Products

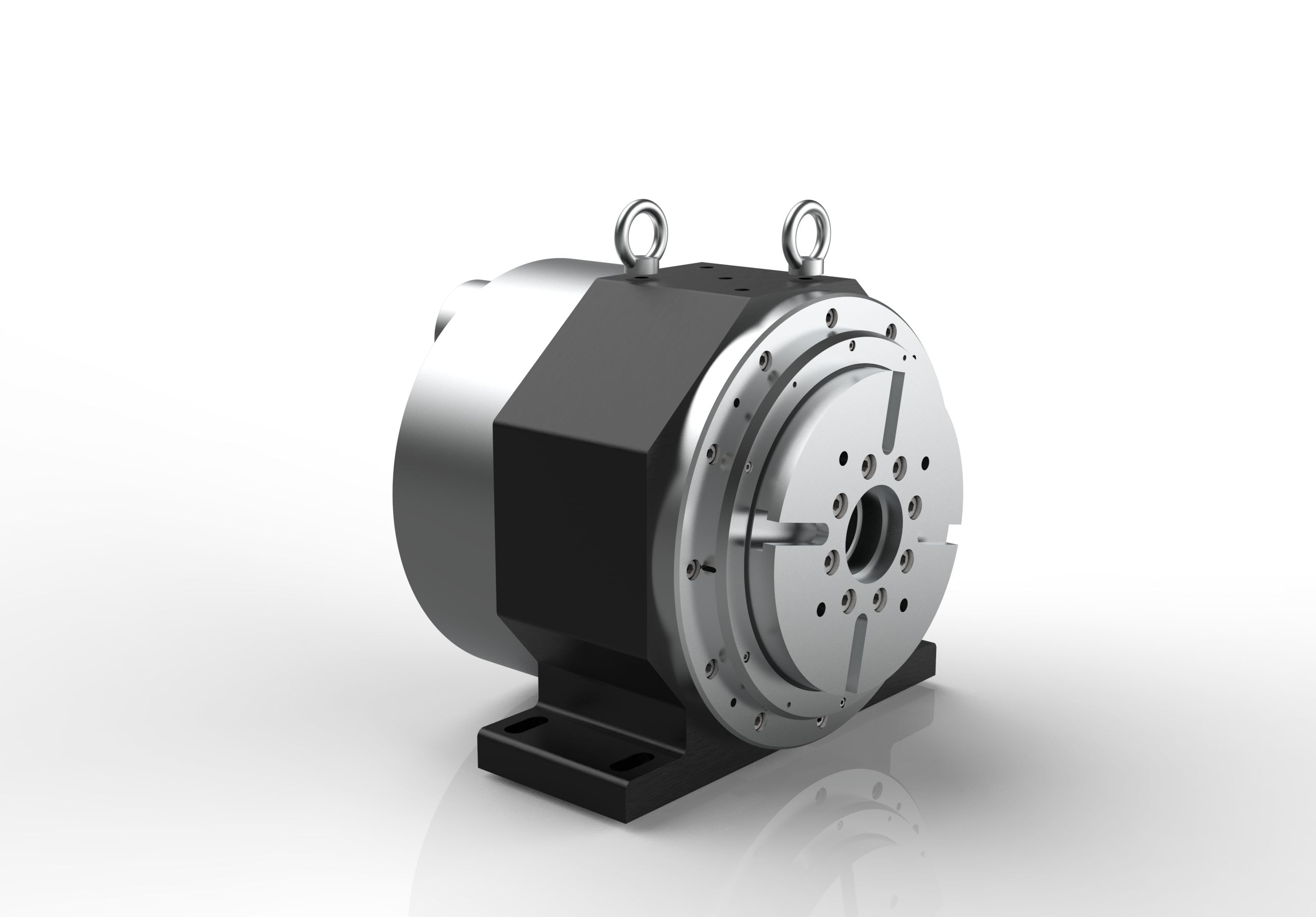

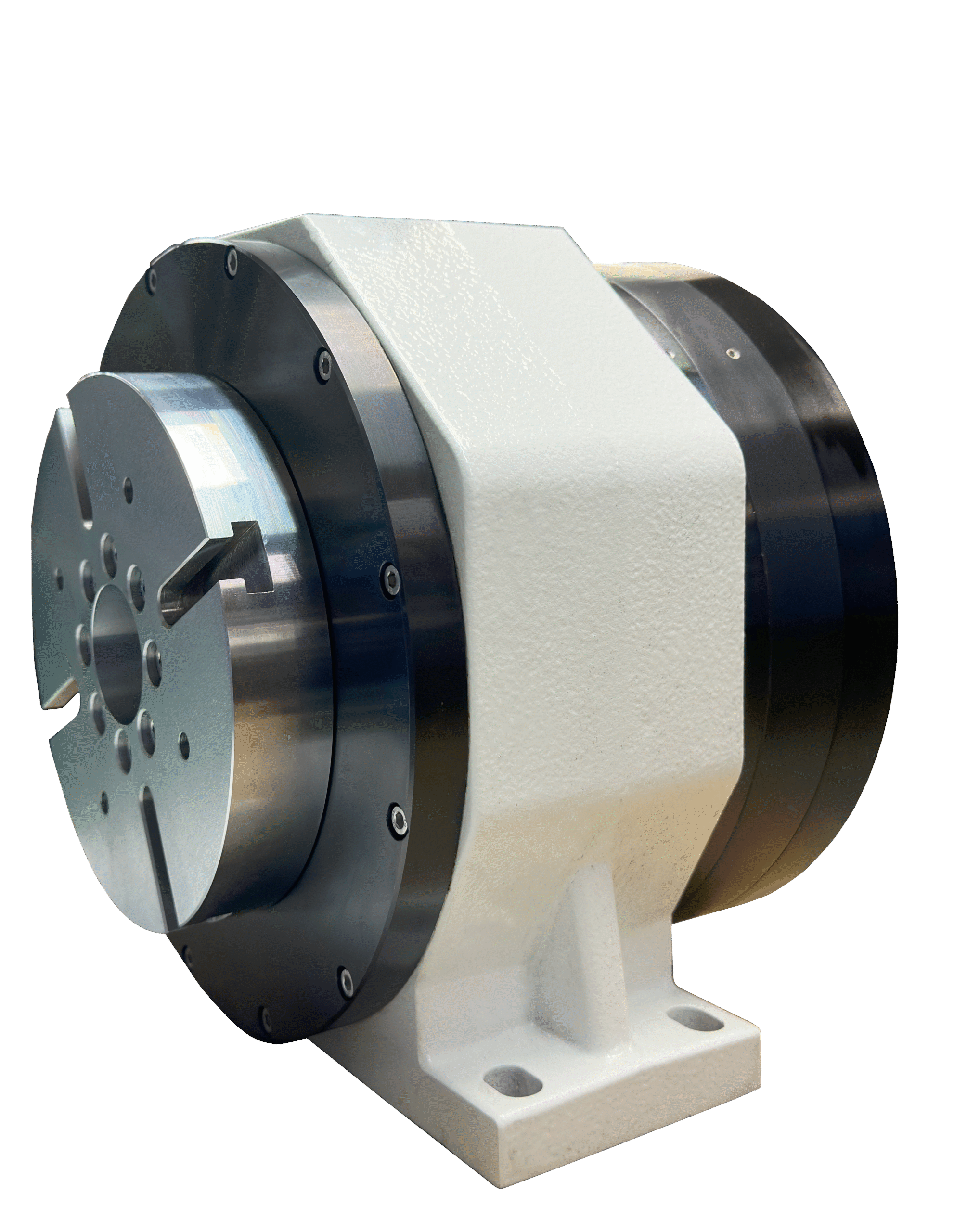

Direct Drive Rotary Table

Our Direct Drive Rotary Tables deliver ultra-precise rotation for CNC machining, semiconductor manufacturing, robotics, automation, and optical instruments. Designed for medical equipment, new energy, aerospace, and defense applications, these rotary tables ensure high accuracy, smooth operation, and reliable performance in demanding industrial environments.

Brand:

Order(MOQ):

1

Product Detail

Feature:

High Speed: Direct drive by torque motor enables up to 200 rpm, much faster than worm-gear tables (25–44 rpm), ideal for high-efficiency CNC machining, robotics, and automation.

High Precision: Equipped with a high-precision absolute encoder, achieving ±2 μm repeatability. Zero-backlash direct-drive technology delivers 3–4× higher accuracy than traditional worm-gear tables.

High Reliability: IP65-protected sealed design with optional contamination-resistant optical encoders, ensuring stable performance in semiconductor, medical, and aerospace applications.

Powerful Brake: Cylinder-piston brake supports high-torque cutting, enhancing safety and machining stability.

Maintenance-Free: Wear-free direct-drive transmission eliminates regular worm-gear maintenance, reducing costs and improving operational efficiency.

Highlights:

1.Compact & Robust Design: Space-saving structure suitable for CNC machines, robotics, and automation systems.

2.Smooth & Stable Operation: Minimizes vibration and torque fluctuation for precise machining results.

3.Energy-Efficient Performance: Direct-drive technology reduces energy loss and operational costs.

4.Wide Industrial Application: Ideal for semiconductor processing, medical equipment, aerospace, and optical instruments.

5.Enhanced User Experience: Simple integration with control systems and minimal maintenance requirements.

Application:

Direct-drive rotary tables are widely used in precision machining, semiconductor and electronics manufacturing, robotics and automation, optical and measurement instruments, medical equipment, new energy and material processing, as well as aerospace and defense applications.

Specification

| Motor Model: HSLD-90-90-600-25-A23-A4 | 90-600-25 | ||

| Performance Parameters | Symbol | Unit | |

| Continuous Torque (at Tmax) | Tc | Nm | 25 |

| Peak Torque | Tp | Nm | 75 |

| Max. Speed | Nmax | Rpm | 530 |

| Repeatability | Arc sec | ±1 | |

| Positioning Repeatability | Arc sec | ±10/±5 | |

| Maximum Axial Load (Recommended) | N | 3000 | |

| Maximum Torque Load (Recommended) | Nm | 200 | |

| Continuous Current (at Tmax) | Ic | Arms | 4.3 |

| Peak Current (1s Duration) | Ip | Arms | 13 |

| Torque Constant(25℃,±5%) | Kt | Nm/Arms | 5.75 |

| Back-EMF Constant | Ke | Vrms/rad/s | 1.92 |

| Resistance(25℃,±5%) | R | Ω(p-p) | 2.5 |

| Inductance(25℃,±5%) | L | mH(p-p) | 7.4 |

| Number of Pole Pairs | p | 16 | |

| Maximum Allowable Coil Temperature | Tmax | ℃ | 120 |

| Motor Mass | Kg | 25 | |

| Rotor Mass | Mr | Kg | 6 |

| Rotor Inertia | Jm | Kg*m2 | 0.02 |

| Axial Runout | mm | 0.05 | |

| Radial Runout | mm | 0.05 | |

| Motor Cable Length ( Extendable Optional) | L | M | 0.2 |

| Minimum Cable Bending Radius | R | mm | 37.5 |

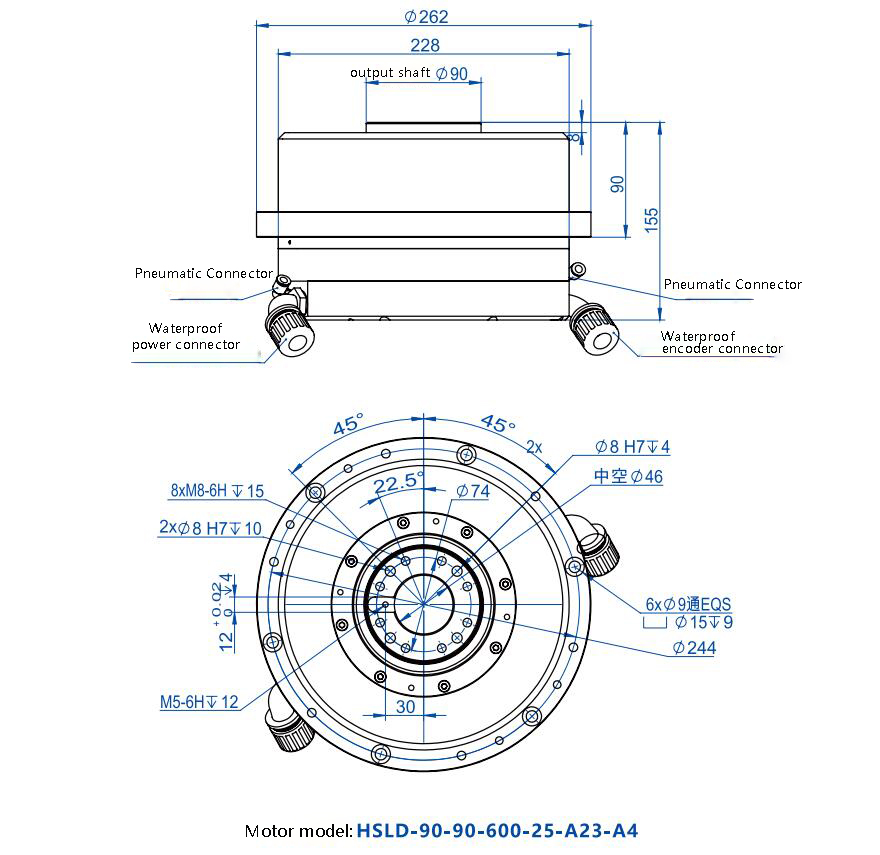

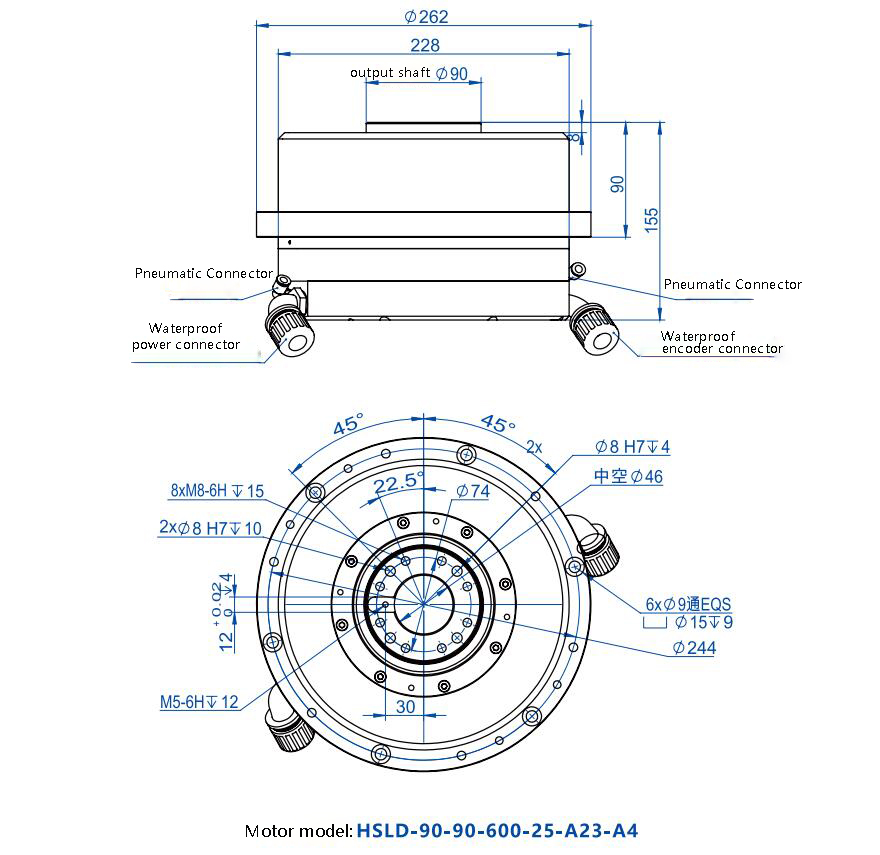

Dimension

Sample

Contact Us

Experience our expert support, tailored solutions, and reliable global delivery.

Related Products

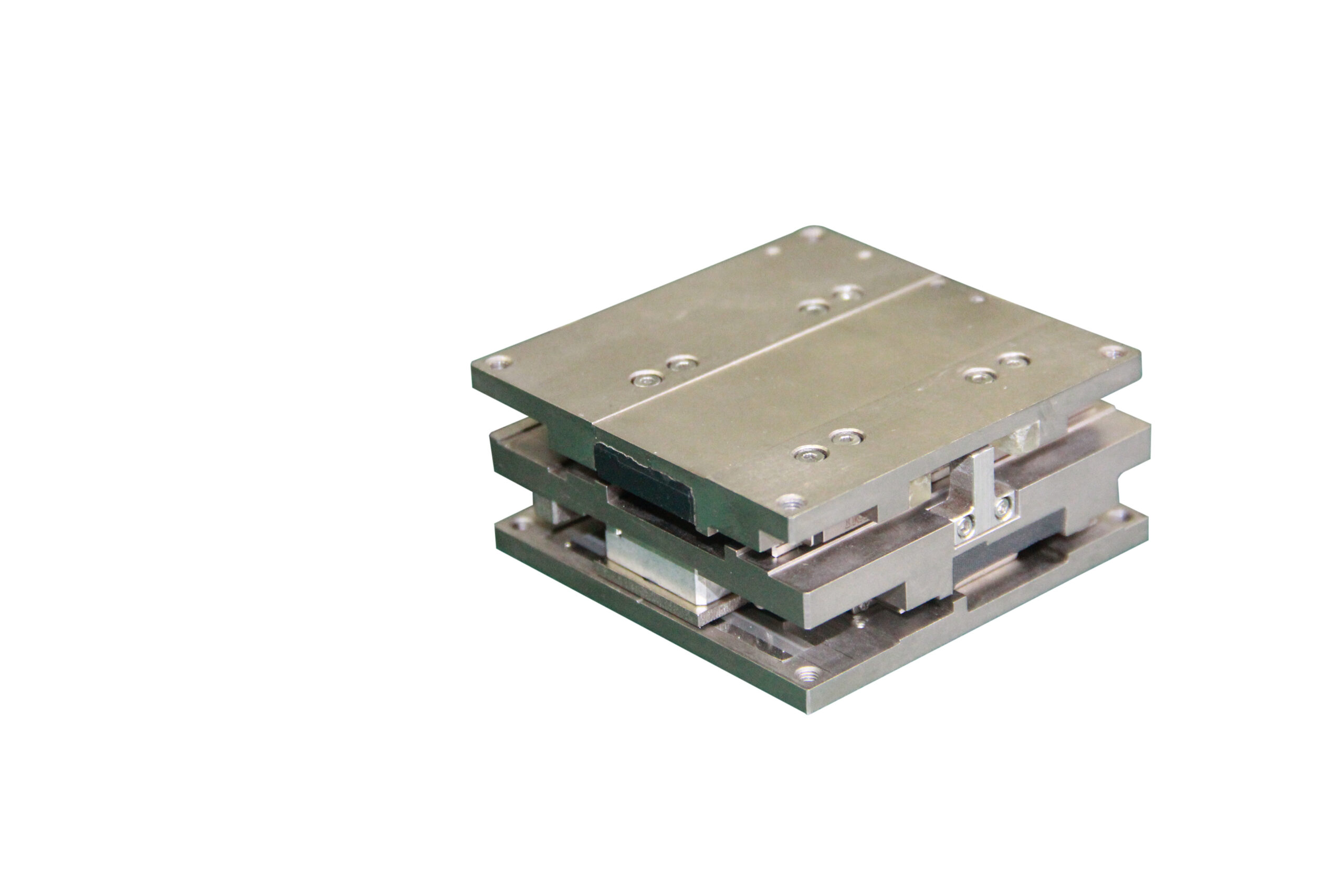

Features

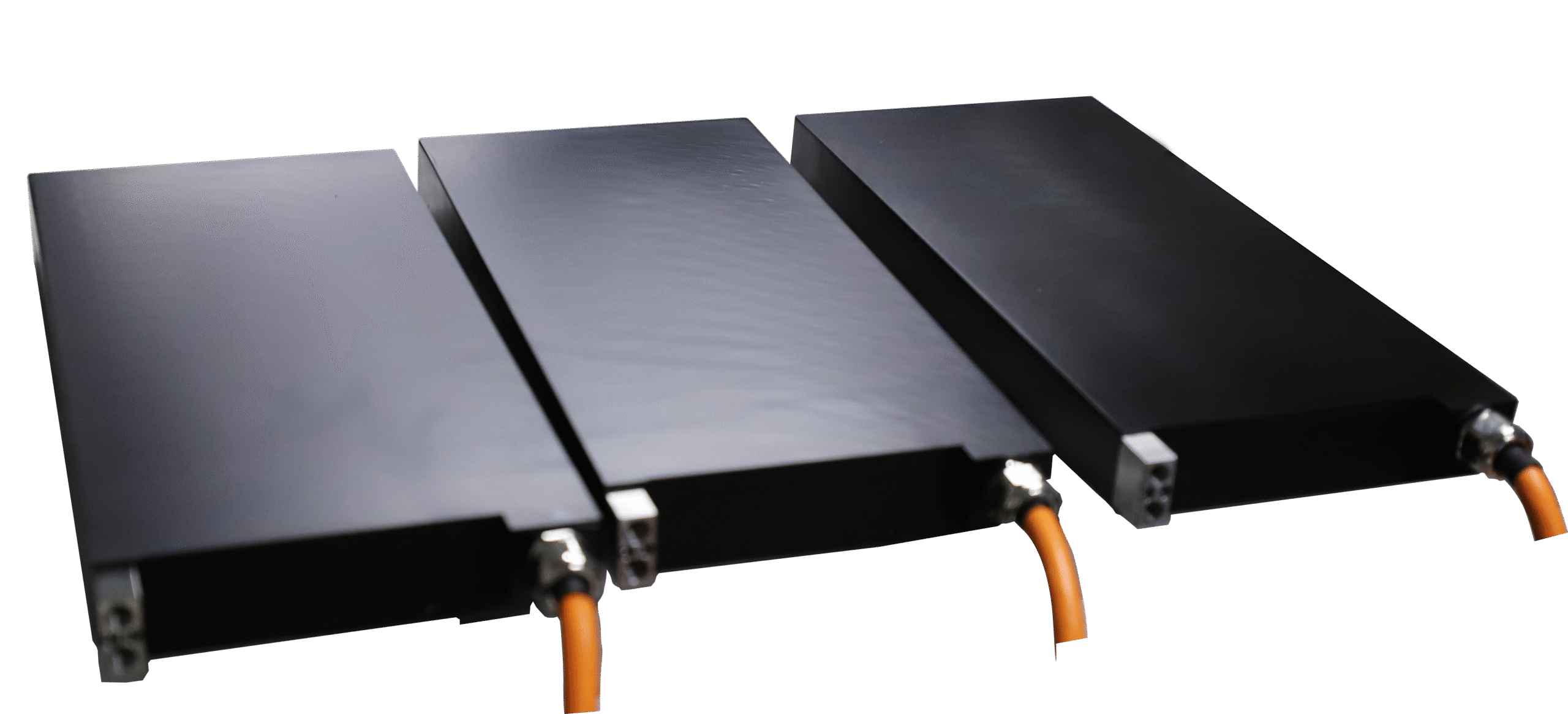

Semiconductor ironless lienar motor is also called carbon fiber board motor with feature high speed, high acceleration, high thrust density and efficient heat dissipation, enabling stable high-performance operation in semiconductor applications.

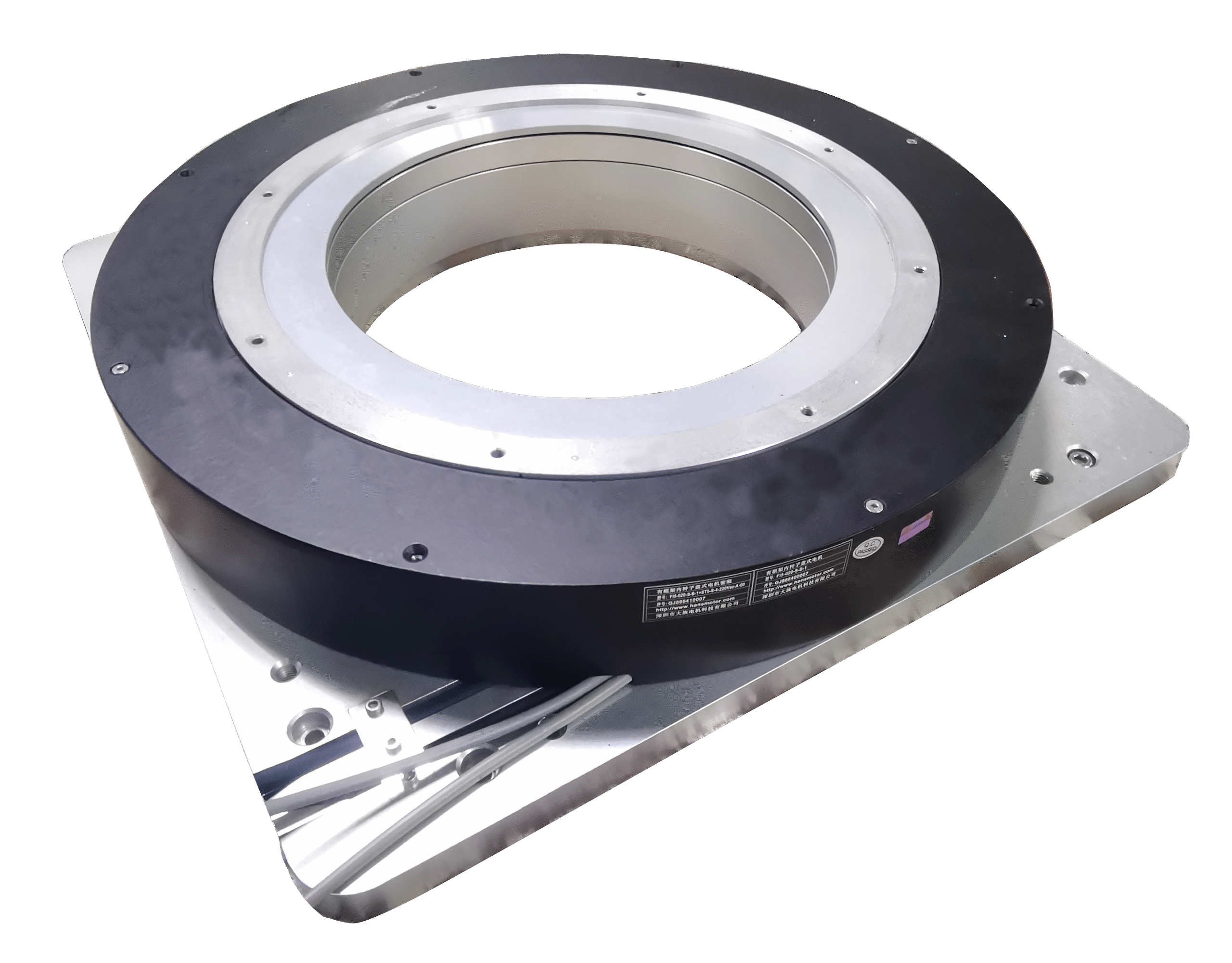

Features

FE3 Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

This linear motor is specially designed for semiconductor packaging equipment, featuring high precision, fast response, and stable performance to meet the demanding requirements of advanced packaging processes.

Features

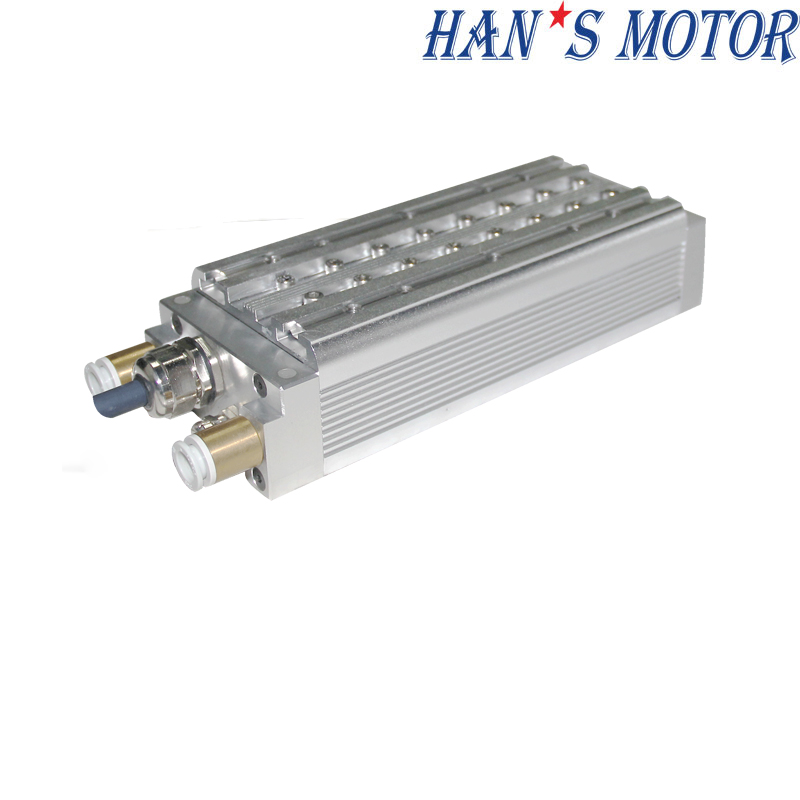

LSMFK series Water-Cooled Ironcore Linear Motors feature high thrust density 10000Nm and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

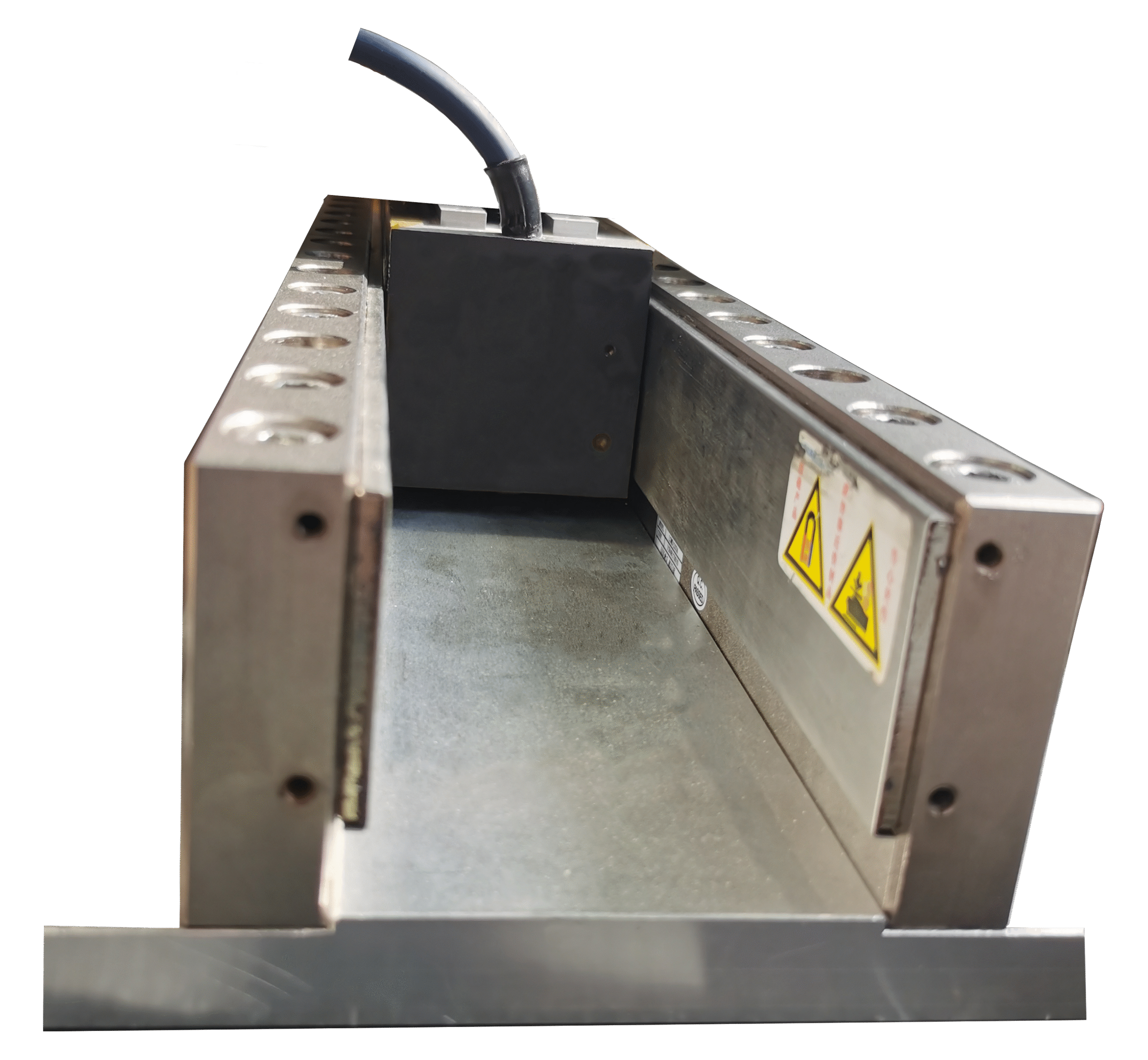

LSMD2 series double-sided magnet ironcore linear motor adopt gas cooling technology, high thrust with superior acceleration, cogging torque reduction technology, built-in thermal protection, and cancellation of unbalanced electromagnetic forces in demanding applications.