Products

Coreless Linear Motor

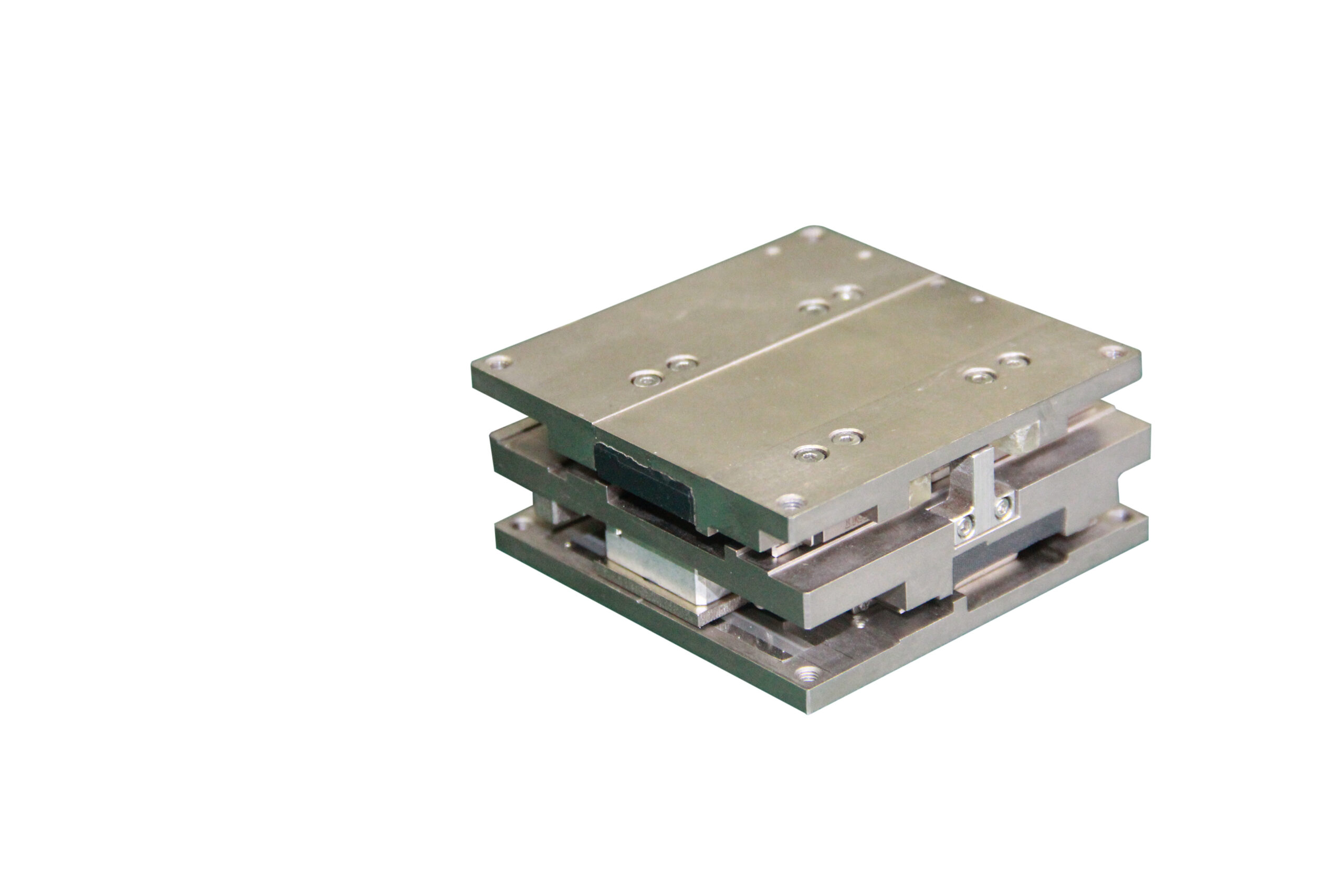

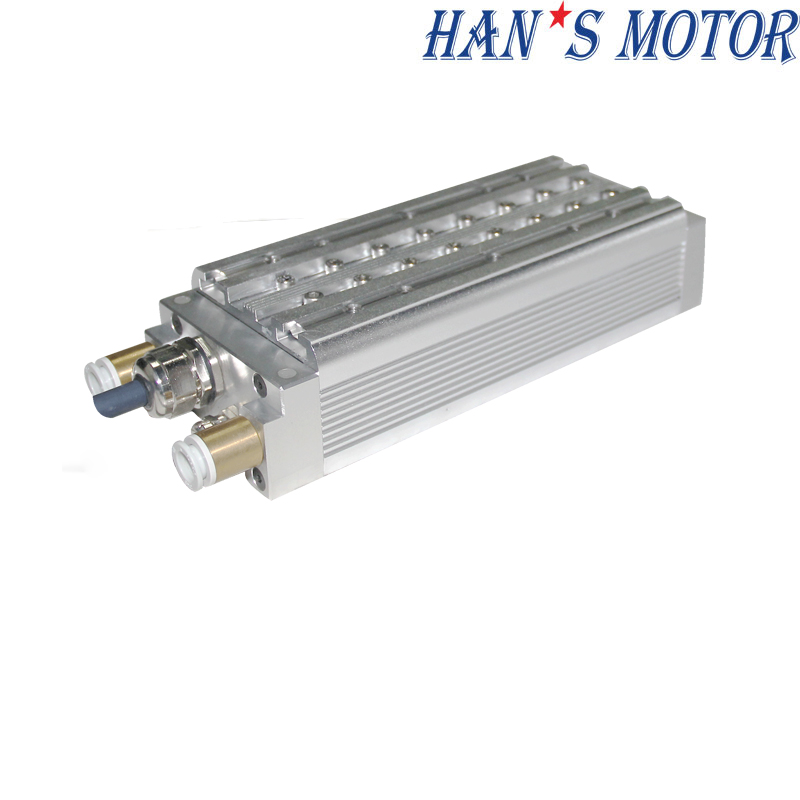

High Torque Coreless Linear Motor LSMU5 is specially designed for high-performance automation equipment. This advanced U-channel structure offers high acceleration and zero cogging, making it ideal for precision applications. With compact size and efficient heat dissipation, it fits robotic and industrial use cases perfectly. Explore how this coreless linear motor enhances your automation solutions.

Brand:

Order(MOQ):

1

Product Detail

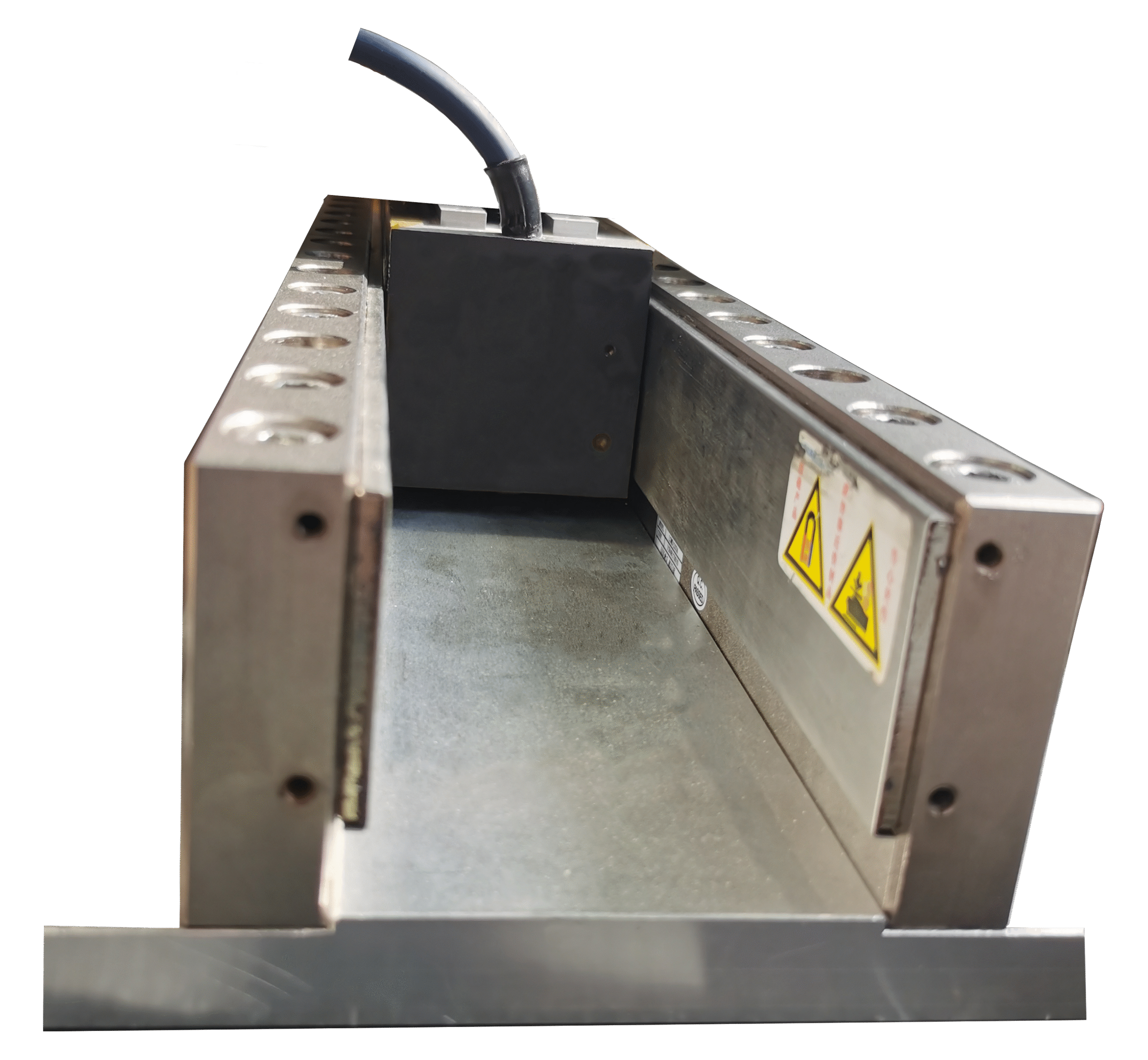

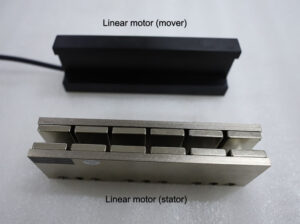

Ironless linear Motor

The encapsulated moving coil assembly moves through a gap in the long “U” shaped magnet assembly. A customer supplied bearing system is required to guide the moving coil assembly and to maintain a .025″ [0.63 mm] clearance between the magnet and the coil assembly. There is no attractive force between the motor coil and the magnet assembly.

Advantages

1. Unlimited stroke length

2. Zero cogging

3. High speed and accelerations of light loads

4. Low moving mass

5. Multiple motors coils inside a single magnet assembly

Specifications

| Mover Spec: LSMU510xxxx-x-H-NC-N-D00.5 | 101A-S | 201A-S | 201A- P | 301A-S | 301A- P | 402A-S | 402A- P | 108A-S | 501A- S | 501A- P | 601A-P | 601A- P | ||

| Performance Parameters | Symbol | Unit | Series | Series | Parallel | Series | Parallel | Series | Parallel | Series | Series | Parallel | Series | Parallel |

| Continuous Force (Tmax) | Fc | N | 56 | 112 | 112 | 168 | 168 | 224 | 224 | 249 | 280 | 280 | 336 | 336 |

| Peak Force | Fp | N | 317 | 624 | 624 | 936 | 936 | 1248 | 1248 | 1387 | 1560 | 1560 | 1872 | 1872 |

| Motor Constant | Km25 | N//Sqrt (W) | 10.2 | 14.4 | 14.4 | 17.7 | 17.8 | 20.5 | 20.4 | 21.6 | 22.9 | 22.9 | 24.9 | 25.2 |

| Max.Continuous Power Dissipation | Pc | W | 41.4 | 82.8 | 82.8 | 124.2 | 122.0 | 163.4 | 165.6 | 181.9 | 204.8 | 204.8 | 250.6 | 244.0 |

| Continuous Current (Tmax) | Ic | Arms | 2.3 | 2.3 | 4.6 | 2.3 | 4.6 | 2.3 | 4.6 | 2.3 | 2.3 | 4.6 | 2.3 | 4.6 |

| Peak Current (1S) | Ip | Arms | 13.0 | 13.0 | 26.0 | 13.0 | 26.0 | 13.0 | 26.0 | 9.2 | 13.0 | 26.0 | 13.0 | 26.0 |

| Force Constant (25℃,±5%) | Kf | N/Arms | 24.4 | 48.7 | 24.4 | 73.0 | 36.5 | 96.0 | 48.0 | 108.0 | 120.0 | 60.0 | 144.0 | 72.0 |

| Back EMF Constant (25℃,±5%) | Ke | Vrm/rad /s | 8.1 | 16.2 | 8.1 | 24.3 | 12.2 | 32.0 | 16.0 | 36.0 | 40.0 | 20.0 | 48.0 | 24.0 |

| Electrical Resistance (25℃,±5%)P-P | R | Ω | 3.8 | 7.6 | 1.9 | 11.4 | 2.8 | 15.0 | 3.8 | 16.7 | 18.8 | 4.7 | 23.0 | 5.6 |

| Inductance (25℃,±20%)P-P | L | mH | 3.6 | 7.0 | 1.8 | 9.5 | 2.6 | 14.0 | 3.5 | 17.2 | 17.5 | 4.4 | 21.0 | 5.3 |

| Max Coil Temperature | Tmax | ℃ | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

| Polar Distance (N-N) (360℃ Electrical cycle) | 2τ | mm | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 | 60 |

| Magnetic Attraction | Fa | kN | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 | 0.0 |

| Max.DC Bus Voltage | Ubus | V | 330 | 330 | 330 | 330 | 330 | 330 | 330 | 330 | 330 | 330 | 330 | 330 |

| Vmax,Fc@Vbus=310Vdc | Vmax,Fc | m/s | 14.6 | 6.9 | 14.6 | 4.4 | 9.5 | 3.1 | 7.0 | 2.7 | 2.3 | 5.5 | 1.8 | 4.4 |

| Vmax,Fp@Vbus=310Vdc | Vmax,Fp | m/s | 10.8 | 3.4 | 10.8 | 0.8 | 5.9 | 0.0 | 3.4 | 0.4 | 0.0 | 1.9 | 0.0 | 0.9 |

| Vmax,0@Vbus=310Vdc | Vmax,0 | m/s | 15.4 | 7.7 | 15.4 | 5.1 | 10.3 | 3.9 | 7.8 | 3.4 | 3.1 | 6.2 | 2.6 | 5.2 |

| Mover Mass | Mp | Kg | 0.4 | 0.7 | 0.7 | 1.0 | 1.0 | 1.3 | 1.3 | 1.3 | 1.7 | 1.7 | 2.0 | 2.0 |

| Stator Mass within unit length | Ms | Kg/m | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 | 15.0 |

Dimension

| Mover Length | |||

| Mover model | Mover length L | M | Mover mounting hole A |

| LSMU510101A-S-H-NC-N-D00.5 | 61 | 1 | 3 |

| LSMU510201A-S-H-NC-N-D00.5 | 121 | 3 | 7 |

| LSMU510201A-P-H-NC-N-D00.5 | 7 | ||

| LSMU510301A-S-H-NC-N-D00.5 | 181 | 5 | 11 |

| LSMU510301A-P-H-NC-N-D00.5 | 11 | ||

| LSMU510402A-S-H-NC-N-D00.5 | 241 | 7 | 15 |

| LSMU510402A-P-H-NC-N-D00.5 | 15 | ||

| LSMU510501A-S-H-NC-N-D00.5 | 301 | 9 | 19 |

| LSMU510501A-P-H-NC-N-D00.5 | 19 | ||

| LSMU510601A-S-H-NC-N-D00.5 | 361 | 11 | 23 |

| LSMU510601A-P-H-NC-N-D00.5 | 23 | ||

Remark: 1. standard cable length is 0.5m with D-type aviation plug, maximum outer diameter of cable is 7.0mm, minimum bending radius of fixed laying is 3*d, minimum bending radius of dragging chain movement is 5*d, cable length and terminal can be customized.

2. optional temperature sensor.

| Stator Length | ||||

| Stator model | Stator length TL | N | Stator mounting hole B | Stator mounting hole C |

| LSMU5208A | 239.5 | 4 | 5 | 5 |

| LSMU5209A | 239.5 | 3 | 4 | 4 |

| LSMU5210A | 179.5 | 2 | 3 | 3 |

| LSMU5211A | 119.5 | 1 | 2 | 2 |

Suitable for any mover of this series, stator installation mode can be selected.

Industry Applications:

HAN’S LASER Group

Our Company Show

Production Line Show

Packaging & Delivery

Packaging Details.: plywood packing

Port.: Shenzhen (Sea / Air shipping, TNT, UPS, FedEx and DHL ect.)

Leading time: According to the order quantity, 10 days for the small order and 20 days for the bulk order

Sample

Contact Us

Experience our expert support, tailored solutions, and reliable global delivery.

Related Products

Features

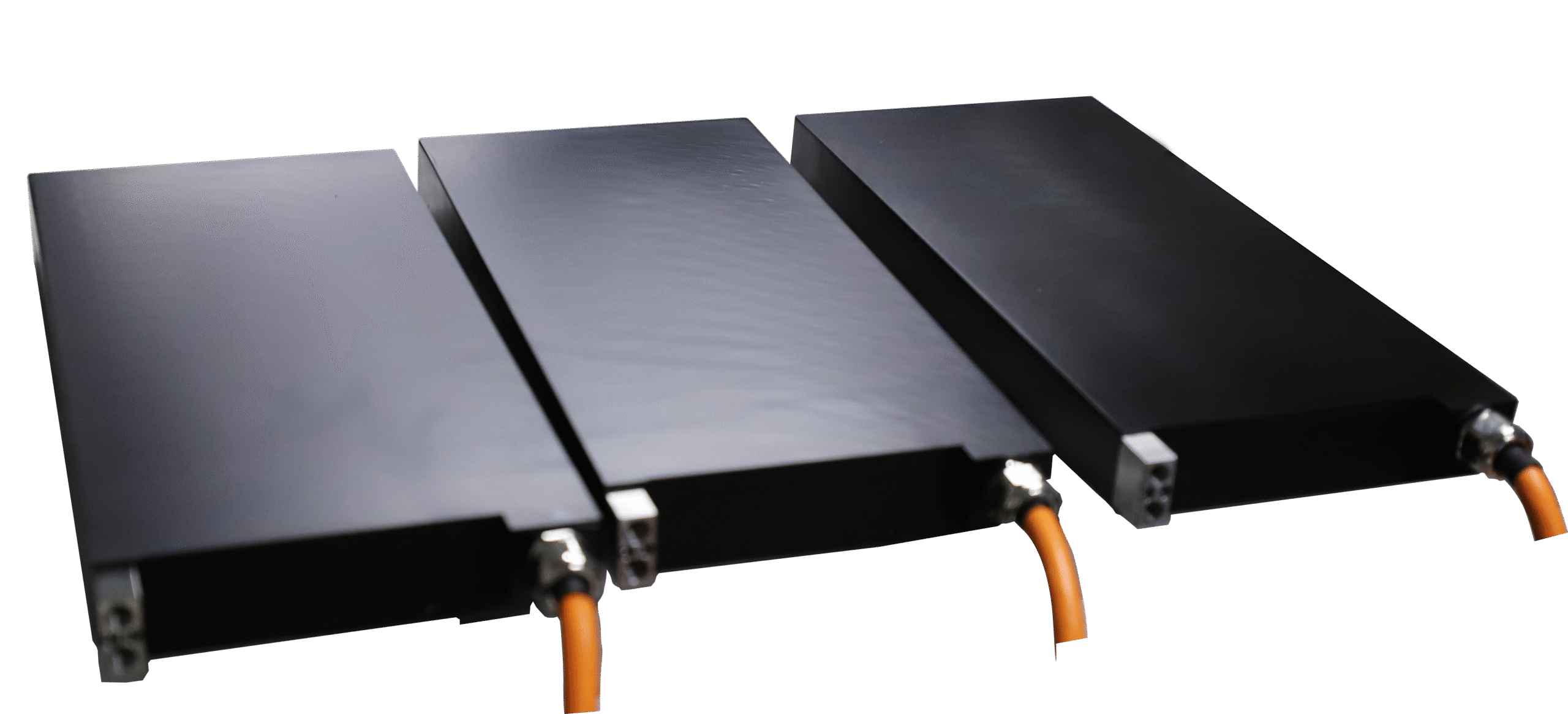

Semiconductor ironless lienar motor is also called carbon fiber board motor with feature high speed, high acceleration, high thrust density and efficient heat dissipation, enabling stable high-performance operation in semiconductor applications.

Features

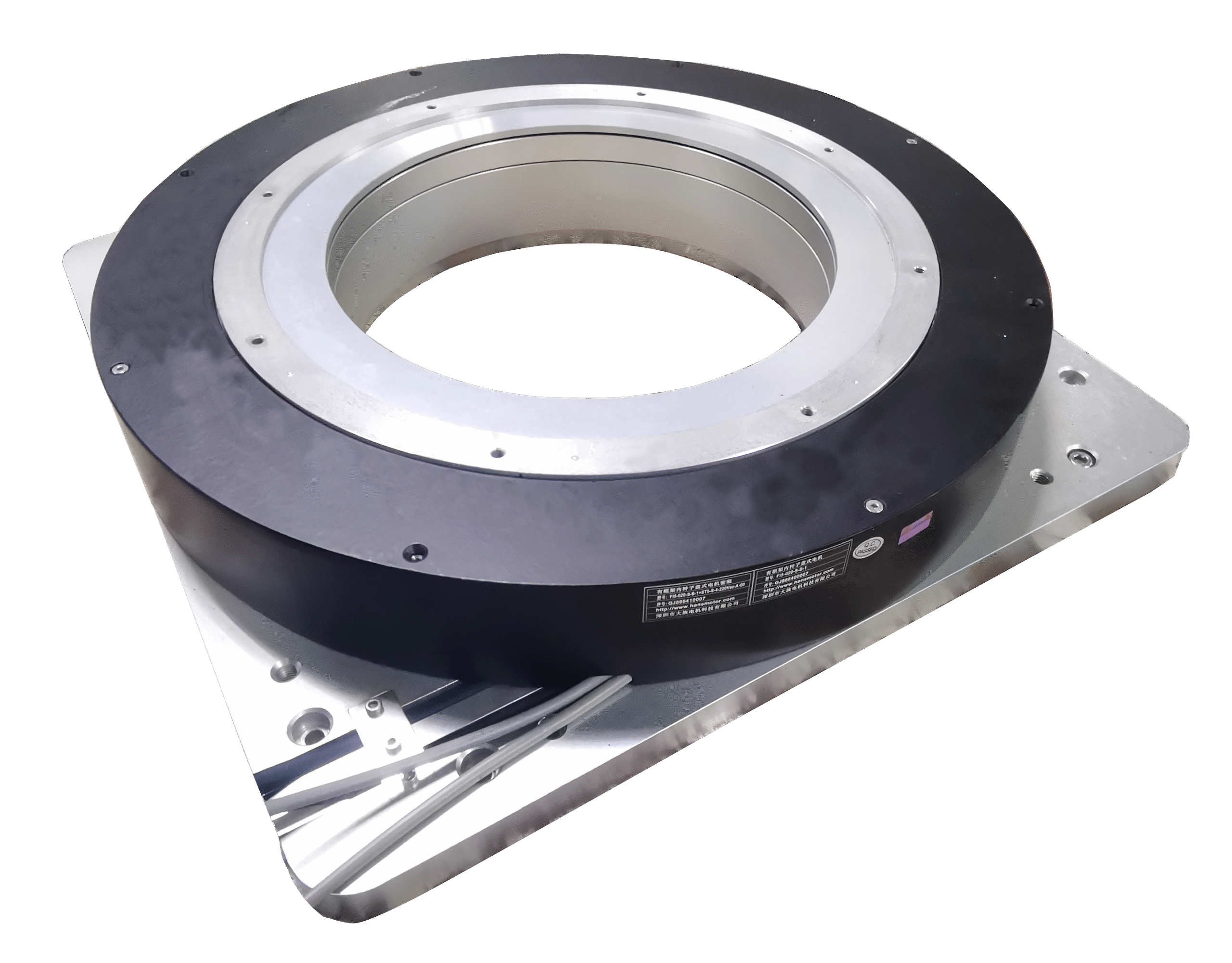

FE3 Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

This linear motor is specially designed for semiconductor packaging equipment, featuring high precision, fast response, and stable performance to meet the demanding requirements of advanced packaging processes.

Features

LSMFK series Water-Cooled Ironcore Linear Motors feature high thrust density 10000Nm and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

LSMD2 series double-sided magnet ironcore linear motor adopt gas cooling technology, high thrust with superior acceleration, cogging torque reduction technology, built-in thermal protection, and cancellation of unbalanced electromagnetic forces in demanding applications.