Introduction

The moment you plan a project that needs force rather than speed, a high-torque motor is one of the elements that comes to your mind at once. So whether you are working on designing a robot arm, the conveyor, or the heavy-duty actuator, the right motor comes as a perfect way of getting through by knowing the torque needs, speeds, various environmental conditions, and many little but important details. This guide helps you find the best motor for your job.

Key Takeaways

- Calculate the torque needed to properly operate your system, which also needs to be accelerated.

- While trying to match speed (RPM) to the capacity of the load, don’t forget to use gearboxes if necessary.

- Consider features such as control, maintenance, and performance to decide on the appropriate motor type (brushed, brushless, servo, etc.).

- Think about the surrounding factors: heat, water, dirt, and shake.

- Double-check that power specs (voltage, current) are consistent with your supply.

Shop around suppliers for reliability, cost vs. performance, and warranty.

1. Torque & Load

Calculating Required Torque

To decide what size of high-torque motor you need, follow these steps:

| Step | What to do |

| Force estimation | Determine the force needed: mass × acceleration (e.g., for lifting or pushing). |

| Distance (radius) | Measure the distance from the motor shaft to the point of force application. |

| Torque formula | Use: Torque = Force × Radius. |

| Acceleration torque | If your load must speed up or decelerate quickly, factor that in. |

| Safety margin | Multiply the result by 1.5–2× so the motor isn’t overstressed under real conditions. |

Understanding Your Load Profile

That one load point is not enough. You should consider the entire operating cycle in your thinking.

- Peak loads: short runs when torque shoots up.

- Duty cycle: the ratio of on-time to off-time.

- Load type: Are the forces caused by the load pushing the shaft sideways (radial) or along its length (axial)?

- Inertia matching: if the motor and load inertia are improperly paired, the performance will be slow, or there will be unsteady vibrations.

2. Speed & RPM Needs

In many motor cases, speed and torque have an inverse relationship:

- If you want strong torque at low speed, go lower (employ high-ratio gearboxes).

- You can get both speed and torque by choosing the right motors.

- Never forget to consult the torque-speed curve of a motor. A motor with high torque is often one whose RPM decreases as the load increases. Without the use of a transmission, the application of a heavy load at low RPM can result in overheating and subsequent failure of the motor.

3. Types of High Torque Motors

Different motor types suit different needs. Here’s a comparative view:

| Motor Type | Structure & Design | Key Advantages | Typical Applications |

| Frameless Inner Rotor Torque Motor | Compact, no housing; directly integrated into the machine | Fast response, low inertia, high precision | Robotic joints, rotary tables, precision instruments |

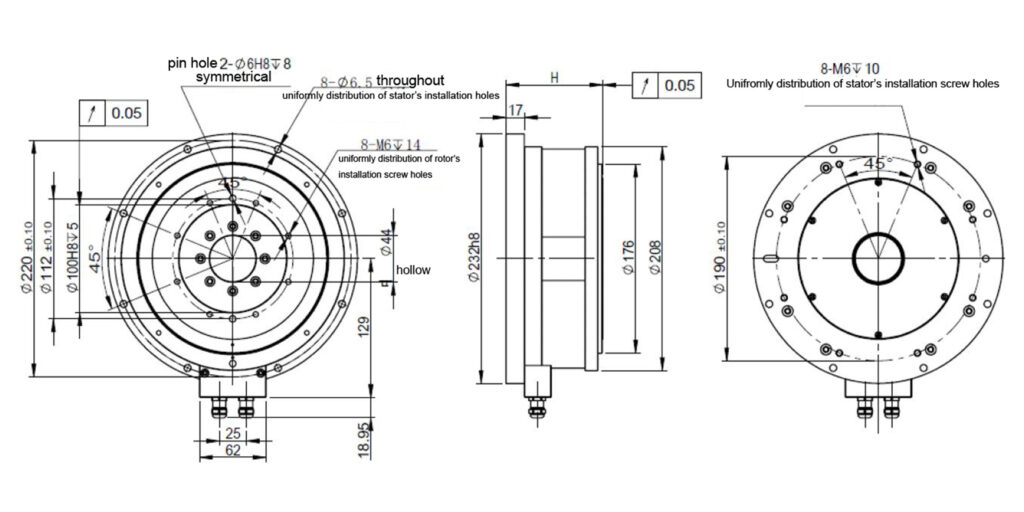

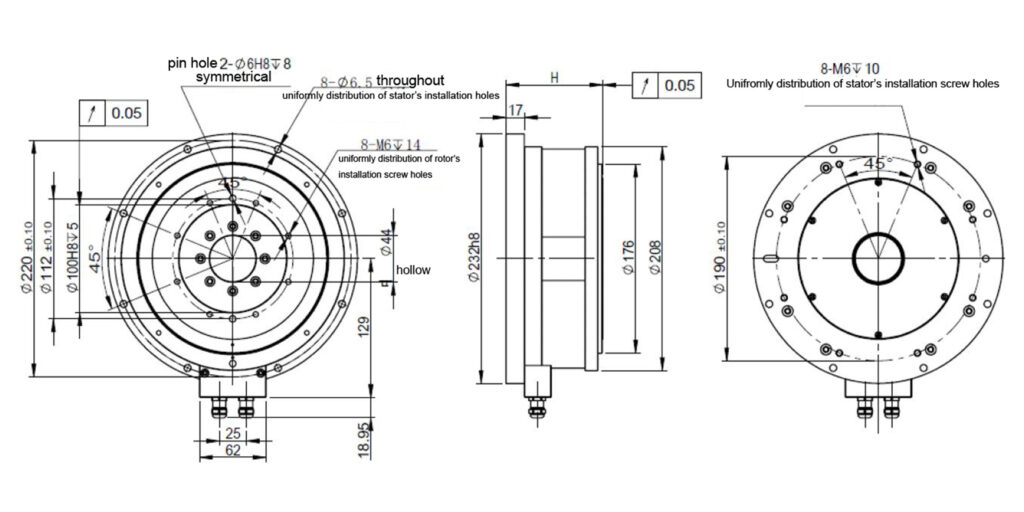

| Frame Inner Rotor Torque Motor | With housing + inner rotor | High rigidity, stable operation, easy installation | CNC machines, automation equipment, precision machinery |

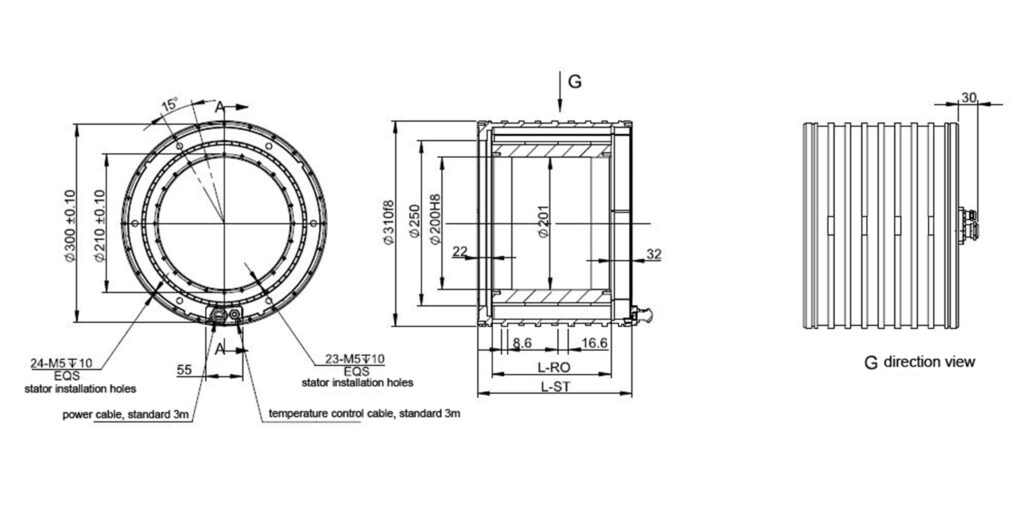

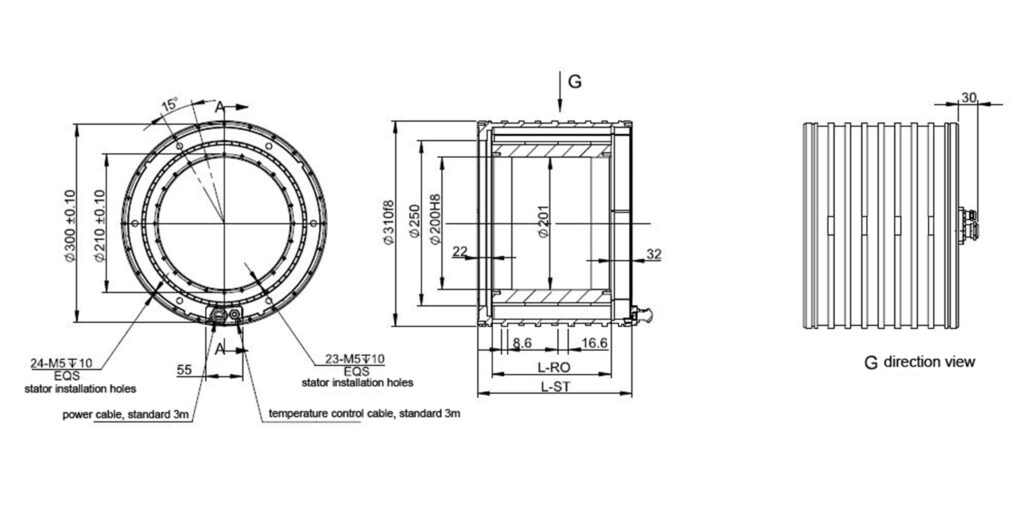

| Frame Outer Rotor Torque Motor | With housing + outer rotor | Large torque output, good heat dissipation, optimized inertia | Rotary tables, heavy-duty platforms, rotating axes |

| High Torque Direct-Drive Motor | Direct drive, no gear or transmission | High torque density, zero backlash, fast response, high precision | Semiconductor tools, inspection platforms, high-accuracy rotary systems |

A high torque motor provides the force, precision, and stability needed in demanding applications. With strong output and reliable performance, it ensures accurate motion control and long-term durability across different industries.

4. Environment & Duty Conditions

Where and how the motor operates matters a lot.

- Temperature & Humidity: Raising the temperature will reduce the efficiency of the motor, while introducing moisture will reduce the insulation of the motor and corrode the parts. Besides that, motor magnets can be damaged if too much heat is applied.

- Dust, Chemicals & Water: Motors with proper sealing (IP ratings) and coatings or that are built for hazardous locations should be selected to suit the need.

- Vibration & Mounting: Faulty alignment, loose fasteners, or using the wrong type of mounts can cause the parts to wear out earlier. Install vibration damping or rubber mounts wherever necessary. For vertical installations, you have to do shaft alignment, bearing loads, and lubrication very carefully.

5. Cost, Supplier & Support

To put it briefly, motor specs cannot save you if the motor fails or parts and support can’t be accessed. The points to remember are:

- Cost vs. Life: A motor with high torque that is pricier but has a longer service life and lower maintenance can be more economical in the long term.

- Supplier reputation: Number of years in business, certifications (ISO, CE, etc.), capability of supplying test data.

- Warranty & After-sales: The good warranty is a reflection of the supplier’s confidence in the product. Therefore, apart from that, make sure spare parts are easily accessible.

- Customization: Sometimes, you need nonstandard shaft types, mounting flanges, or gearboxes, so a manufacturer who can customize them is helpful.

FAQs

Q1: How do I know my motor’s torque will be enough?

A1: You should calculate the torque using the formula (Force × Radius), add the parts for acceleration if that is the case, and finally, use a safety margin (1.5-2×) so that the motor is not under stress.

Q2: Can I use a high-torque motor outdoors?

A2: Yes, but this is only true if the device has proper sealing (a good IP rating), is protected from water vapor, and is made from materials suitable for extreme temperatures.

Q3: Why does my motor run hot even though it meets specs?

A3: Possible causes include incorrect voltage, overloading beyond rated torque, ventilation restriction, high ambient temperature, and continuous duty without rest.

Q4: Is the use of a gearbox always advantageous?

A4: Gearboxes can increase torque and reduce speed, but they also create friction that reduces efficiency, complicates the system, and requires maintenance.

Conclusion

Choosing the right high-torque motor means more than picking the highest number you can afford. In different applications, the choice of motor is determined by torque requirements, load conditions, and environmental factors. Choosing the right high-torque DC motor can significantly improve equipment performance and reduce failures.If you like, I can prepare an optimized meta title, description, and suggested images to go with this article.