Products

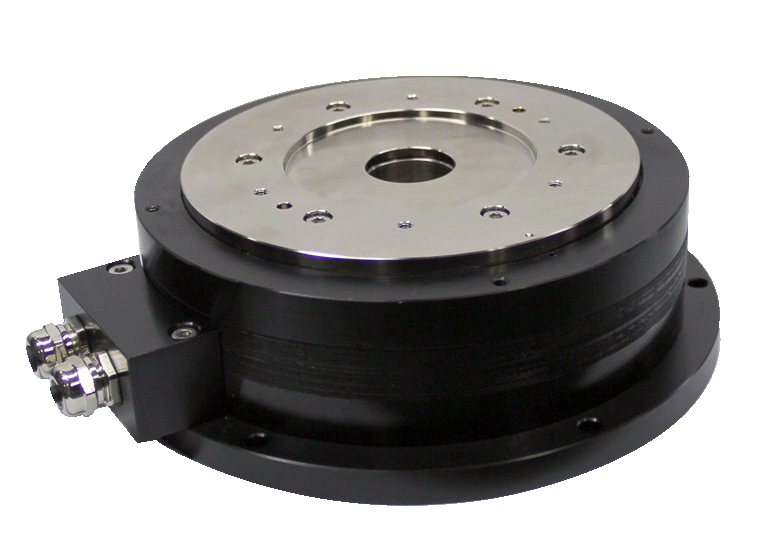

DC24V 25Nm torque motor

The DC24V 25Nm torque motor is an industrial-grade powerhouse designed for high-precision, low-speed applications. It delivers smooth, controllable torque with extremely fast response times, making it perfect for constant tension control, direct drive systems, and precision industrial machinery. This motor combines reliable performance, high torque output, and precise control, making it a top choice for engineers and manufacturers seeking durable and efficient torque solutions.

Brand:

Order(MOQ):

1

Product Detail

Feature:

1.High Dynamic Direct Drive – Provides smooth and responsive torque output for low-speed, high-precision industrial applications.

2.Precision Feedback – Equipped with Han’s self-developed BISS-C interface absolute position feedback for reliable DC24V torque motor control.

3.Inner Rotor & Low-Speed Windings – Ensures stable torque performance across low-speed operations.

4.Wide Torque Range – Torque output from 14 Nm to 310 Nm, suitable for various industrial and automation scenarios.

5.Driver Compatibility – Works with Han HX-RC010D48 low-voltage driver (14V-60VDC) and Servotronix drivers, supporting RS485 and CANopen communication interfaces.

6.Customizable Solutions – Tailored development available to meet specific industrial application requirements.

Highlights:

· High Torque & Precision – DC24V torque motor delivers smooth, controllable torque from low speeds, ideal for precision industrial applications.

· Direct Drive Performance – Features fast dynamic response and stable torque output for low-speed, high-accuracy operations.

· Advanced Position Feedback – Integrated BISS-C absolute encoder ensures accurate motor control and reliability.

· Inner Rotor Design – Optimized for efficient low-speed torque and long-term durability.

· Wide Torque Range – Supports 14 Nm to 310 Nm, suitable for diverse automation and direct drive systems.

· Driver & Communication Compatibility – Works seamlessly with Han HX-RC010D48 low-voltage driver and Servotronix drivers, supporting RS485 & CANopen interfaces.

· Customizable Solutions – Motor development can be tailored to meet specific industrial and automation requirements.

Application:

DC24V torque motor is widely used in winding/unwinding machinery, robotics & automation equipment, testing and measurement devices, military and aerospace systems, as well as other precision equipment.

Specification

| Performance Parameters | |||

| Motor Model | Symbol | Unit | HANS-G-025-D208-H090-T43-1-D |

| Max.working voltage | Vdc | V | 24 |

| Continuous current (Tmax) | Ic | Arms | 8.4 |

| Peak Current (Tmax) | Ic | Arms | 25 |

| Continuous torque (Tmax) | Tc | Nm | 25 |

| Peak torque(Tmax) | Tc | Nm | 72 |

| Max.speed (Tc=25NM) | Nmax | Rpm | 30 |

| Max.speed (Tc=0NM) | Nmax | Rpm | 80 |

| Absolute encoder (BISS-C) | P/rev | 23bits | |

| Positioning Accuracy | arc sec | ±15 | |

| Repeat Accuracy | arc sec | ±2 | |

| Electrical specification | |||

| Torque Constant (within 25℃±5℃) | Tf | N/Arms | 2.98 |

| Electromotive constant (within 25℃±5℃) | Te | Vrms/rad/s | 0.99 |

| Resistance (within 25℃±5℃) | R | Ω(p-p) | 0.9 |

| Inductance (within 25℃±5℃) | L | mH | 2.5 |

| IP grade | IP40 | ||

| Max.No Load Current | I0 | Arms | 0.6 |

| Max.static friction | Nm | 2 | |

| Electrical time constant | ms | 2.78 | |

| Working temperature | ℃ | -40~+60 | |

| Pole pairs | p | 16 | |

| Max.coil temperature | Tmax | ℃ | 120 |

| Mechanical specification | |||

| Motor Mass | KG | 17 | |

| Mover Mass | Mc | KG | 6 |

| Rotor Moment of Inertia | Jm | Kg*m2 | 0.015 |

| Axial Runout | mm | 0.05 | |

| Radial Runout | mm | 0.05 | |

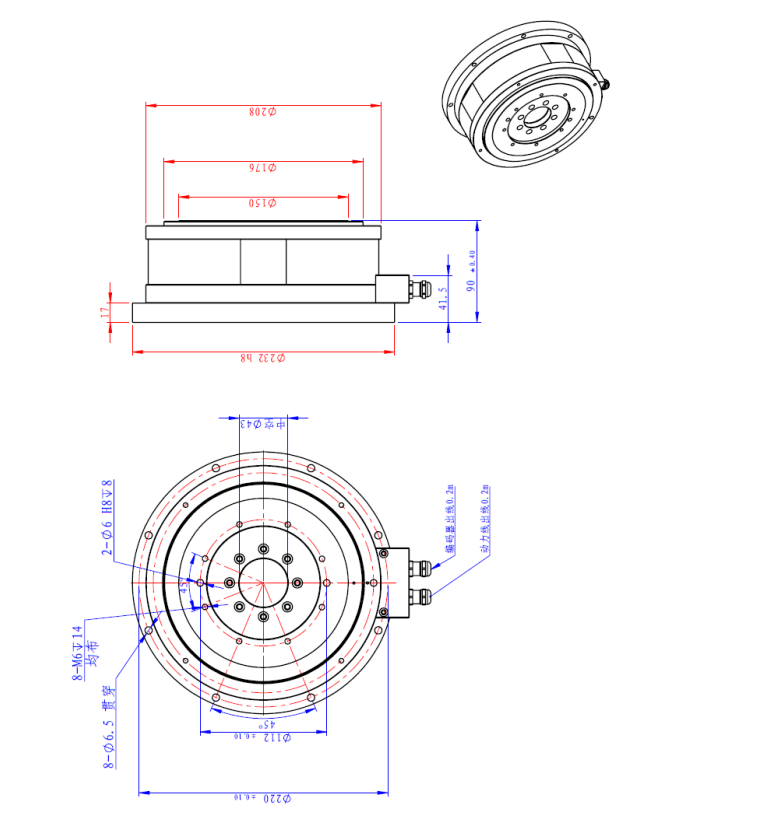

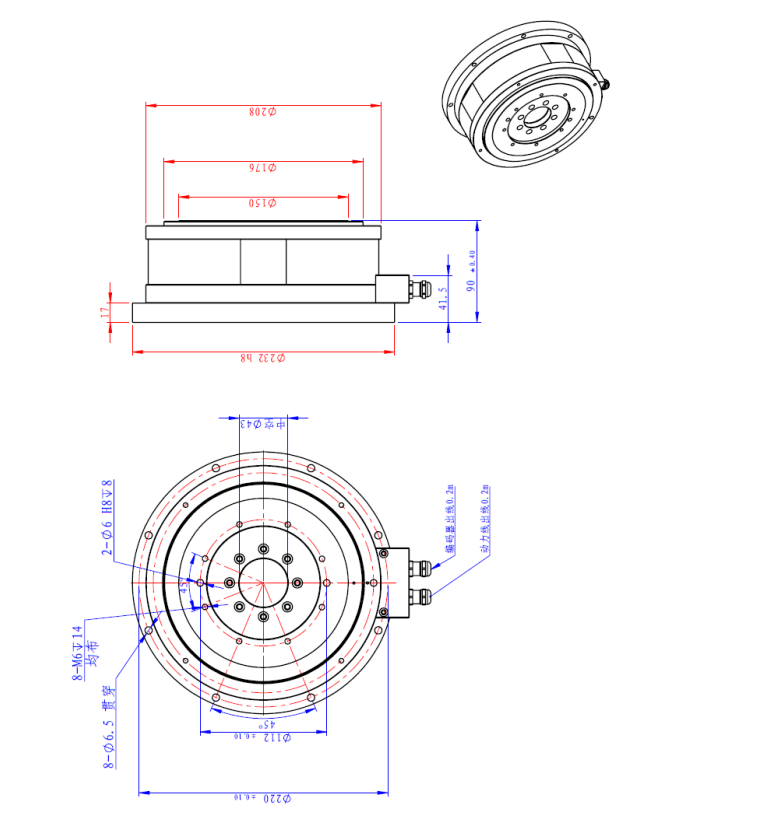

Dimension

Sample

Contact Us

Experience our expert support, tailored solutions, and reliable global delivery.

Related Products

Features

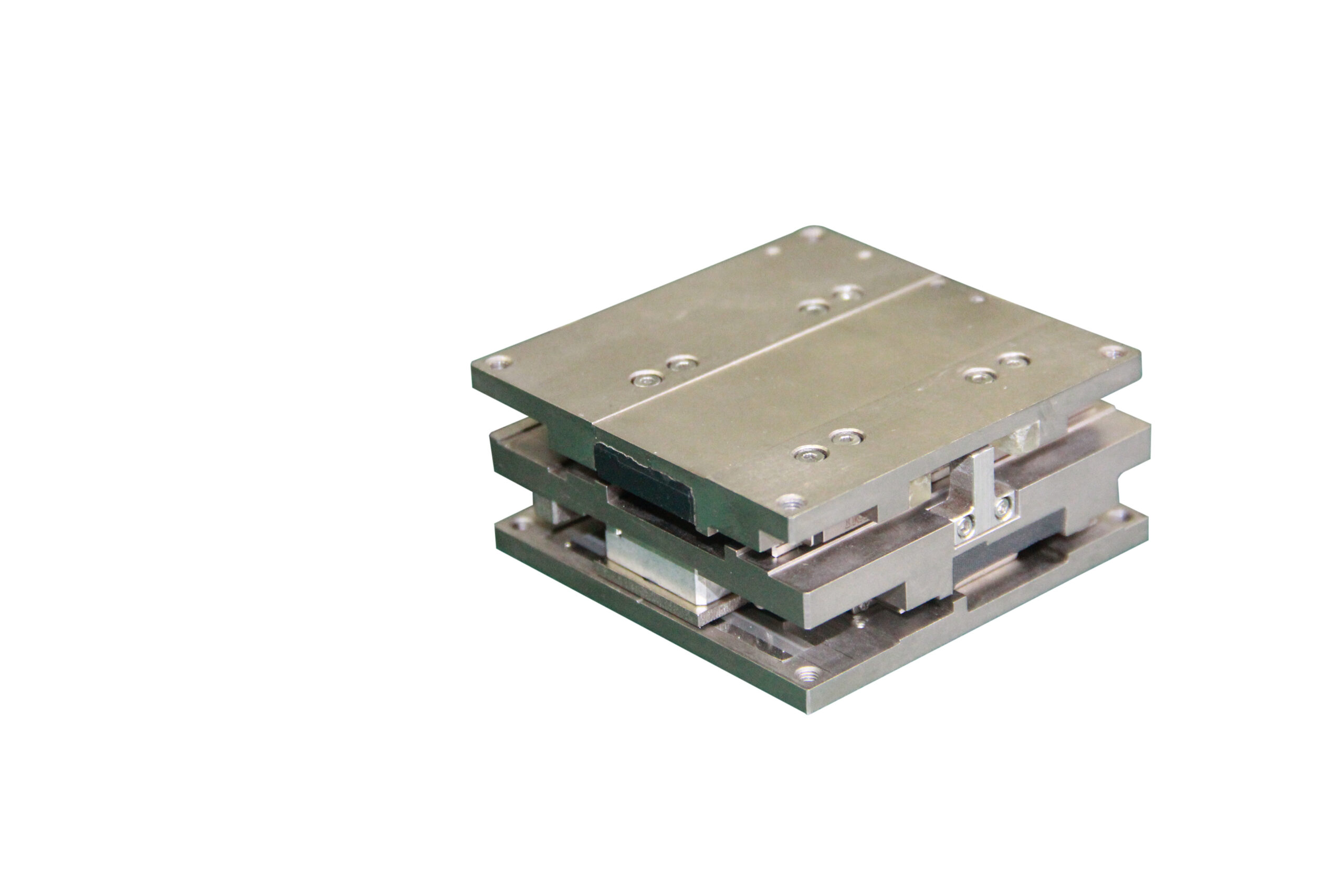

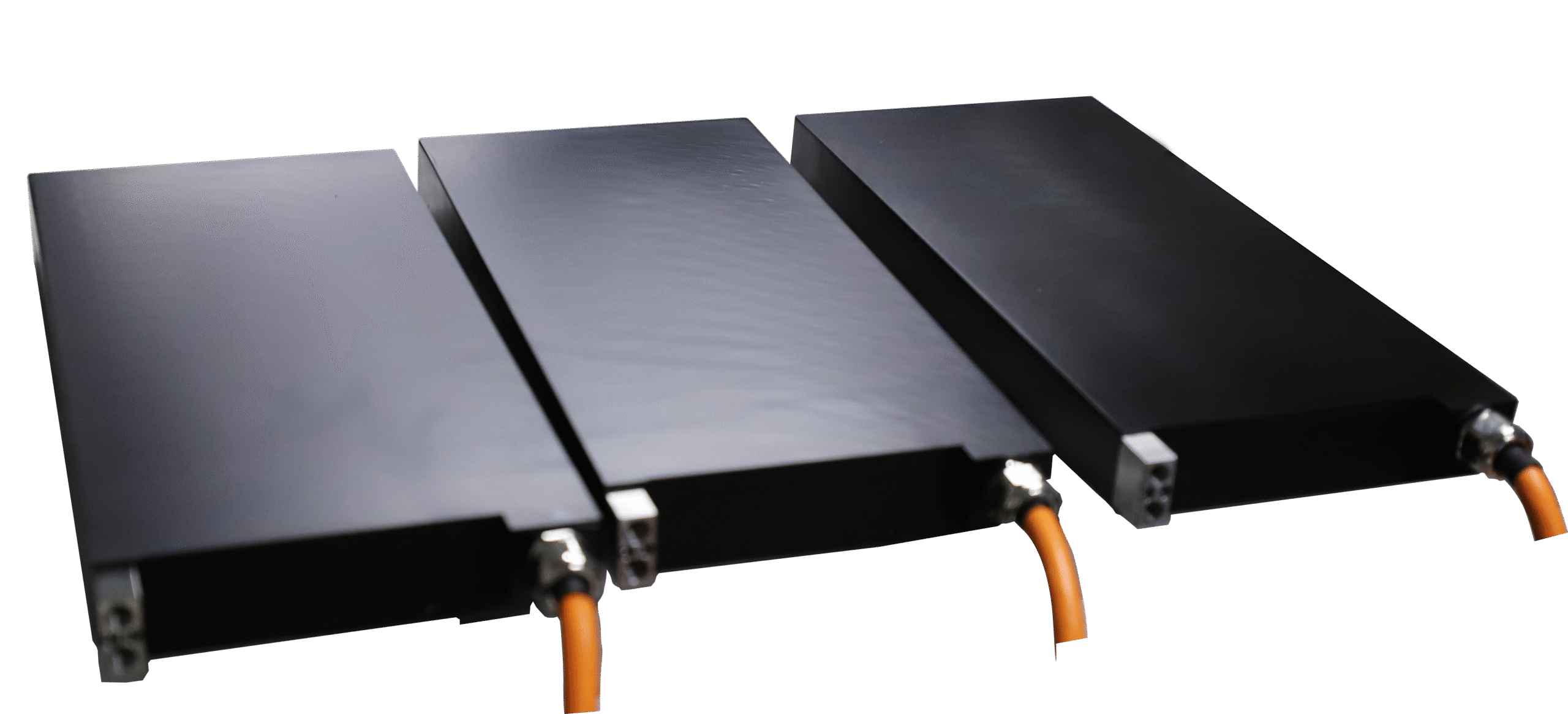

Semiconductor ironless lienar motor is also called carbon fiber board motor with feature high speed, high acceleration, high thrust density and efficient heat dissipation, enabling stable high-performance operation in semiconductor applications.

Features

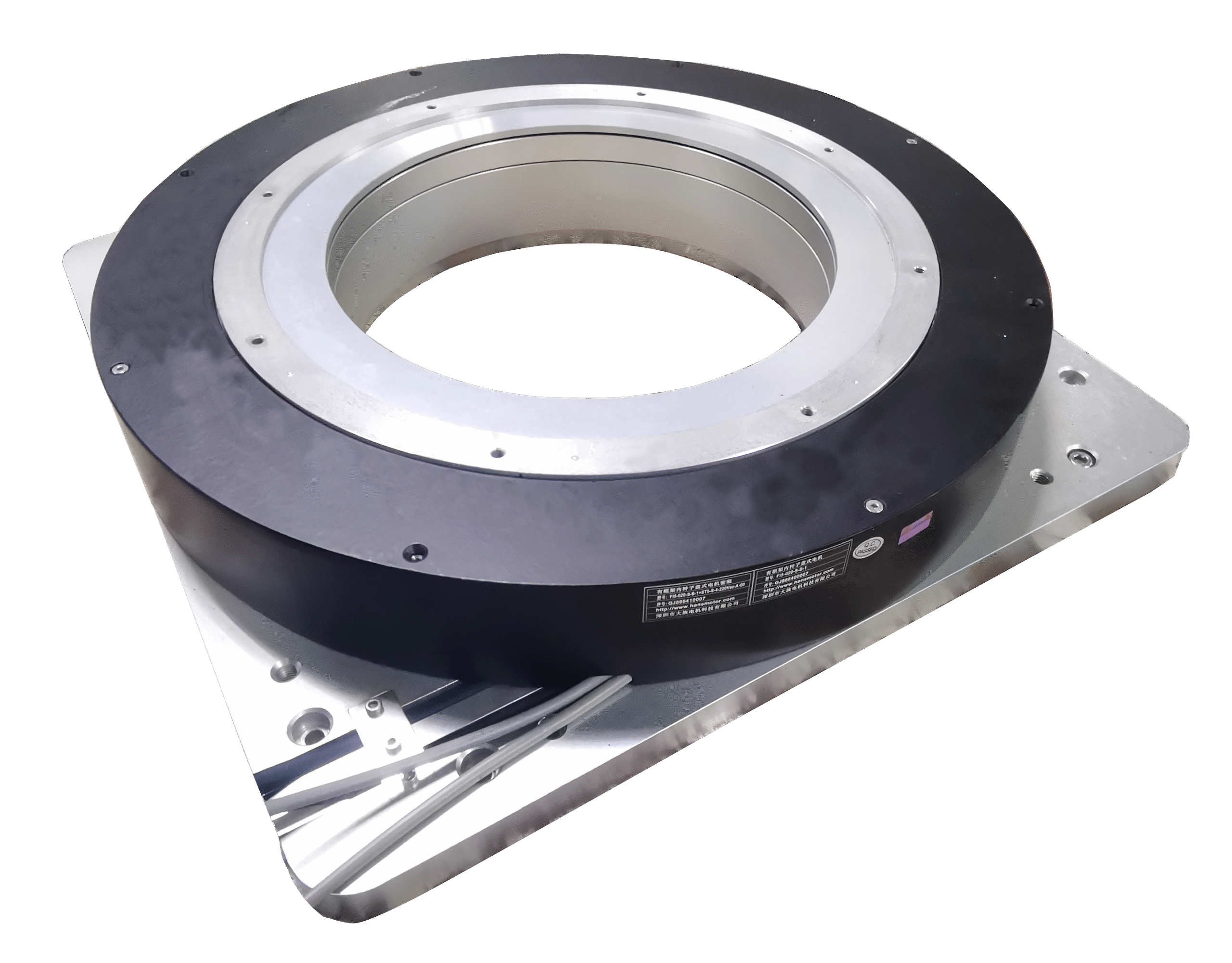

FE3 Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

This linear motor is specially designed for semiconductor packaging equipment, featuring high precision, fast response, and stable performance to meet the demanding requirements of advanced packaging processes.

Features

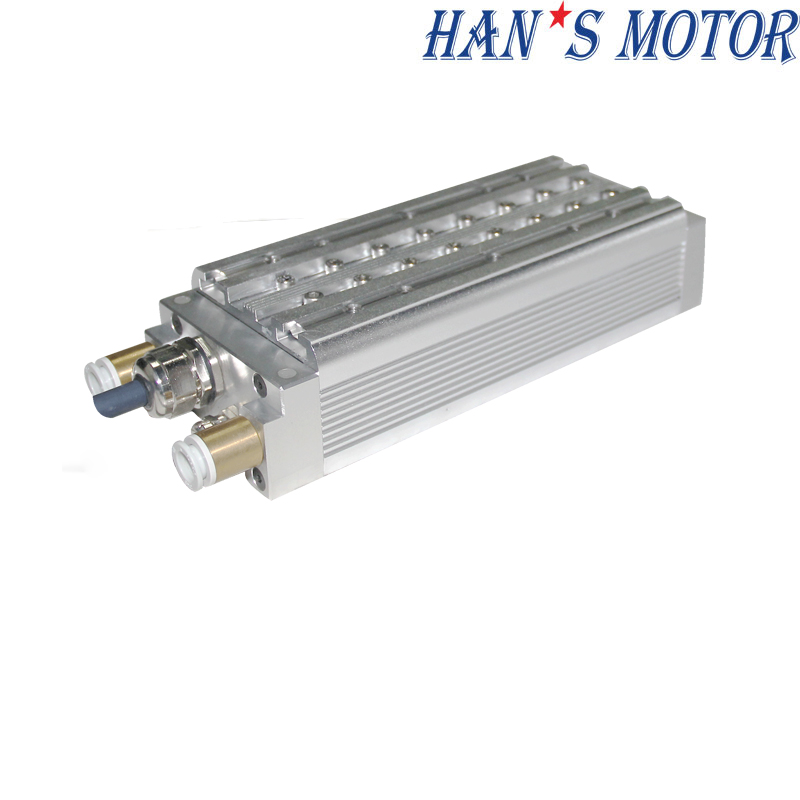

LSMFK series Water-Cooled Ironcore Linear Motors feature high thrust density 10000Nm and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

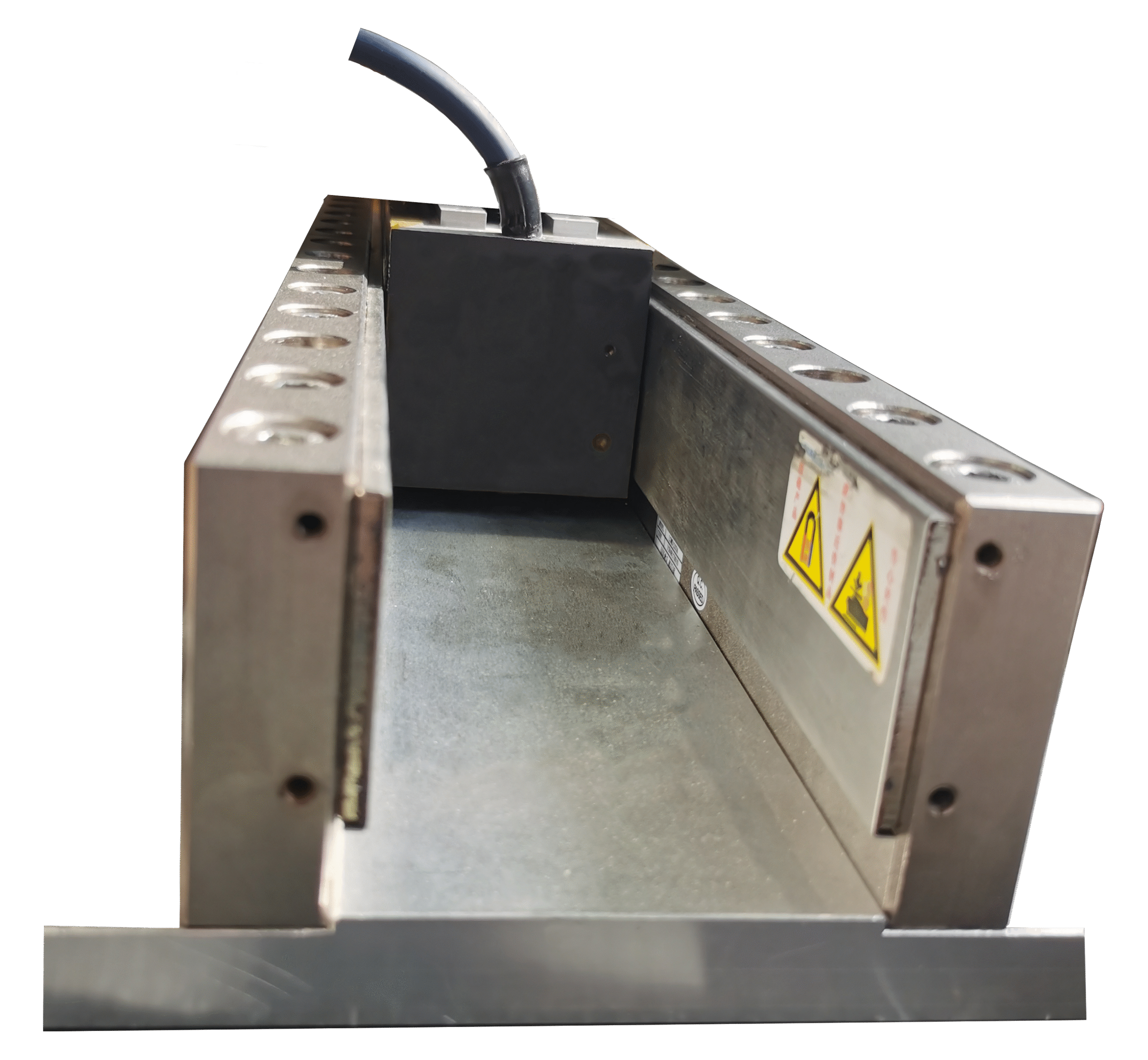

LSMD2 series double-sided magnet ironcore linear motor adopt gas cooling technology, high thrust with superior acceleration, cogging torque reduction technology, built-in thermal protection, and cancellation of unbalanced electromagnetic forces in demanding applications.