Products

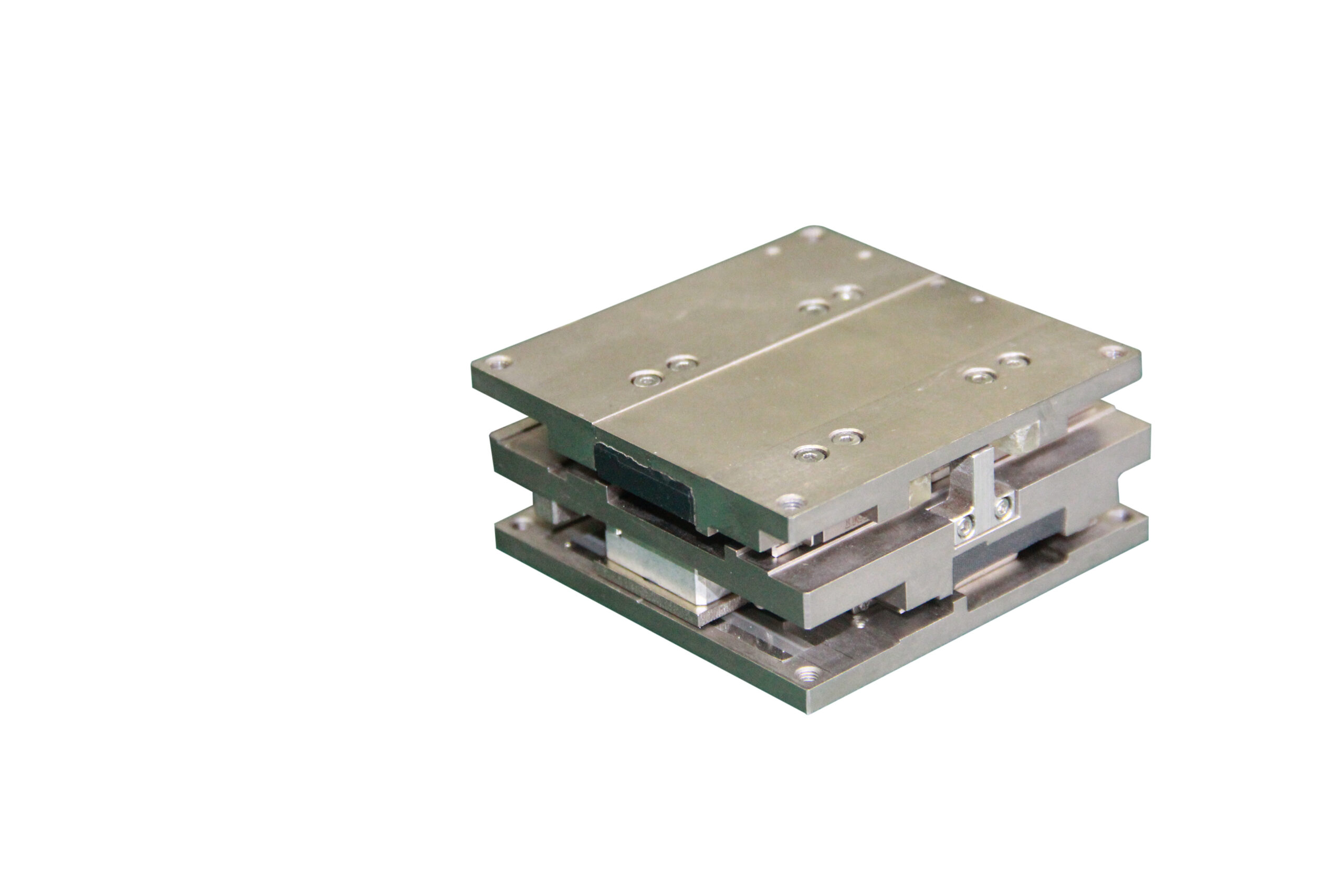

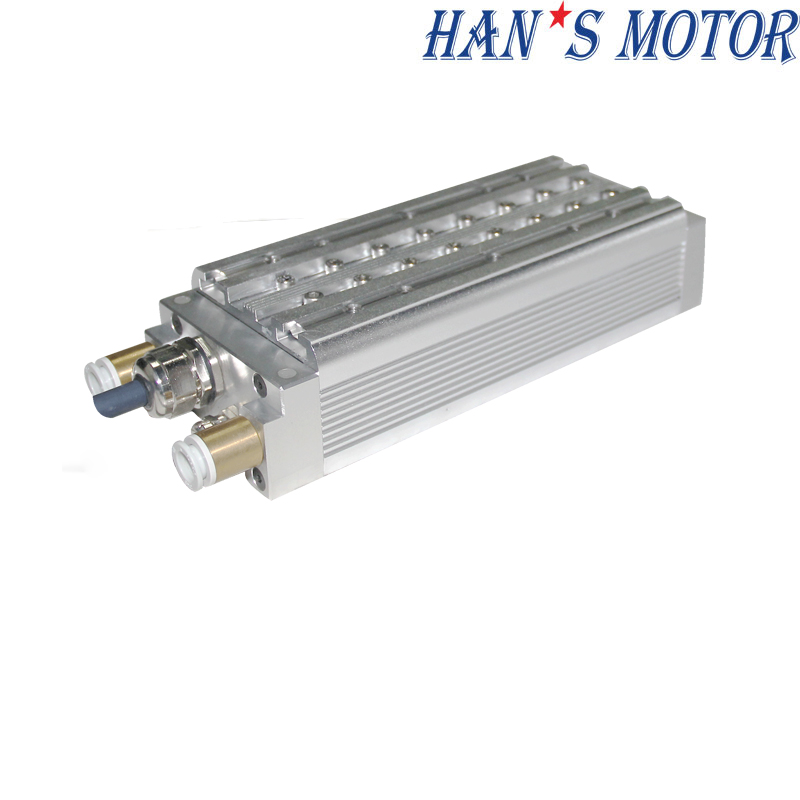

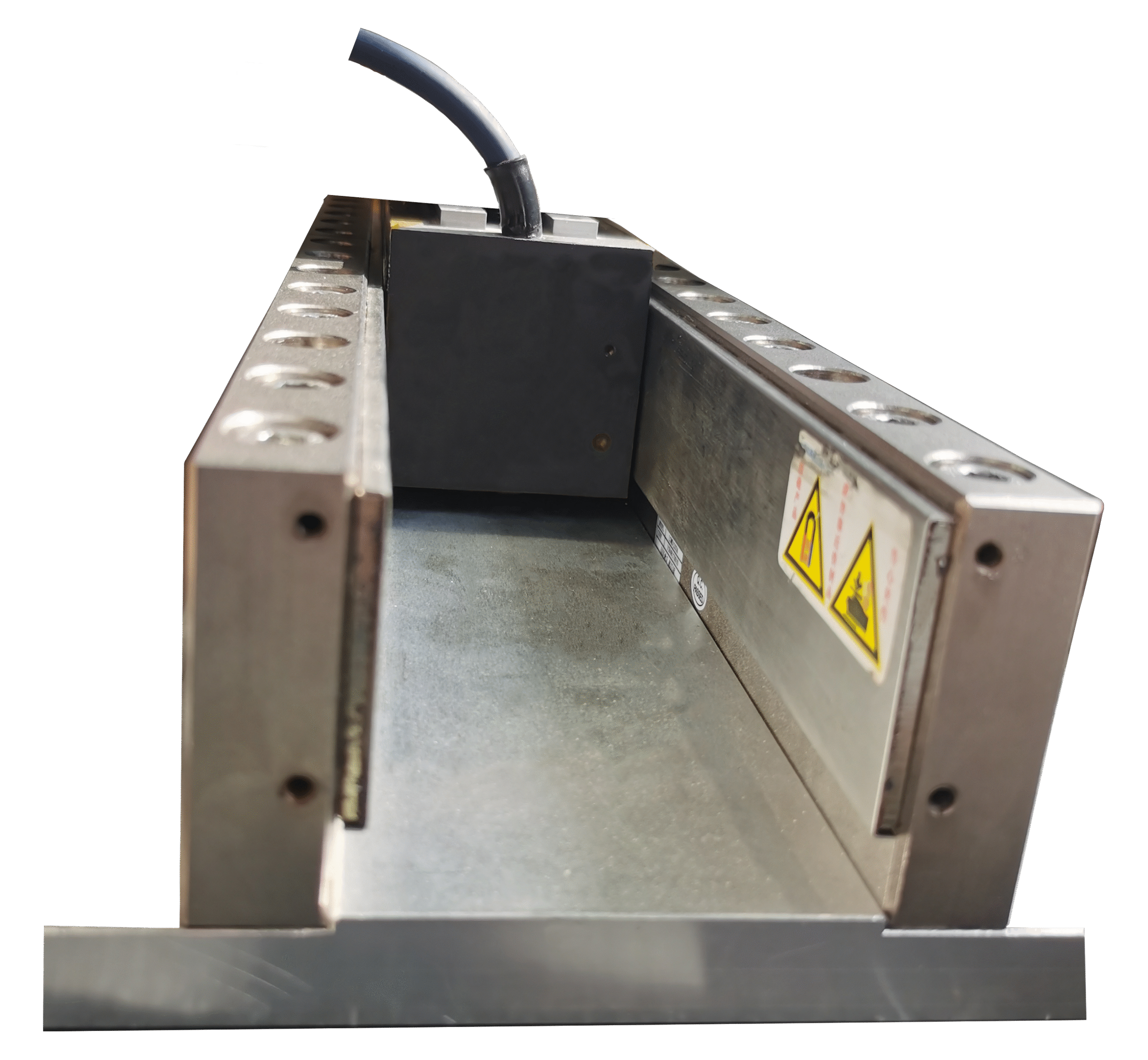

Zero-Cogging Ironless Linear Motor

The LSMU series ironless linear motor guarantees zero cogging and ultra-smooth motion with a non-contact design. It provides high precision and low maintenance, suitable for advanced motion systems across various industries. The motor enhances positioning accuracy while reducing mechanical wear. Its innovative construction optimizes thermal management and durability.

Brand:

Order(MOQ):

1

Product Detail

IRONLESS LINEAR MOTORS WITH ZERO COGGING

HAN’S MOTOR is a full subsidiary of HAN’S LASER GROUP, has been established on the market as a linear motor manufacturer for almost 20 years. With numbers of invent patent technology and won many national high-tech awards. Innovative strength, quality and technical support and service are the guiding principles of our partner. Our linear motors offer high force density, high rigidity and do not require any maintenance.

Our ironless linear motors, which are ideally suited for applications with extreme synchronization requirements due to their cogging-free behavior. Applications for high-end machine tool, laser cutting, semiconductor technology, healthcare industry and other industry required high precision. The ironless linear motor of the LSMU series are characterized by their compact design and the very good price-performance ratio.

The most important features of the LSMU series ironless linear motors are:

Optimized design for best performance due to high motor constant

Perfect and smooth moving also at low speed due to zero detent force (zero cogging)

High acceleration values

No magnetic attraction

Peak forces from 12N to 5,300N, continuous forces from 3N to 883N

Specifications

| Mover Spec: LSMU510xxxx-x-H-NC-N-D00.5 | 101A-S | 201A-S | 201A- P | 301A-S | 301A- P | 402A-S | 402A- P | 108A-S | 501A- S | 501A- P | 601A-P | 601A- P | ||

| Performance Parameters | Symbol | Unit | Series | Series | Parallel | Series | Parallel | Series | Parallel | Series | Series | Parallel | Series | Parallel |

| Continuous Force (Tmax) | Fc | N | 56 | 112 | 112 | 168 | 168 | 224 | 224 | 249 | 280 | 280 | 336 | 336 |

| Peak Force | Fp | N | 317 | 624 | 624 | 936 | 936 | 1248 | 1248 | 1387 | 1560 | 1560 | 1872 | 1872 |

| Motor Constant | Km25 | N//Sqrt (W) | 10.2 | 14.4 | 14.4 | 17.7 | 17.8 | 20.5 | 20.4 | 21.6 | 22.9 | 22.9 | 24.9 | 25.2 |

| Max.Continuous Power Dissipation | Pc | W | 41.4 | 82.8 | 82.8 | 124.2 | 122.0 | 163.4 | 165.6 | 181.9 | 204.8 | 204.8 | 250.6 | 244.0 |

| Continuous Current (Tmax) | Ic | Arms | 2.3 | 2.3 | 4.6 | 2.3 | 4.6 | 2.3 | 4.6 | 2.3 | 2.3 | 4.6 | 2.3 | 4.6 |

| Peak Current (1S) | Ip | Arms | 13.0 | 13.0 | 26.0 | 13.0 | 26.0 | 13.0 | 26.0 | 9.2 | 13.0 | 26.0 | 13.0 | 26.0 |

| Force Constant (25℃,±5%) | Kf | N/Arms | 24.4 | 48.7 | 24.4 | 73.0 | 36.5 | 96.0 | 48.0 | 108.0 | 120.0 | 60.0 | 144.0 | 72.0 |

| Back EMF Constant (25℃,±5%) | Ke | Vrm/rad /s | 8.1 | 16.2 | 8.1 | 24.3 | 12.2 | 32.0 | 16.0 | 36.0 | 40.0 | 20.0 | 48.0 | 24.0 |

| Electrical Resistance (25℃,±5%)P-P | R | Ω | 3.8 | 7.6 | 1.9 | 11.4 | 2.8 | 15.0 | 3.8 | 16.7 | 18.8 | 4.7 | 23.0 | 5.6 |

| Inductance (25℃,±20%)P-P | L | mH | 3.6 | 7.0 | 1.8 | 9.5 | 2.6 | 14.0 | 3.5 | 17.2 | 17.5 | 4.4 | 21.0 | 5.3 |

| Max Coil Temperature | Tmax | ℃ | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

| Polar Distance (N-N) (360℃ Electrical cycle) | 2τ | mm | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Magnetic Attraction | Fa | kN | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Max.DC Bus Voltage | Ubus | V | 330 | 330 | 330 | 330 | 330 | 330 | 330 | 330 | 330 | 330 | 330 | 330 |

| Vmax,Fc@Vbus=310Vdc | Vmax,Fc | m/s | 14.6 | 6.9 | 14.6 | 4.4 | 9.5 | 3.1 | 7.0 | 2.7 | 2.3 | 5.5 | 1.8 | 4.4 |

| Vmax,Fp@Vbus=310Vdc | Vmax,Fp | m/s | 10.8 | 3.4 | 10.8 | 0.8 | 5.9 | 0.0 | 3.4 | 0.4 | 0.0 | 1.9 | 0.0 | 0.9 |

| Vmax,0@Vbus=310Vdc | Vmax,0 | m/s | 15.4 | 7.7 | 15.4 | 5.1 | 10.3 | 3.9 | 7.8 | 3.4 | 3.1 | 6.2 | 2.6 | 5.2 |

| Mover Mass | Mp | Kg | 0.4 | 0.7 | 0.7 | 1.0 | 1.0 | 1.3 | 1.3 | 1.3 | 1.7 | 1.7 | 2.0 | 2.0 |

| Stator Mass within unit length | Ms | Kg/m | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 |

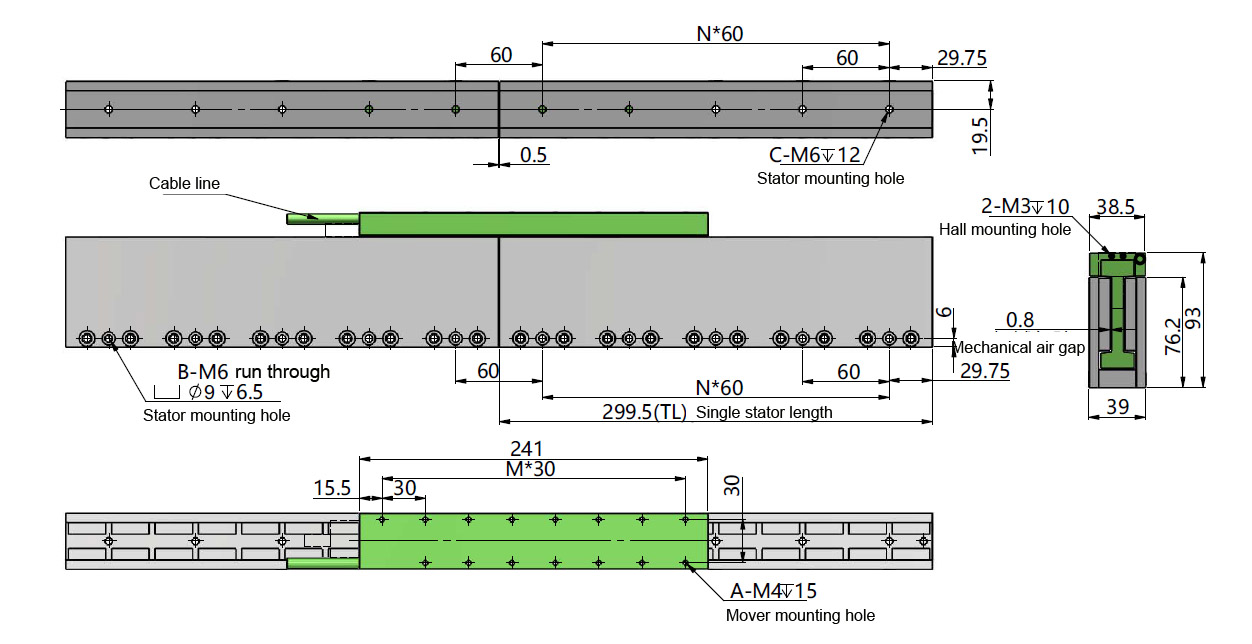

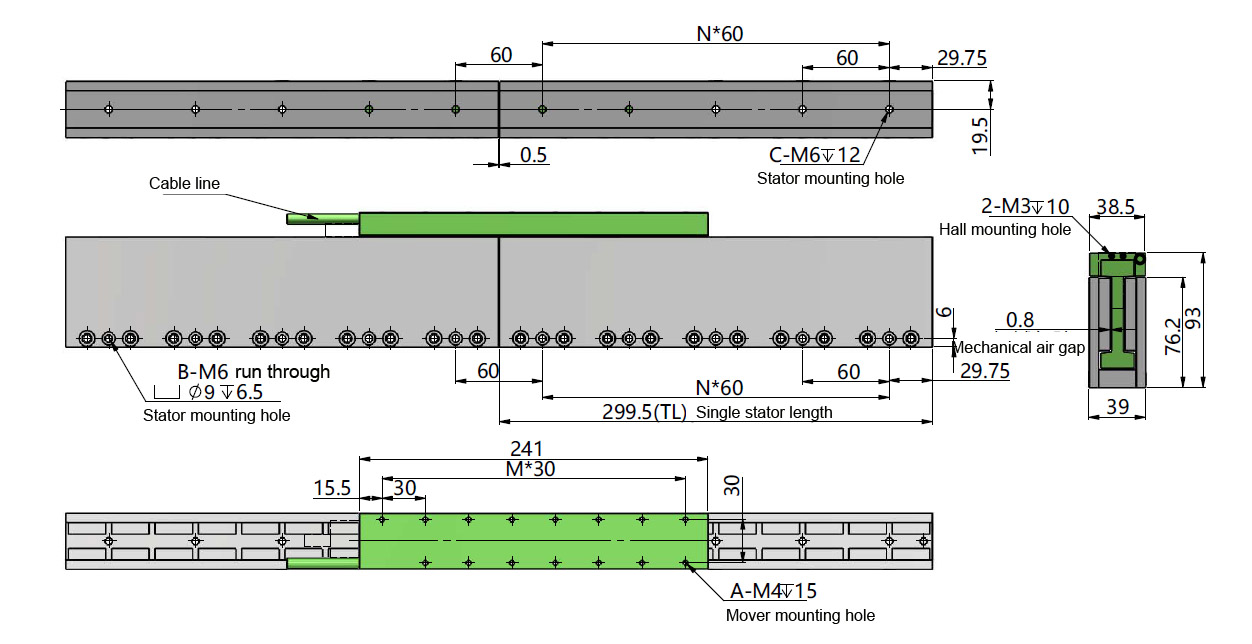

Dimension

| Mover Length | |||

| Mover model | Mover length L | M | Mover mounting hole A |

| LSMU510101A-S-H-NC-N-D00.5 | 61 | 1 | 3 |

| LSMU510201A-S-H-NC-N-D00.5 | 121 | 3 | 7 |

| LSMU510201A-P-H-NC-N-D00.5 | 7 | ||

| LSMU510301A-S-H-NC-N-D00.5 | 181 | 5 | 11 |

| LSMU510301A-P-H-NC-N-D00.5 | 11 | ||

| LSMU510402A-S-H-NC-N-D00.5 | 241 | 7 | 15 |

| LSMU510402A-P-H-NC-N-D00.5 | 15 | ||

| LSMU510501A-S-H-NC-N-D00.5 | 301 | 9 | 19 |

| LSMU510501A-P-H-NC-N-D00.5 | 19 | ||

| LSMU510601A-S-H-NC-N-D00.5 | 361 | 11 | 23 |

| LSMU510601A-P-H-NC-N-D00.5 | 23 | ||

Remark: 1. standard cable length is 0.5m with D-type aviation plug, maximum outer diameter of cable is 7.0mm, minimum bending radius of fixed laying is 3*d, minimum bending radius of dragging chain movement is 5*d, cable length and terminal can be customized.

2. optional temperature sensor.

| Stator Length | ||||

| Stator model | Stator length TL | N | Stator mounting hole B | Stator mounting hole C |

| LSMU5208A | 239.5 | 4 | 5 | 5 |

| LSMU5209A | 239.5 | 3 | 4 | 4 |

| LSMU5210A | 179.5 | 2 | 3 | 3 |

| LSMU5211A | 119.5 | 1 | 2 | 2 |

Suitable for any mover of this series, stator installation mode can be selected.

HAN’S LASER Group

HAN’S Motor Company

Production Center Show

Packaging & Delivery:

Packaging Details.: plywood packing

Port.: Shenzhen (Sea / Air shipping, TNT, UPS, FedEx and DHL ect.)

Leading time: According to the order quantity, 10 days for the small order and 20 days for the bulk order

Sample

Contact Us

Experience our expert support, tailored solutions, and reliable global delivery.

Related Products

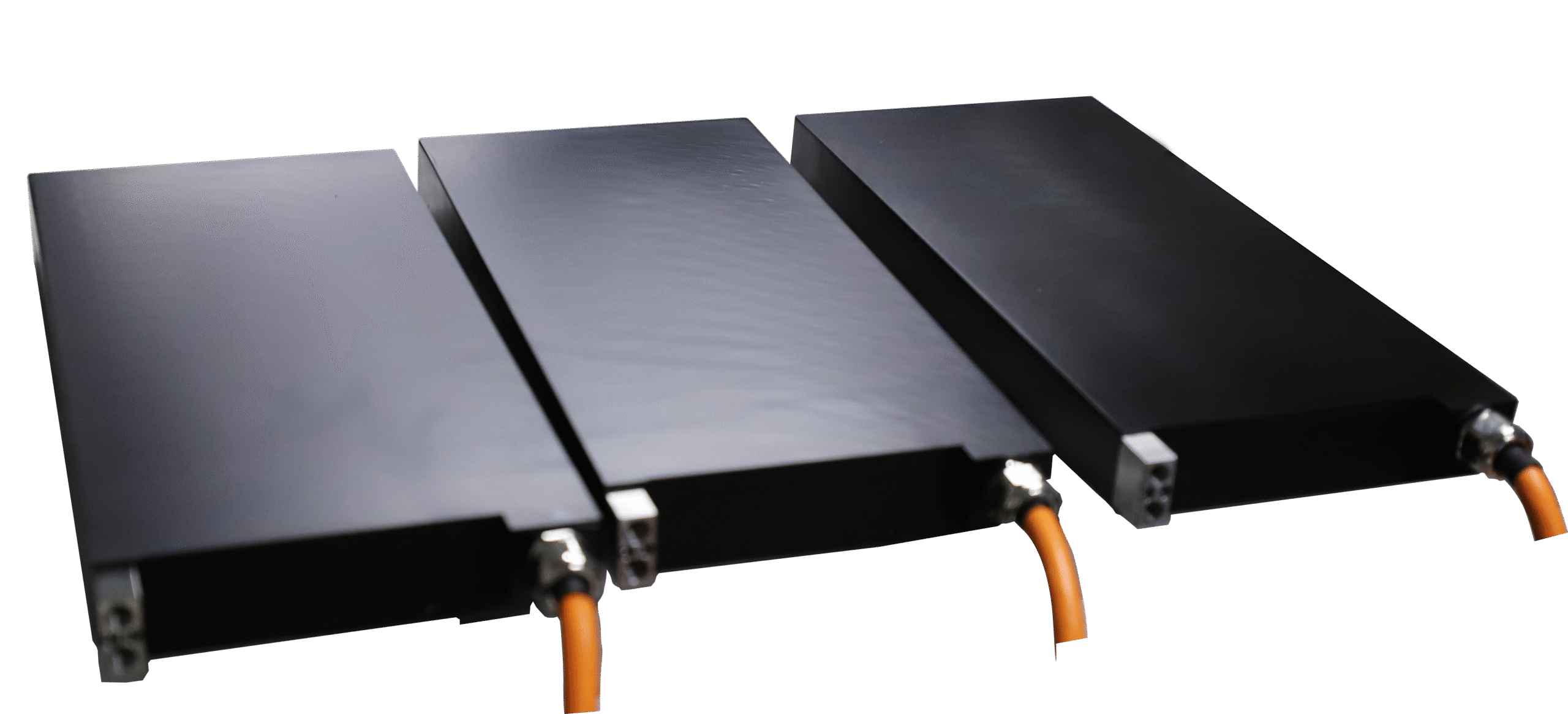

Features

Semiconductor ironless lienar motor is also called carbon fiber board motor with feature high speed, high acceleration, high thrust density and efficient heat dissipation, enabling stable high-performance operation in semiconductor applications.

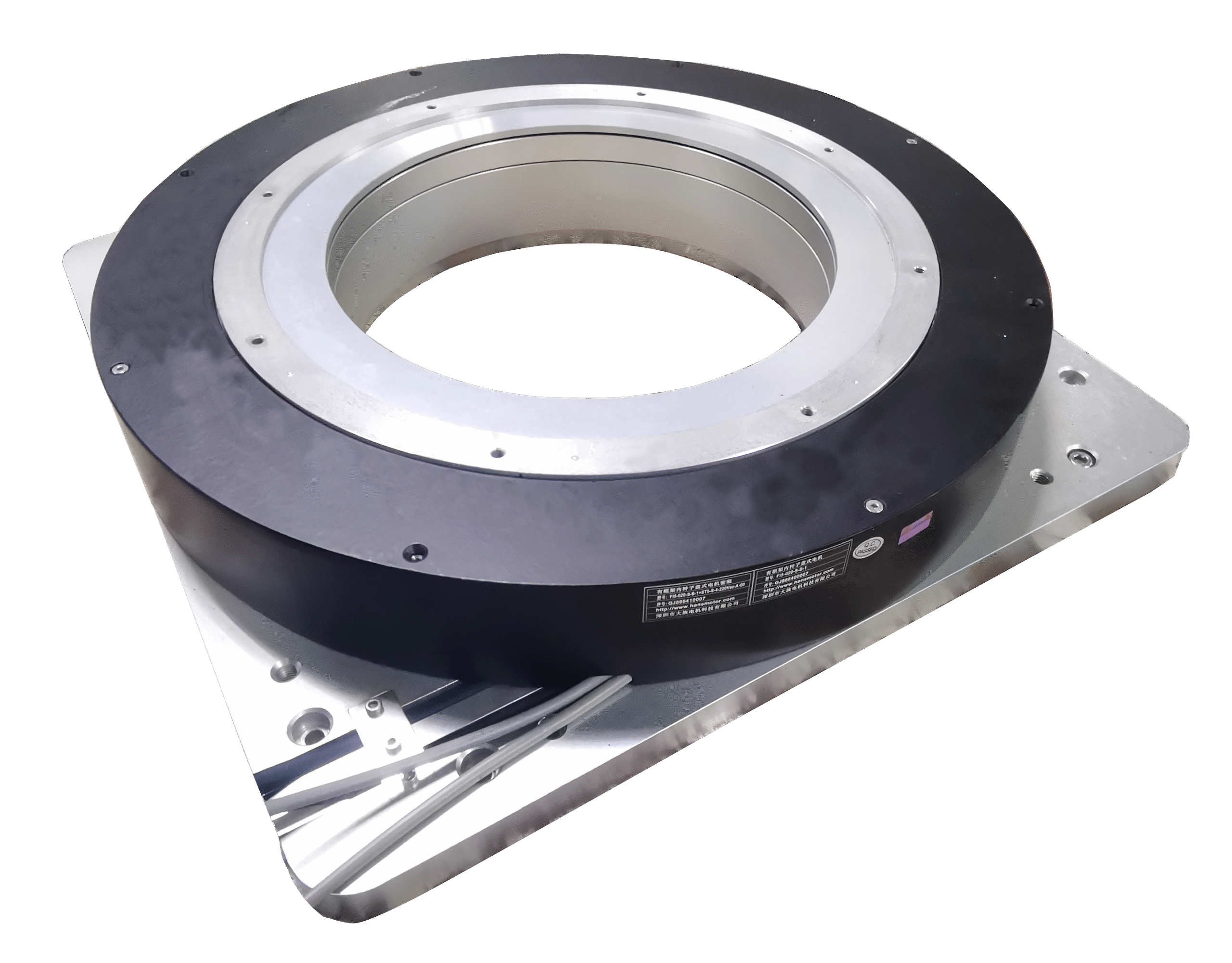

Features

FE3 Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

This linear motor is specially designed for semiconductor packaging equipment, featuring high precision, fast response, and stable performance to meet the demanding requirements of advanced packaging processes.

Features

LSMFK series Water-Cooled Ironcore Linear Motors feature high thrust density 10000Nm and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

LSMD2 series double-sided magnet ironcore linear motor adopt gas cooling technology, high thrust with superior acceleration, cogging torque reduction technology, built-in thermal protection, and cancellation of unbalanced electromagnetic forces in demanding applications.