tech machines, are based on movements. It doesn’t matter whether it’s a robotic arm taking apart the smallest components or a CNC machine which is cutting the parts with the precision of microns, there should always be a method to change electrical energy into mechanical energy of a proper control. One of the most amazing technologies that makes this easy and direct transfer of energy is a linear drive motor, which works as a straight-line direct-drive system instead of a spinning one. To an inexperienced person, the idea might sound intricate, however, when its explanation is given stepwise, the process inside is not as confusing as it looks.

From Rotation to Straight Motion

Traditional motors have been specifically made for a rotational movement. A ceiling fan or the motor in a washing machine are the perfect examples: they turn around a shaft. However, many industrial processes require that the machine move only in a straight line. Previously, engineers had to use rotary motors with belts, pulleys, gears, or lead screws to convert this rotation into linear movement. These mechanical conversions, although they are still effective, have an inherent problem that they cause friction, wear, and small errors known as backlash.

The breakthrough was the concept of flattening a motor; by redesigning it into a linear drive motor, engineers eliminated the need for belts and screws while improving accuracy and control.Removing the intermediate gears or screws improved motion accuracy and control. That flattened motor is what we call a linear-type motor system today.

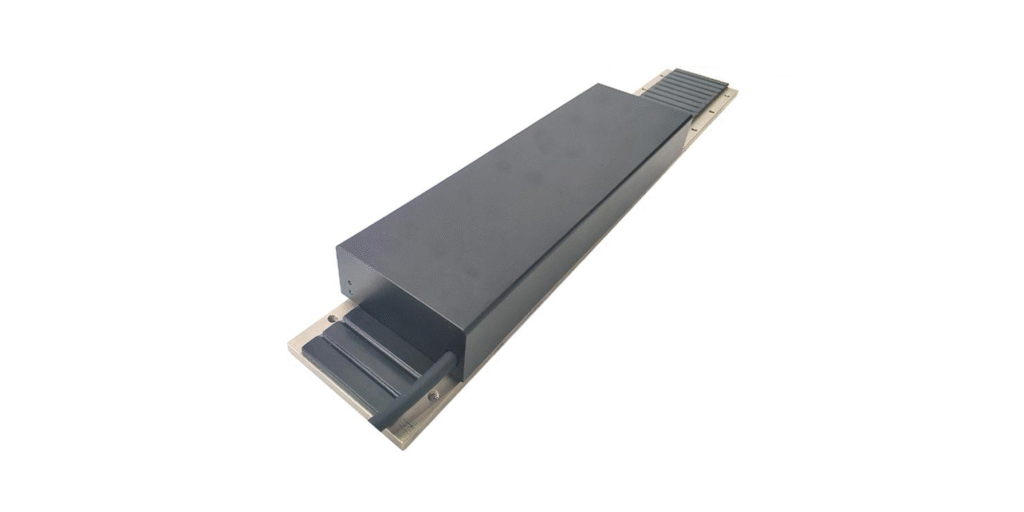

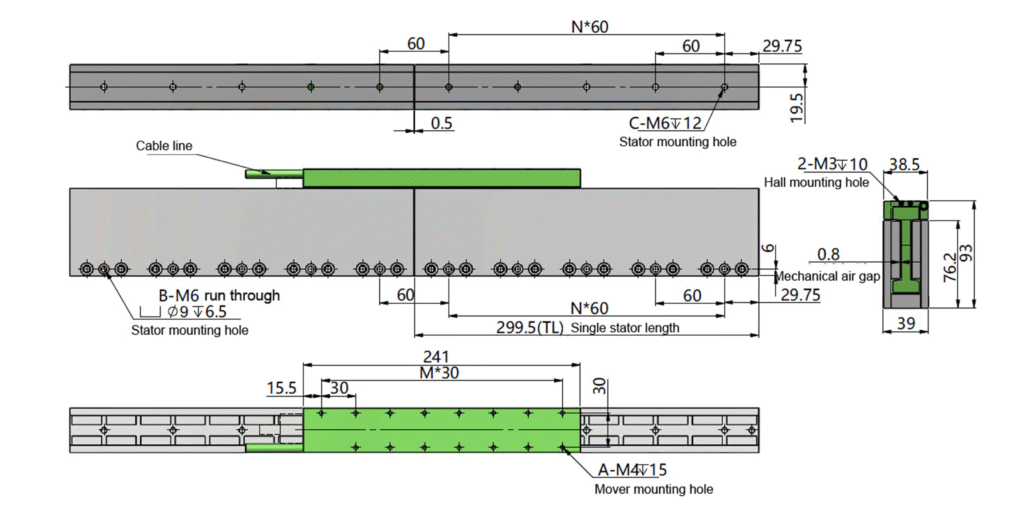

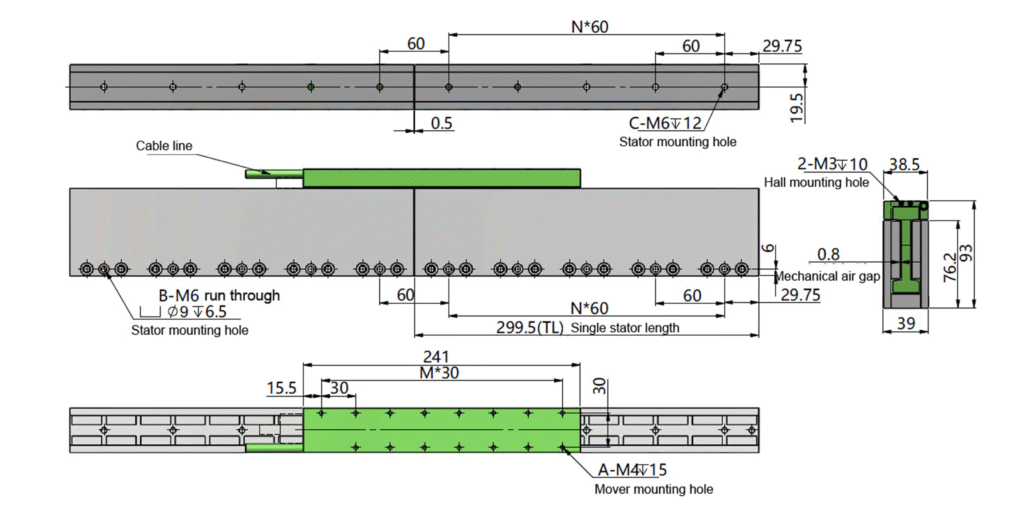

The Essential Structure

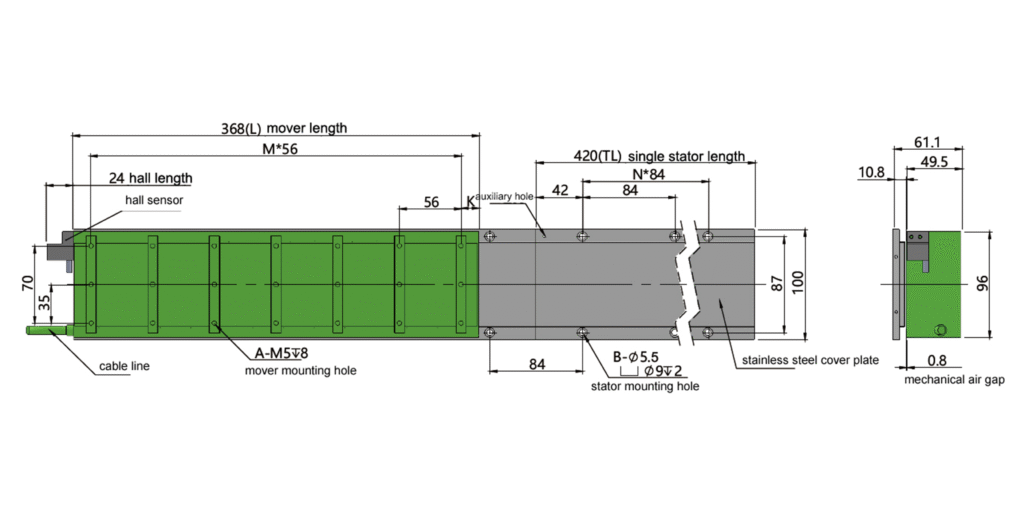

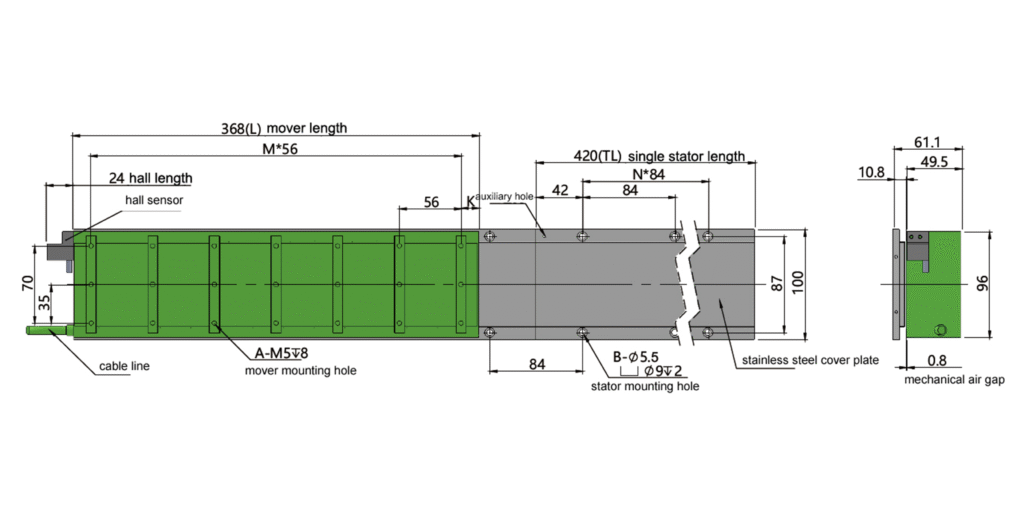

Even though it seems different from traditional rotary designs, the understanding of the anatomy of this straight-motion motor is just as surprising humanly. Its main parts are:

- Magnetic Base: It is a fixed track that has either permanent magnets or iron cores placed in a repeated pattern. The moving element creates the magnetic field with which it can interact.

- The slider or forcer: It is the part that moves, it was installed with wires coiled in it. When current is made to flow through these coils, a magnetic field is developed which is either attractive or repulsive to the base.

- Drive Electronics: It is a controller that supplies electric currents in carefully timed phases. The slider moves smoothly by turning on and off the current at precisely the right times.

- Feedback Sensors: Position sensors, mostly optical encoders, always keep track of the position of the slider. The information is then given back to the controller which ensures that the movement is exact.

- Support System: Bearings or guide rails are there to assist the moving part while keeping it in its correct position and cooling elements are used to manage the heat that arises during operation.

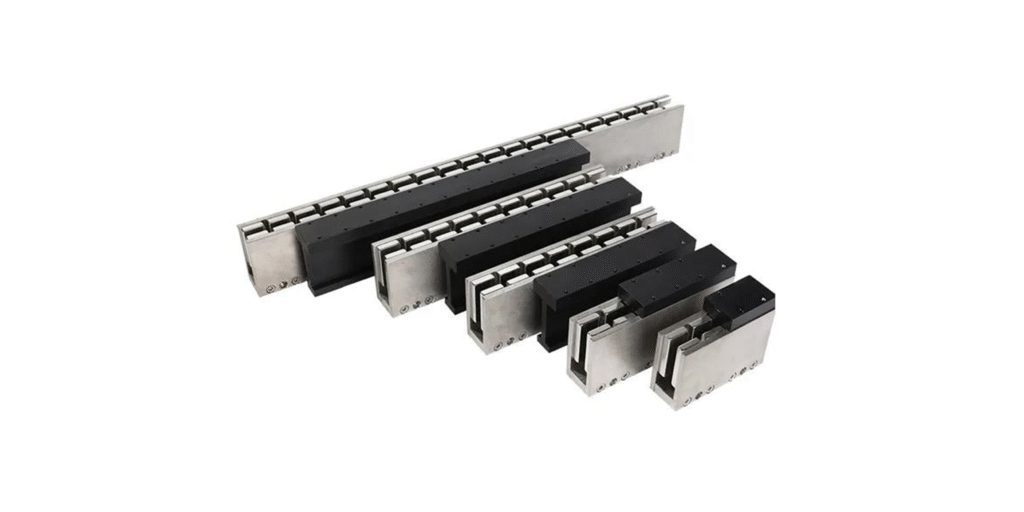

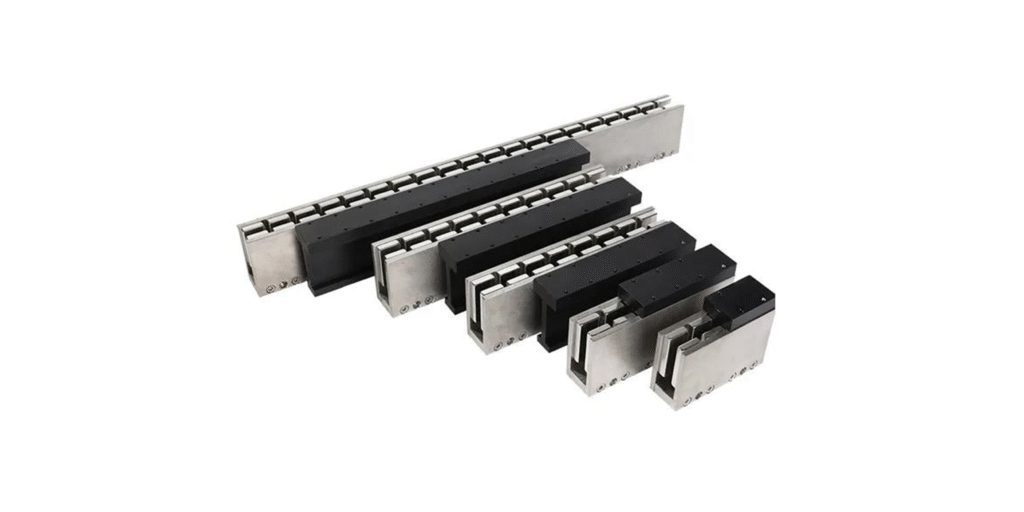

Types of Designs

Not everything is identical in the systems world. Different versions were available and the engineers chose among them depending on the application.

- Ironless Designs: A power train without a heavy slider iron core is the lifeline of these designs. They run at high speed, create less heat, and deliver very smooth motion. These are perfect for speed and gentleness-demanding fields like electronics and medical devices.

- Iron-Core Designs: The slider is the iron backbone of which forcibly increases the thrust force. They can be used to move heavy loads, however, are likely to create drag and heat at the same time.

- Tubular Designs: The motor is not on the flat track, but is round in shape with a cylindrical mover sliding inside. Such a design saves space and provides the best protection from dust or debris.

- Voice Coil Actuators: These fast-acting short stroke copies are typically found in speakers, camera focusing systems, or precision instruments.

Why They Matter

The linear drive motor is on the rise and has transformed modern industry. Some of their main advantages are:

- Exactness Without Backlash: In these drives there are no gears or screws which may cause a loss of accuracy, thus the accuracy of the whole system is higher.

- High Speed and Acceleration: They can be very quick in their actions to finish what they have started turning into essential in a sector like pick-and-place robotics and semiconductor manufacturing.

- Smoothness and Reliability: Because of the small number of mechanical parts, these drives have low maintenance, and their service life is longer.

- Compact and Flexible: They are a major help in the simplification of the machine design and can thus be lighter and take up less space than the old systems.

Where You’ll See Them in Action

These linear drive motor systems quietly power many parts of our world:

- CNC machining centers where tools move with micrometer accuracy

- Semiconductor fabrication plants, where wafers must be aligned without vibration.

- Robotics, where parts are picked, placed, and assembled in milliseconds

- Printing and packaging machines where speed and synchronization are essential

- The precise positioning of medical imaging or laboratory equipment is crucial for patient safety.

Despite operating in the background, they serve as the foundation of automation, manufacturing, and high-tech industries.

Operating Principle of Linear Motors

Electromagnetic interaction forms the core of the operating principle. The current that flows through the coils on the moving slider creates a magnetic field. This field interacts with the field produced by the permanent magnets attached to the track, thereby generating a thrust force that moves the slider along. The sensors that take the measurements of the position are always present. At the same time, the drive electronics use the current to provide the desired speed, accuracy, and stability.

Conclusion

Such motors use the magnetic forces to provide extremely precise locations and are essential in today’s automated and CNC-controlled environments. By learning how their devices’ inner parts work together, one can boost machine output and make operations smoother. Precision manufacturers around the world highly regard their products, which range from small direct-drive systems to heavy industrial actuators.