Products

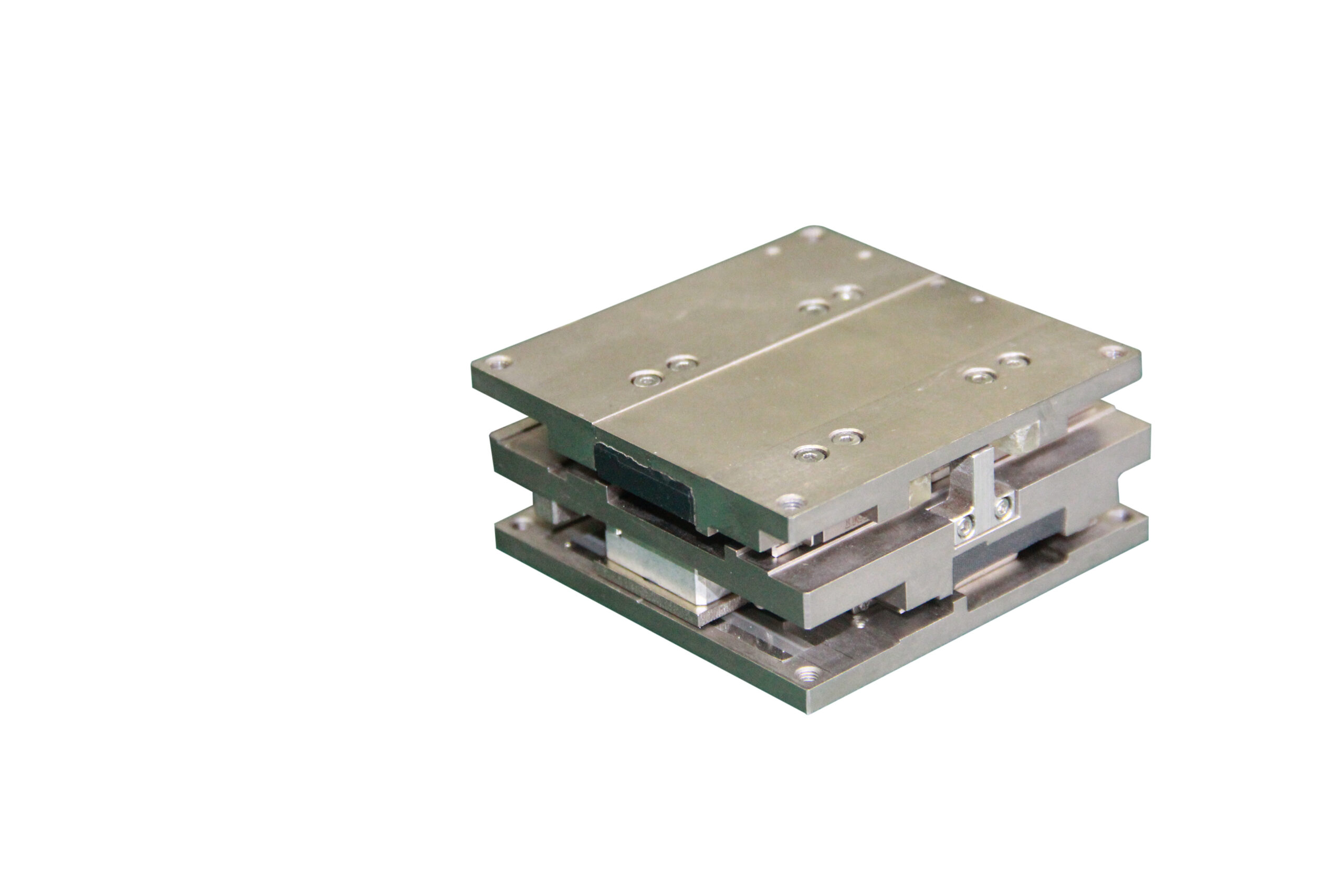

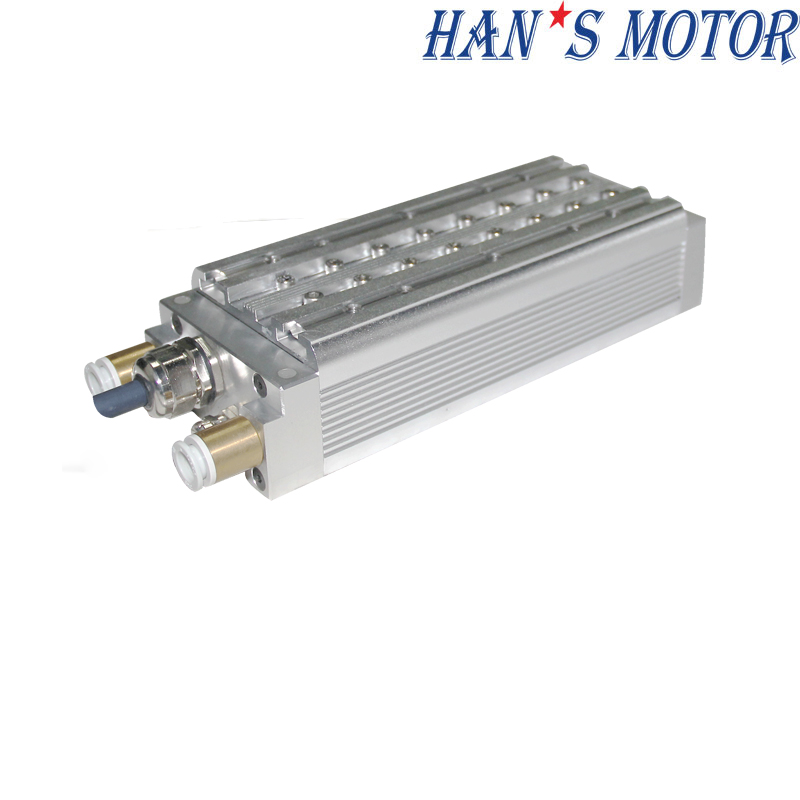

Linear Motor Stage System

This stage system is optimized for precise positioning and smooth trajectory control. It combines a linear motor with high-resolution feedback for responsive performance. The robust design reduces vibration and improves consistency. It’s adaptable for various automation tasks requiring accurate multi-axis movement. Excellent for metrology, inspection, or precision manufacturing.

Brand:

Order(MOQ):

1

Product Detail

Characteristics:

• The warranty period is 12 months

• Production capacity 10000 Pieces per month

• CE, RoHS and UL certification

• Free product manual and 3D model and a competitive price can be provided

• Module several types: miniature stages,single axis stages, general linear motor stages, multi-axis stages, gantry stages, extra large marble stages, servo motor stages

Product Specifications

Motor Model/Parameter

| Ironless Linear Motor | Iron Core Linear Motor | ||||||||||||

| Parameter\ Motor Model | Unit | U53 | U54 | U55 | U56 | FJ22 | FJ23 | FL22 | FL32 | FL42 | FL23 | FL33 | FL43 |

| Continuous Force (Tmax) | N | 168 | 224 | 280 | 336 | 208 | 332 | 196 | 294 | 392 | 314 | 472 | 629 |

| Peak Force | N | 936 | 1248 | 1560 | 1872 | 831 | 1329 | 517 | 776 | 1035 | 827 | 1237 | 1653 |

| Motor Constant | N//SqrtW | 15 | 17.4 | 19.4 | 21.3 | 27.5 | 24.4 | 18.9 | 23.4 | 27.2 | 25.3 | 31 | 36.2 |

| Max.Continuous Power Dissipation | W | 125 | 166.6 | 208.3 | 250 | 57.1 | 184.8 | 107.5 | 157.9 | 208.3 | 154.6 | 231.8 | 302.4 |

| Continuous Current (Tmax) | Arms | 2.3 | 2.3 | 2.3 | 2.3 | 2.2 | 4.4 | 4 | 4 | 4 | 4 | 4 | 4 |

| Peak Current (1S) | Arms | 13 | 13 | 13 | 13 | 9 | 18 | 12 | 12 | 12 | 12 | 12 | 12 |

| Force Constant (25℃,±5%) | N/Arms | 73 | 96 | 120 | 144 | 94.8 | 75.6 | 49 | 73.5 | 98 | 78.5 | 118 | 157 |

| Back EMF Constant (25℃,±5%) | Vrms/rad/s | 24.3 | 32 | 40 | 48 | 31.6 | 25.2 | 16.3 | 24.5 | 32.7 | 26 | 39.3 | 52.4 |

| Electrical Resistance(25℃,±5%)P-P | Ω | 11.25 | 15 | 18.75 | 22.5 | 11.8 | 4.5 | 3.2 | 4.7 | 6.2 | 4.6 | 6.9 | 9 |

| Inductance(25℃,±20%)P-P | mH | 10.5 | 14 | 17.5 | 21 | 40 | 15.3 | 15 | 22.5 | 30 | 24 | 36 | 48 |

| Max Coil Temperature | ℃ | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

| Polar Distance (N-N) (360℃ Electrical cycle) | mm | 60 | 60 | 60 | 60 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Magnetic Attraction | KN | 0 | 0 | 0 | 0 | 1.23 | 1.82 | 1.1 | 1.6 | 2.1 | 1.7 | 2.6 | 3.4 |

| Mover Mass | Kg | 1 | 1.3 | 1.65 | 2 | 1.7 | 2.4 | 2.5 | 3.7 | 4.9 | 3.8 | 5.5 | 7.3 |

Linear Motor Stages Selection

| LMP230-U53-xxx-xxx-A | ||||||||||||

| Parameter\ Stroke (mm) | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 10 | 14 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 |

| N | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 |

| Stage Total Length (mm) | 420 | 520 | 620 | 720 | 820 | 920 | 1020 | 1120 | 1220 | 1320 | 1420 | 1520 |

| Dowel Pin D1 (mm) | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

| Stage Weight (kg) | 23 | 27 | 31 | 35 | 39 | 43 | 47 | 51 | 55 | 59 | 63 | 67 |

| Sliding Table M (mm) | 250 | |||||||||||

| A | 8 | |||||||||||

| B | 1 | |||||||||||

| Motion Parts Weight (kg) | 7 | |||||||||||

| LMP230-U54-xxx-xxx-A | ||||||||||||

| Parameter\ Stroke (mm) | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 14 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 | 34 |

| N | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 |

| Stage Total Length (mm) | 470 | 570 | 670 | 770 | 870 | 970 | 1070 | 1170 | 1270 | 1370 | 1470 | 1570 |

| Dowel Pin D1 (mm) | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

| Stage Weight (kg) | 26 | 30 | 34 | 38 | 42 | 46 | 50 | 54 | 58 | 62 | 66 | 70.0 |

| Sliding Table M (mm) | 300 | |||||||||||

| A | 16 | |||||||||||

| B | 2 | |||||||||||

| Motion Parts Weight (kg) | 8.5 | |||||||||||

| LMP230-U55-xxx-xxx-A | ||||||||||||

| Parameter\ Stroke (mm) | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 10 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 | 34 |

| N | 1 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 |

| Stage Total Length (mm) | 390 | 630 | 730 | 830 | 930 | 1030 | 1130 | 1230 | 1330 | 1430 | 1530 | 1630 |

| Dowel Pin D1 (mm) | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

| Stage Weight (kg) | 11.5 | 34 | 38 | 42 | 46 | 50 | 54 | 58 | 62 | 66 | 70 | 74.0 |

| Sliding Table M (mm) | 360 | |||||||||||

| A | 16 | |||||||||||

| B | 2 | |||||||||||

| Motion Parts Weight (kg) | 10 | |||||||||||

| LMP230-U56-xxx-xxx-A | ||||||||||||

| Parameter\ Stroke (mm) | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 | 34 | 38 |

| N | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 | 8 |

| Stage Total Length (mm) | 590 | 690 | 790 | 890 | 990 | 1090 | 1190 | 1290 | 1390 | 1490 | 1590 | 1690 |

| Dowel Pin D1 (mm) | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

| Stage Weight (kg) | 34 | 38 | 42 | 46 | 50 | 54 | 58 | 62 | 66 | 70 | 74 | 78.0 |

| Sliding Table M (mm) | 420 | |||||||||||

| A | 24 | |||||||||||

| B | 3 | |||||||||||

| Motion Parts Weight (kg) | 3.8 | |||||||||||

| LMP230-FJ22-xxx-xxx-A | ||||||||||||

| Parameter\ Stroke (mm) | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 10 | 14 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 |

| N | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 |

| Stage Total Length (mm) | 420 | 520 | 620 | 720 | 820 | 920 | 1020 | 1120 | 1220 | 1320 | 1420 | 1520 |

| Dowel Pin D1 (mm) | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

| Stage Weight (kg) | 22.4 | 25.6 | 28.8 | 32 | 35.2 | 38.4 | 41.6 | 44.8 | 48 | 51.2 | 54.4 | 57.6 |

| Sliding Table M (mm) | 280 | |||||||||||

| A | 8 | |||||||||||

| B | 1 | |||||||||||

| Motion Parts Weight (kg) | 9 | |||||||||||

| LMP230-FJ23-xxx-xxx-A | ||||||||||||

| Parameter\ Stroke (mm) | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 14 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 | 34 |

| N | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 |

| Stage Total Length (mm) | 450 | 550 | 650 | 750 | 850 | 950 | 1050 | 1150 | 1250 | 1350 | 1450 | 1550 |

| Dowel Pin D1 (mm) | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

| Stage Weight (kg) | 24.6 | 27.8 | 31 | 34.2 | 37.4 | 40.6 | 43.8 | 47 | 50.2 | 53.4 | 56.6 | 59.8 |

| Sliding Table M (mm) | 280 | |||||||||||

| A | 8 | |||||||||||

| B | 1 | |||||||||||

| Motion Parts Weight (kg) | 10.4 | |||||||||||

| LMP230-FL22-xxx-xxx-A | ||||||||||||

| Parameter\ Stroke (mm) | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 14 | 14 | 18 | 18 | 22 | 22 | 26 | 26 | 30 | 30 | 34 | 34 |

| N | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | 6 | 7 | 7 |

| Stage Total Length (mm) | 510 | 610 | 710 | 810 | 910 | 1010 | 1110 | 1210 | 1310 | 1410 | 1510 | 1610 |

| Dowel Pin D1 (mm) | 50 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 |

| Stage Weight (kg) | 29.1 | 32.3 | 35.5 | 38.7 | 41.9 | 45.1 | 48.3 | 51.5 | 54.7 | 57.9 | 61.1 | 64.3 |

| Sliding Table M (mm) | 340 | |||||||||||

| A | 16 | |||||||||||

| B | 2 | |||||||||||

| Motion Parts Weight (kg) | 13.2 | |||||||||||

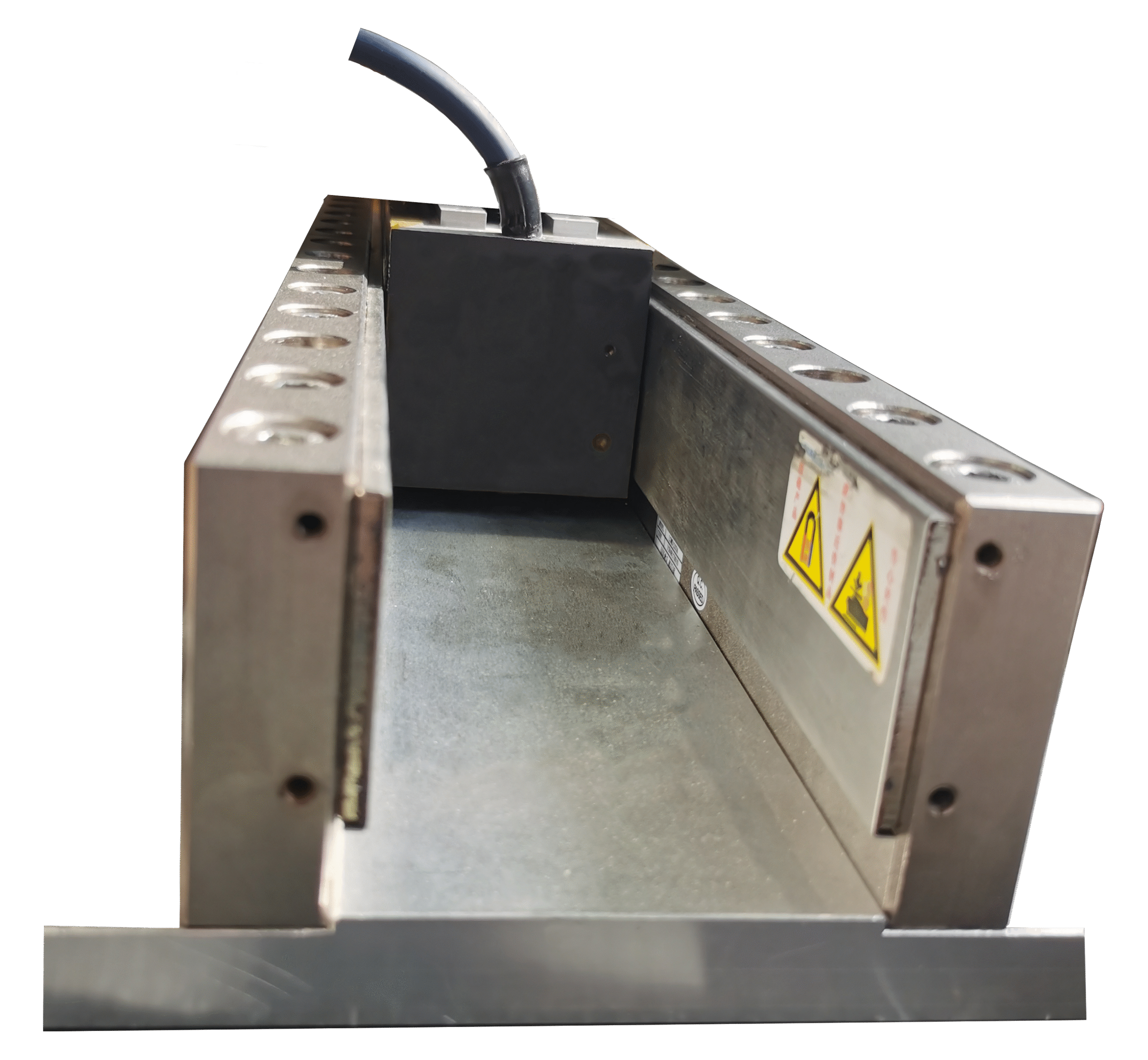

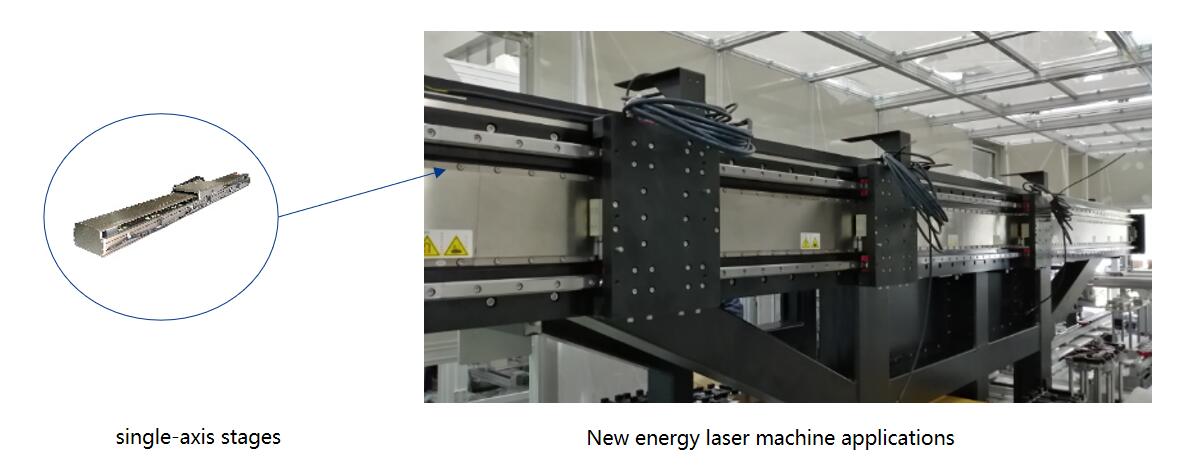

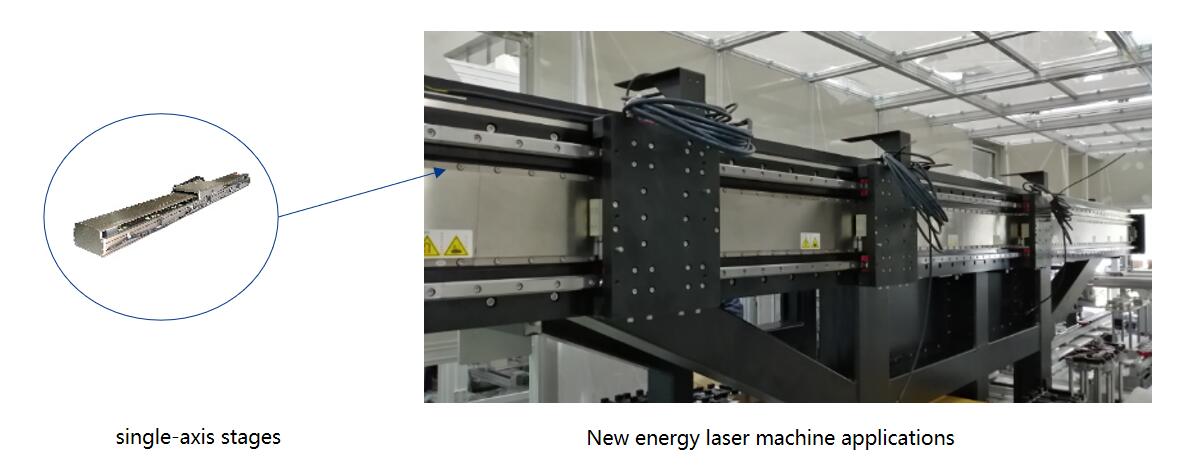

Industry Applications:

Long stroke, high speed, high response single-axis motor modules which apply to laser welding machine, laser cutting machine, laser marking machine, carbon dioxide(CO₂) , light sorce applications.

Packaging & Delivery:

Packaging Details.: plywood packing/Cantainer

Port.: Shenzhen ( BY SEA, AIR,TNT, UPS, FedEx and DHL ect.)

Leading time: According to the order quantity, 15-20 days for trial order and 30-45 days for bulk order

Sample

Contact Us

Experience our expert support, tailored solutions, and reliable global delivery.

Related Products

Features

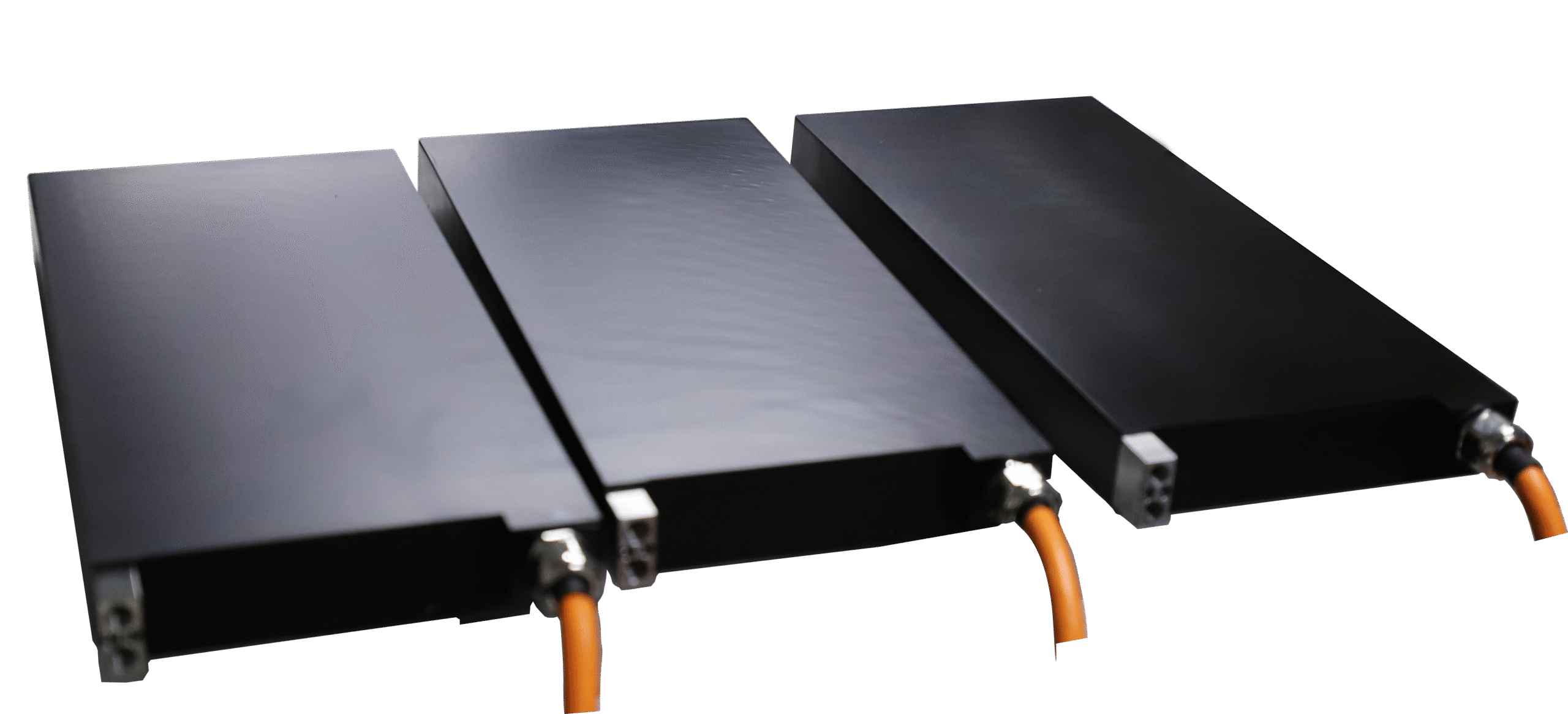

Semiconductor ironless lienar motor is also called carbon fiber board motor with feature high speed, high acceleration, high thrust density and efficient heat dissipation, enabling stable high-performance operation in semiconductor applications.

Features

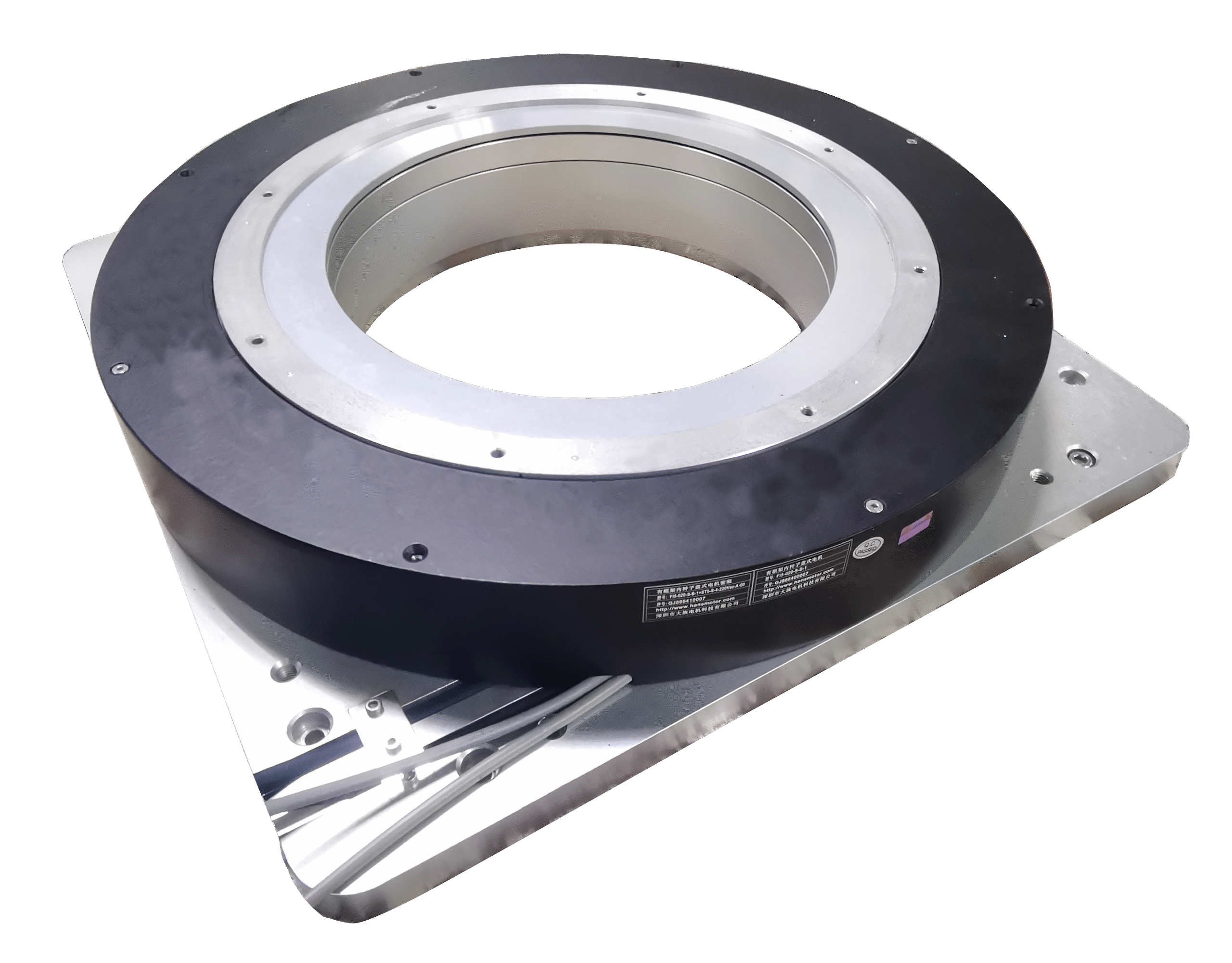

FE3 Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

This linear motor is specially designed for semiconductor packaging equipment, featuring high precision, fast response, and stable performance to meet the demanding requirements of advanced packaging processes.

Features

LSMFK series Water-Cooled Ironcore Linear Motors feature high thrust density 10000Nm and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

LSMD2 series double-sided magnet ironcore linear motor adopt gas cooling technology, high thrust with superior acceleration, cogging torque reduction technology, built-in thermal protection, and cancellation of unbalanced electromagnetic forces in demanding applications.