Products

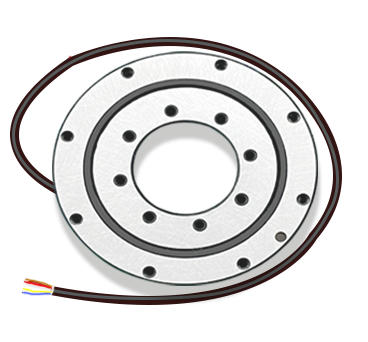

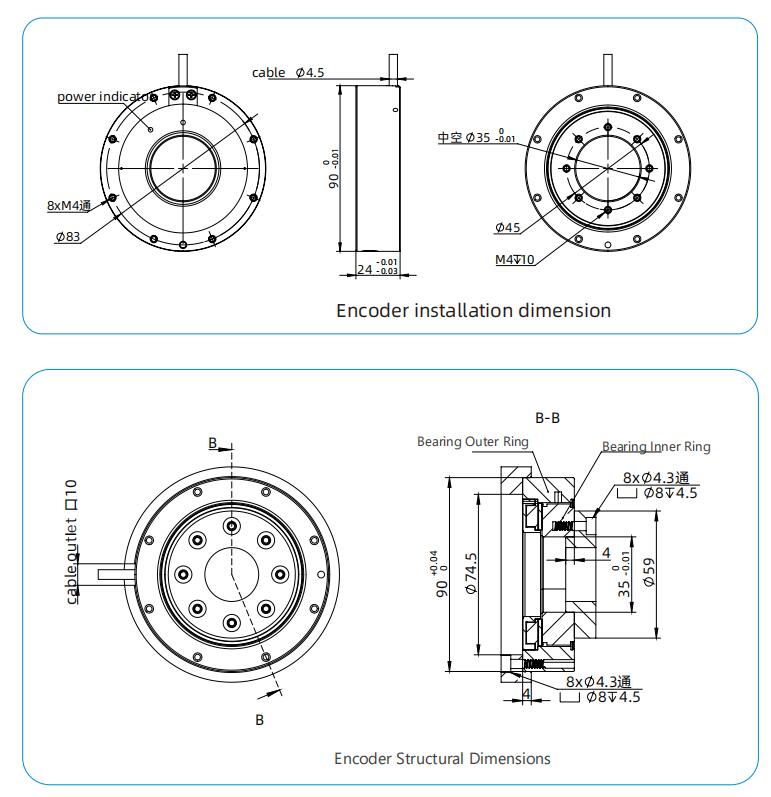

Integrated Time-Grating Angular Encoder

The Integrated Time-Grating Angular Encoder provides high-resolution, high-accuracy, and high-speed absolute angle measurement. Its robust, oil- and shock-resistant design ensures reliable operation in harsh industrial environments. Easy to install, it is ideal for robotics, CNC machines, aerospace, and precision motion control systems requiring precise position detection.

Brand:

Order(MOQ):

1

Product Detail

Feature:

1.High Precision

Achieves ultra-accurate displacement and angle measurement with multiple accuracy options: ±40″ to ±1″. Ideal for robotics, CNC machines, and aerospace applications.

2.High Speed Performance

Maintains high-resolution output even at fast rotational speeds, supporting up to 7000 rpm with 2²³/turn resolution. Perfect for real-time motion control systems.

3.Ultra-High Resolution

Delivers exceptional signal quality with strong EMI resistance and fine subdivisions: from 2¹¹/turn (0.0027466°) to 2²³/turn (0.000043°). Suitable for precision engineering and industrial automation.

4.Fast Response Time

Provides ultra-low latency feedback—measurement signals within hundreds of nanoseconds and position calculations in 5–10 μs. Ensures immediate reaction for high-speed equipment.

Highlights:

· High-Precision Angular Measurement – Achieves ultra-accurate absolute angle positioning from ±40″ to ±1″ for robotics, CNC, and industrial automation.

· High-Speed Performance – Maintains high-resolution output even at speeds up to 7000 rpm.

· Ultra-High Resolution – Fine subdivisions from 2¹¹/turn (0.0027466°) to 2²³/turn (0.000043°) with strong EMI resistance.

· Fast Response Time – Measurement signals in hundreds of nanoseconds; position calculations in 5–10 μs for real-time motion control.

· Rugged & Reliable Design – Oil-resistant, shockproof, vibration-resistant, and easy to install for harsh industrial environments.

Application:

Time grating encoders provide high resolution, high accuracy, high repeatability, and fast-response absolute position measurement, with compact structure, oil- and dust-resistance, shock- and vibration-proof design, and easy installation. They are widely used in various industries, offering precise real-time position feedback for direct-drive and linear motors, CNC machine tool axes and accessories, automation equipment platforms and actuators, laser processing devices, testing and calibration instruments, as well as robotic joints and manipulators.

Specification

| Specifications/Model | HTRA2-0090A |

| Measuring Range | (Single-turn Absolute) 0-360° |

| Resolution Ratio | 23bit |

| Accuracy | ±8” |

| Repeatability | ±1” |

| Rotational Speed/Limit Speed | ≤270rpm/≤450rpm |

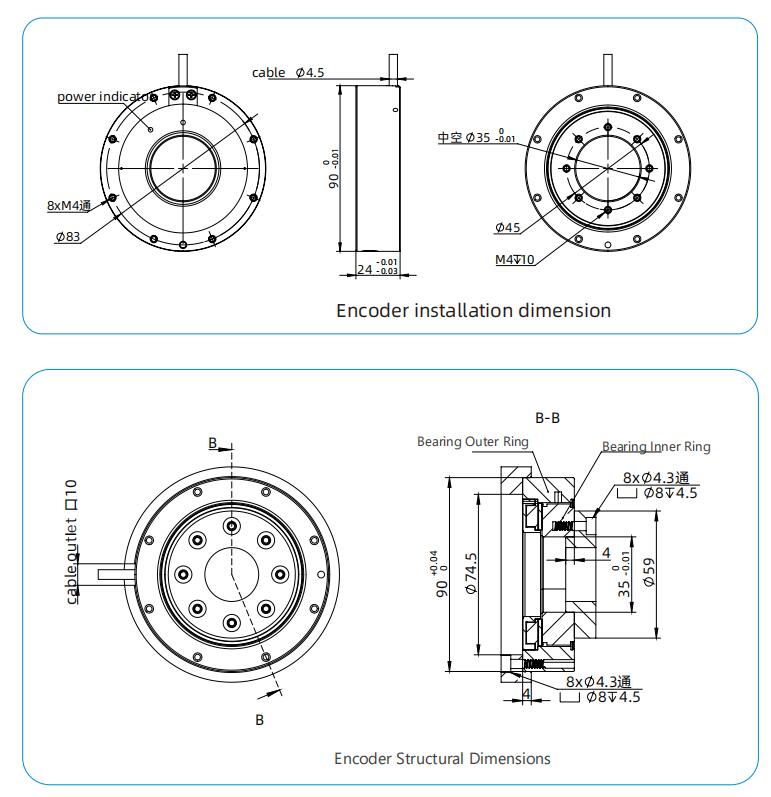

| Encoder (Outer Diameter/Inner Diameter/Thickness) | 90mm/35mm/24mm |

| Operating Voltage | 5V DC±10% |

| Operating Current | ≤200mA |

| Data Format | Natural Binary |

| Rotation Direction | (Default) Viewed from the rotor rear side, clockwise rotation increases the angular data. |

| Communication Type | BISS-C/SSI/UART/ABZ ( Incremental) |

| Communication Speed | BISS-C/SS:(Synchronous Clock) 100K~2.5M UART:9.6K~2.5M |

| Communication Interface | RS422/RS485 |

| Cable Exit Direction | Radial (customizable upon request) |

| Cable Length | 500mm |

| Axial/Radial Clearance Value | -0.01~0mm |

| Dynamic Axial Load/Static Axial Load | Ca-30.7KN/Coa-98.3KN |

| Dynamic Radial Load/ Static Radial Load | Cr-17.5KN/Cor-22.3KN |

| Bearing Hardness | HRC58~63 |

Installation Dimension

Sample

Contact Us

Experience our expert support, tailored solutions, and reliable global delivery.

Related Products

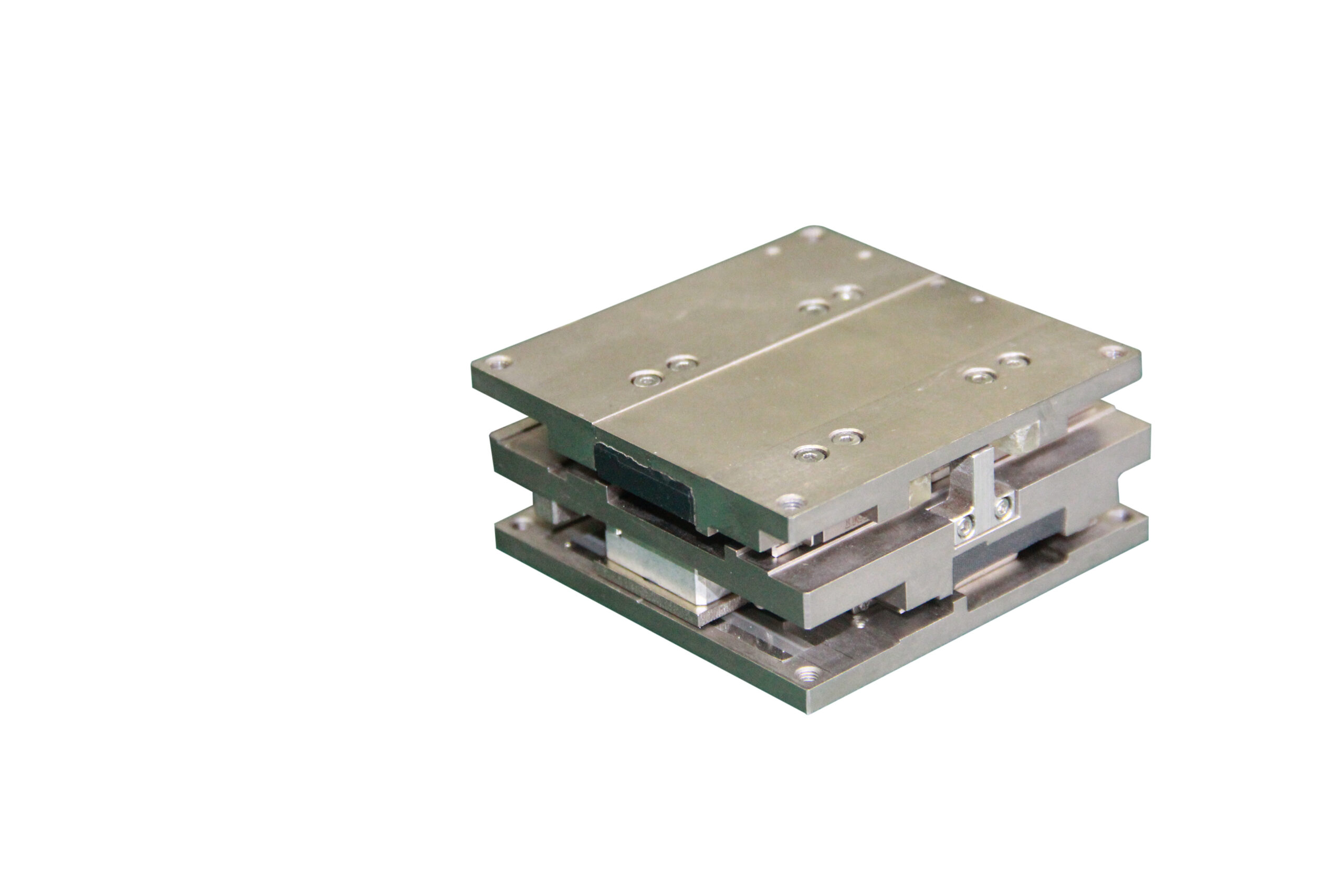

Features

Semiconductor ironless lienar motor is also called carbon fiber board motor with feature high speed, high acceleration, high thrust density and efficient heat dissipation, enabling stable high-performance operation in semiconductor applications.

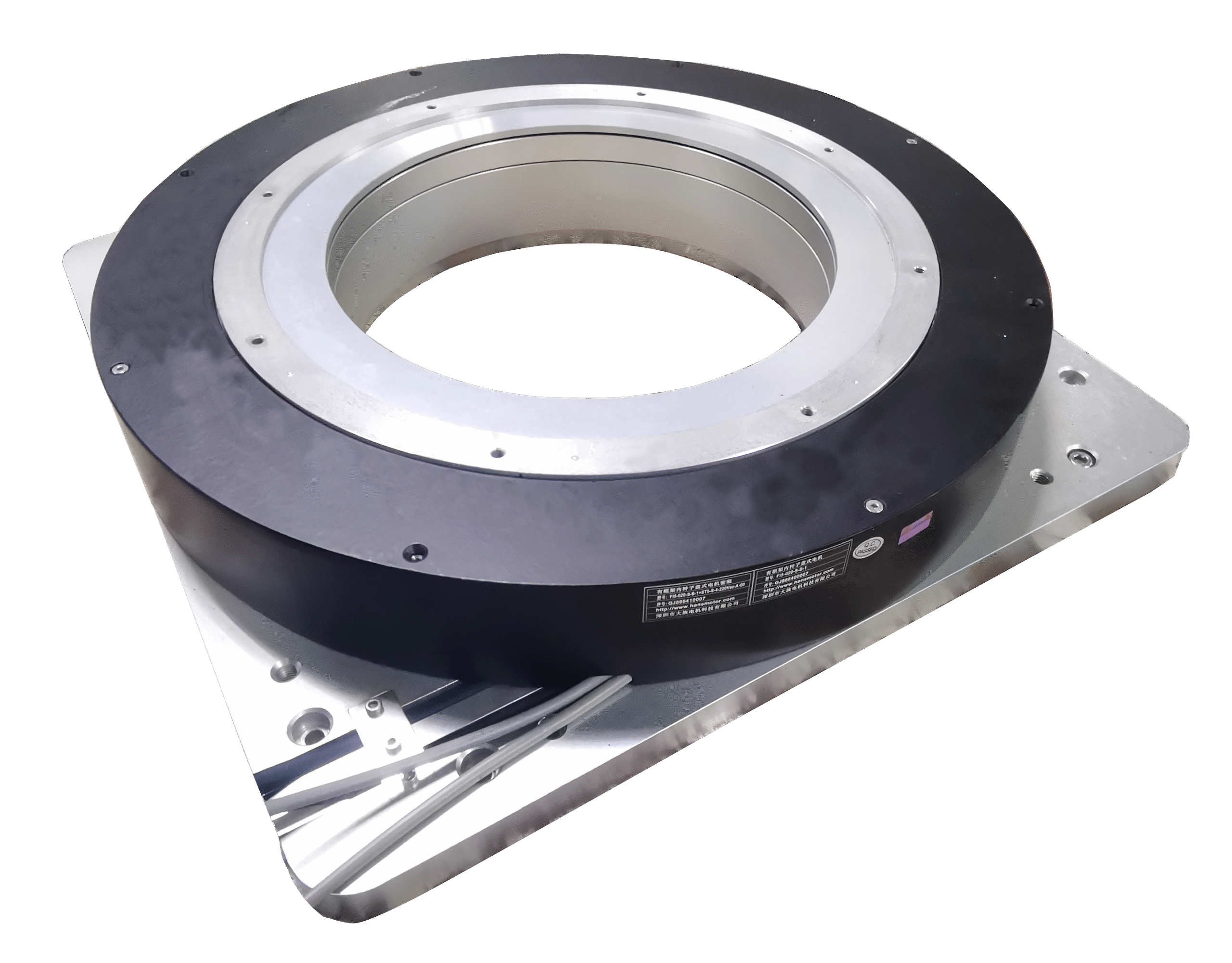

Features

FE3 Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

This linear motor is specially designed for semiconductor packaging equipment, featuring high precision, fast response, and stable performance to meet the demanding requirements of advanced packaging processes.

Features

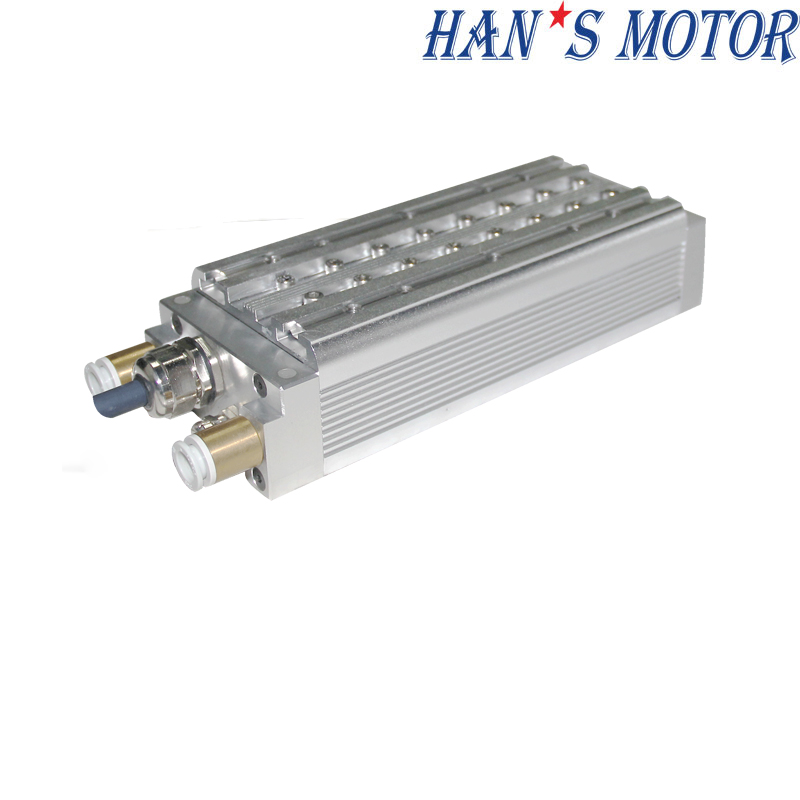

LSMFK series Water-Cooled Ironcore Linear Motors feature high thrust density 10000Nm and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

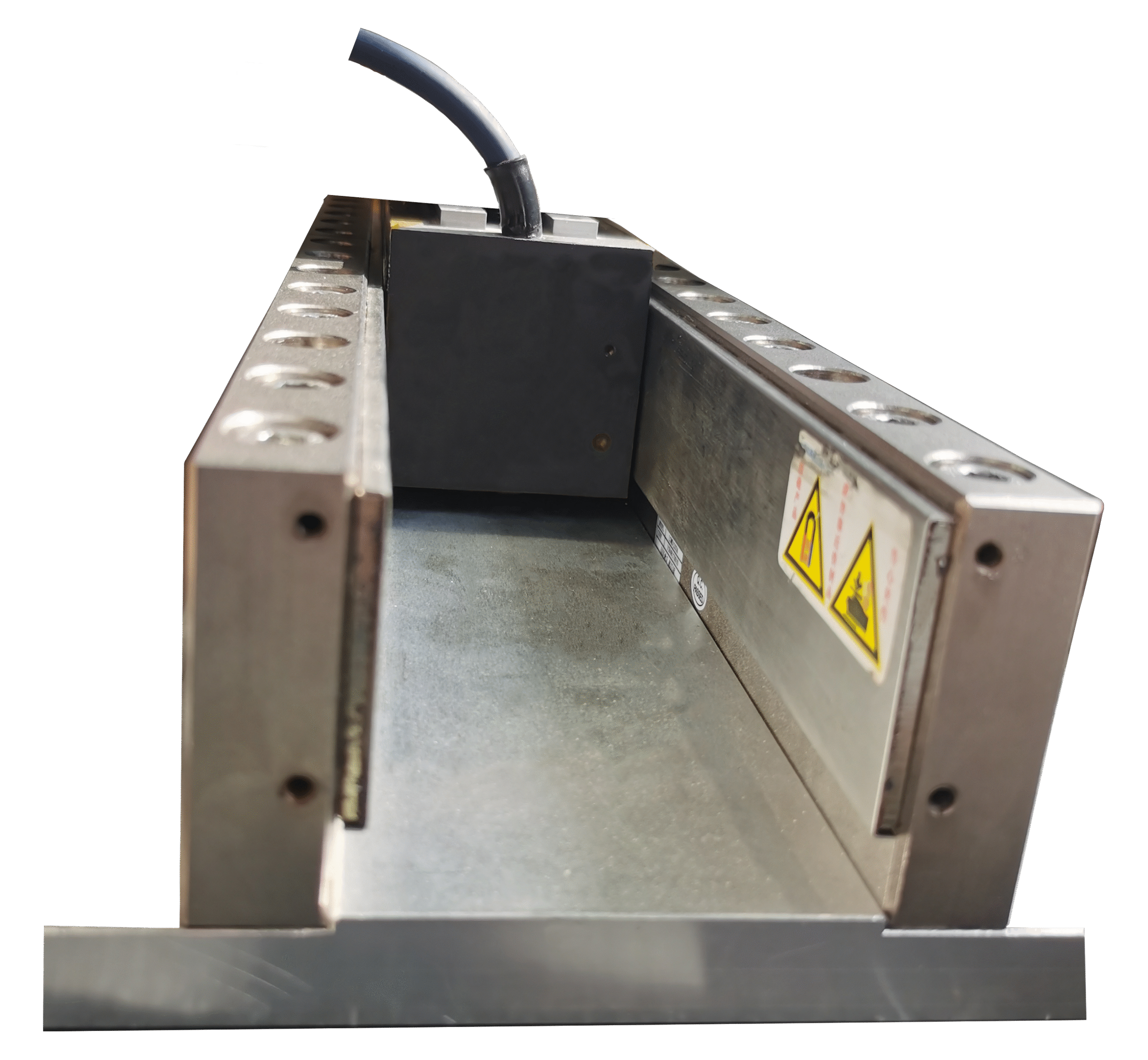

LSMD2 series double-sided magnet ironcore linear motor adopt gas cooling technology, high thrust with superior acceleration, cogging torque reduction technology, built-in thermal protection, and cancellation of unbalanced electromagnetic forces in demanding applications.