Products

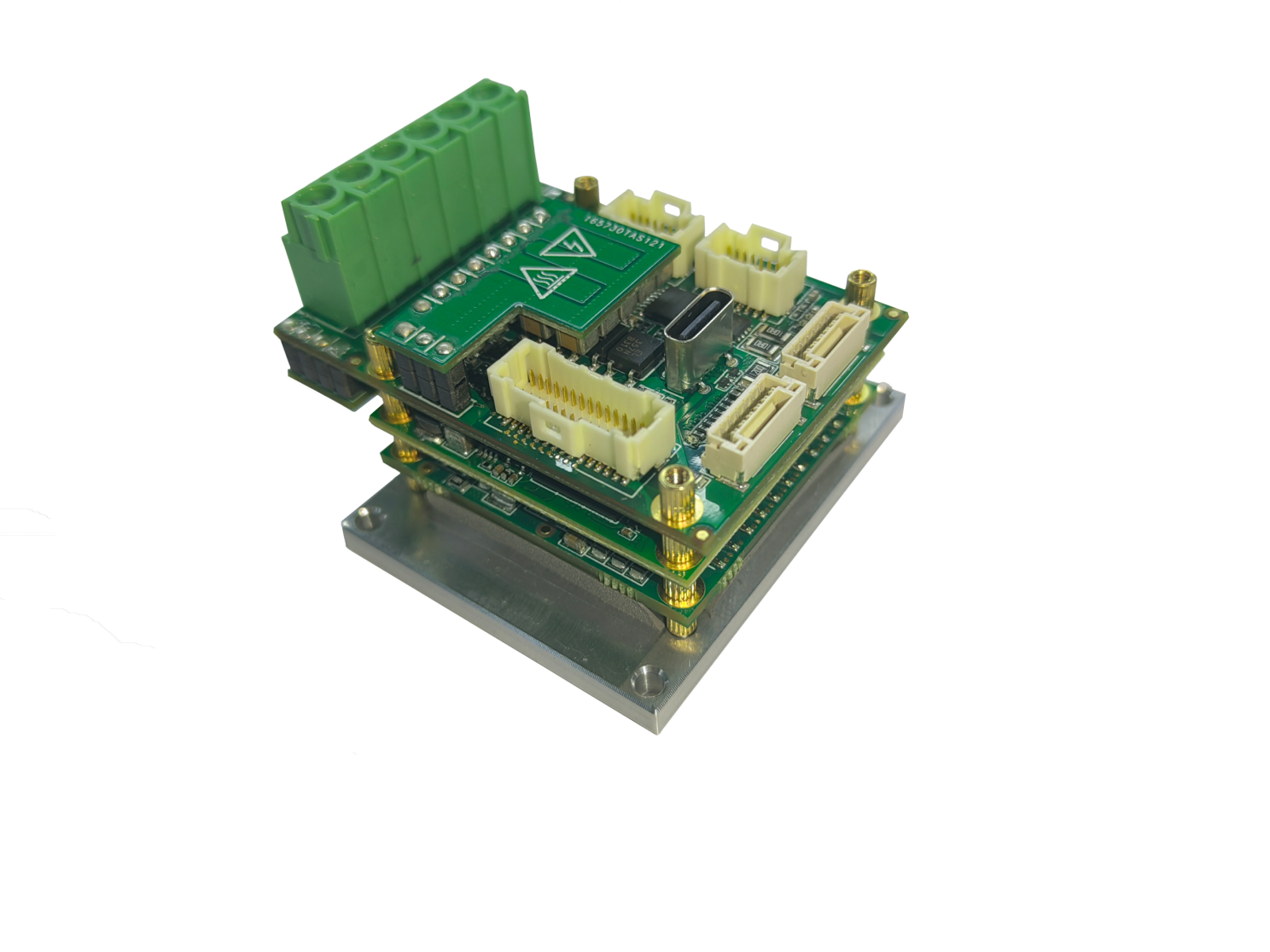

Micro DC Servo driver

The HX Micro DC Servo Driver delivers compact, high-performance motion control for robotics, AGVs, medical equipment, and automation systems.

It supports EtherCAT and CANopen communication, as well as A/B/Z incremental, Tamagawa absolute, and BISS-C encoder protocols.

Compatible with rotary servos, torque motors, linear motors, and voice coil motors, it ensures precise and reliable operation across diverse applications.

Brand:

Order(MOQ):

1

Product Detail

Feature:

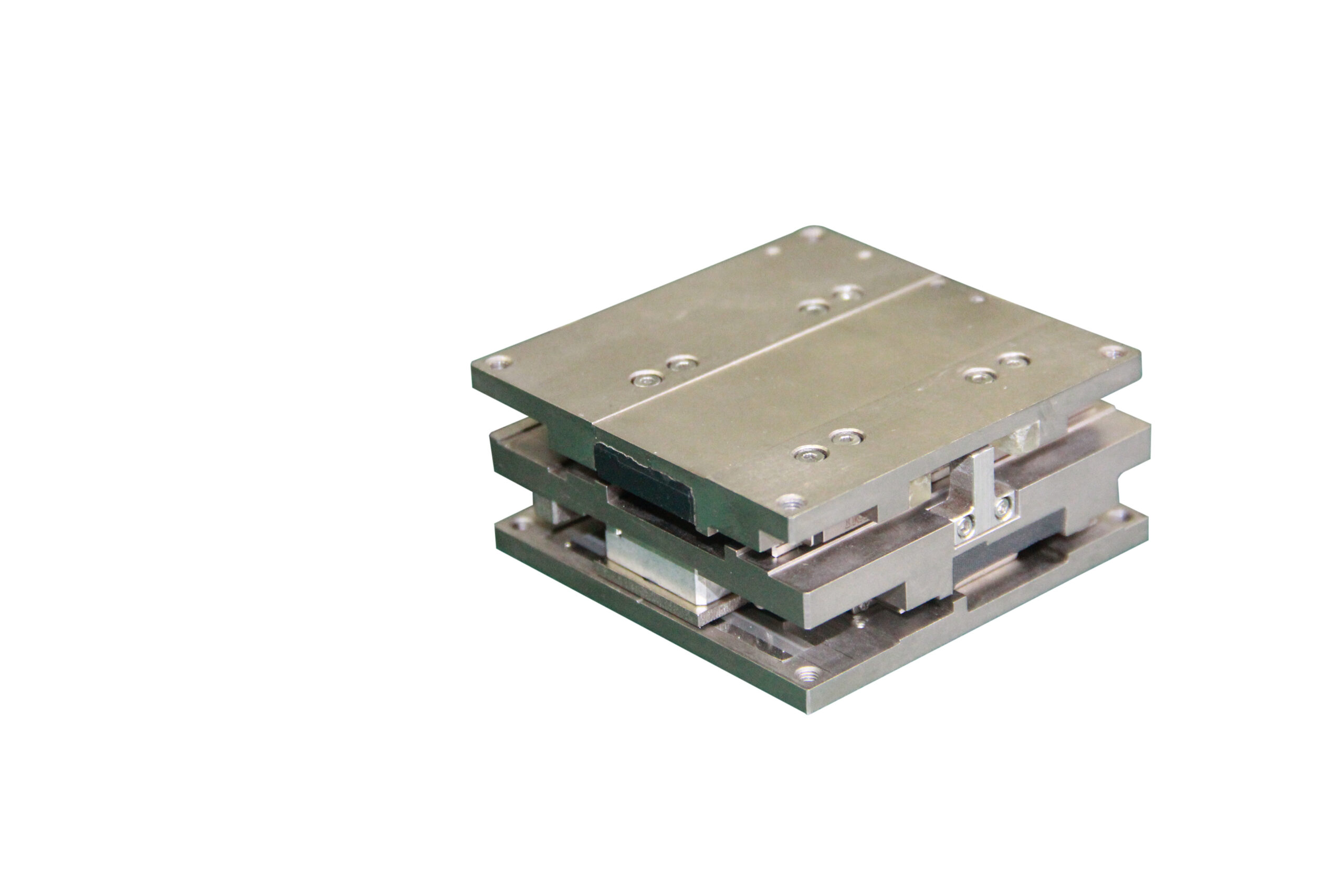

1. Compact & High-Power Design The HX Micro DC Servo Driver features advanced wide-bandgap semiconductors and hybrid analog-digital control, delivering ultra-high power density in a compact form for industrial automation.

2. Precise Closed-Loop Control Supports full closed-loop operation with digital A/B/Z optical encoders, eliminating positional deviations and ensuring accurate motion for robotics, AGVs, and medical equipment.

3. Flexible Integration & Motor Compatibility Compatible with rotary servos, torque motors, linear motors, and voice coil motors, and supports EtherCAT, CANopen, and multiple encoder protocols for seamless system integration.

Highlights:

·Ultra-compact design with leading power density

·Accurate motion control with full closed-loop operation

·Supports multiple motor types and industrial communication protocols

·Ideal for robotics, AGVs, medical devices, and semiconductor applications

Application:

Suitable for robotics, AGVs, medical equipment, and semiconductors.

Specification

| Item | HX-RC001D48 | HX-RC005D48 | HX-RC010D48 | HX-RC020D48 | HX-RC025D48 | HX-RC050D96 | HX-RC100D96 | |||

| Electrical parameter | Input voltage range | 14V-60VDC | 14V-96VDC | |||||||

| Rated output current Arms | 1 | 5 | 10 | 20 | 25 | |||||

| 50 | 100 | |||||||||

| Max. output current | 2.5 | 12.5 | 25 | 50 | 62.5 | |||||

| Arms | 125 | 250 | ||||||||

| Input/output signal | STO | 2 ways | ||||||||

| DI | 6 ways | |||||||||

| DO | 4 ways | |||||||||

| AI | 2 ways | |||||||||

| Communication interface | RS485、CANopen | |||||||||

| Motor feedback | Incremental ABZ, absolute BISS, absolute Tamagawa, rotary transformer | |||||||||

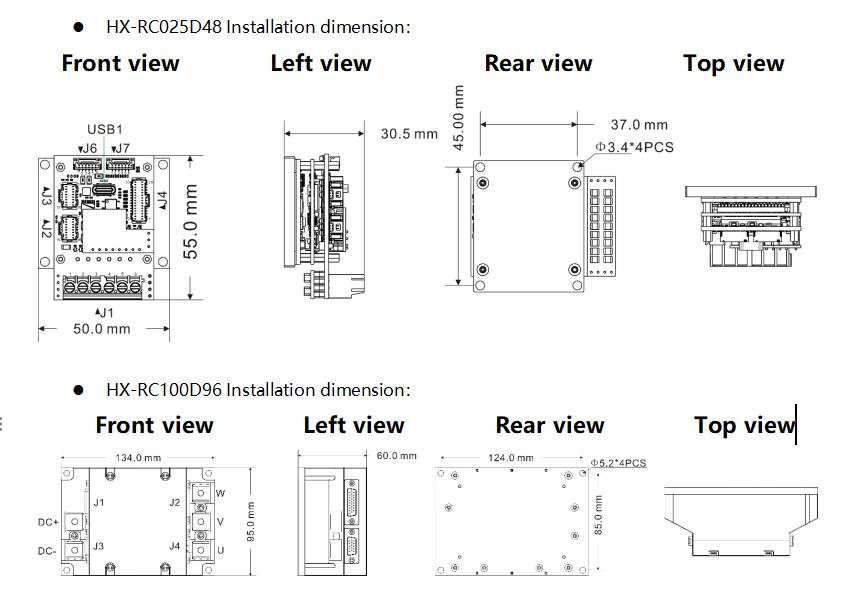

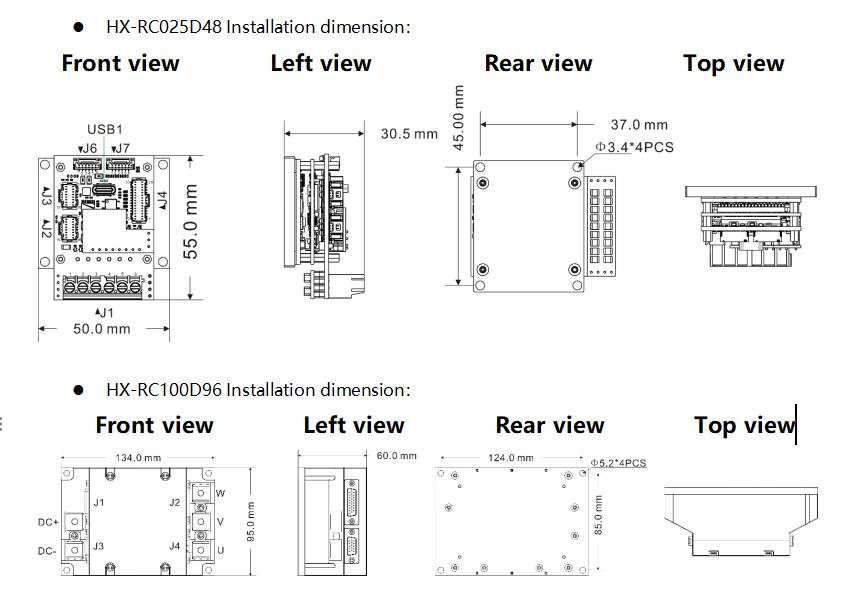

| Basic specification | Overall dimension | 50mm*55mm*32mm | 95mm*134mm*60mm | |||||||

| Conditions of use | Usage/storage temperature | -40~+55℃ / -40~+85℃ | ||||||||

| Usage/storage humidity | 90%RH (no condensation) | |||||||||

| Vibration/impact strength | 4.9m/s2 / 19.6m/s2 | |||||||||

| class of pollution | PD2 | |||||||||

| altitude | The highest altitude is 5000m. Derating is not required for use at 1000m or below. Derating is 1% for every 100m rise above 1000m. | |||||||||

| Built-in function | Protection function | Overcurrent, overvoltage, undervoltage, overload, gridlock, abnormal main circuit detection, heat sink overheating, excessive speed, encoder abnormal, parameter abnormal, etc. | ||||||||

| Debugging interface | USB | |||||||||

| Ease of use | Easy debugging interface, motor parameter setting, motor self-tuning, expert debugging, speed ring, position ring, current ring, motor tuning operation function, zero correction function (Angle identification), etc. | |||||||||

| Performance | Dynamic characteristics of current loop | Step response: 187.5us(0~100%) | ||||||||

| Frequency response: -3dB amplitude attenuation bandwidth, 2000Hz(command signal: ±25%); -90° phase shift bandwidth, 3500Hz(command signal: ±25%) | ||||||||||

| Speed control range | The speed ranges from 0 to 12000rpm. If the speed exceeds 6000rpm, contact the manufacturer. | |||||||||

| Dynamic characteristics of velocity loop | Step response: 562.5us(0~1000rpm) | |||||||||

| Frequency response: -3dB amplitude attenuation bandwidth, 1000Hz(command signal: ±500rpm); -90° phase shift bandwidth, 630Hz(command signal: ±500rpm) | ||||||||||

| Torque control accuracy | ±2% | |||||||||

Communication specification parameter

| Item | Description | ||

| Link layer protocol | CAN Bus | ||

| Application layer protocol | CANopen protoco | ||

| CAN-ID type | 11bit-CAN2.0A | ||

| Baud rate | 500Kbit/s | ||

| 1Mbit/s、250Kbit/s、125Kbit/s、100Kbit/s、50Kbit/s、20Kbit/s | |||

| Maximum number of sites | 63pcs | ||

| CAN frame length | 0~8bits | ||

| Application layer | Data frame, remote frame | ||

| CAN types | |||

| Terminal matching resistance | 120Ω | ||

| Support subprotocol | CiA-301V4.02:CANopen Application layer and communication protocol | ||

| DSP-402V3.0:Drive and motion control subprotocols | |||

| Support service | NMT:Network management system | ||

| SDO:Service data object | |||

| PDO:Procedure data object | |||

| Device monitoring: includes node protection and heartbeat | |||

| SYNC: Includes synchronization generator and synchronization receiver for PDO transmission | |||

| PDO transmission type | Time trigger, event trigger, synchronization trigger | ||

| Supported PDO Number | 4 RPDO,4 TPDO | ||

| SDO transfer mode | Accelerate SDO transmission | ||

| Support servo operation mode | profile position mode | ||

| profile speed mode | |||

| profile torque mode | |||

| homing mode | |||

| Interpolated Position Mode | |||

Installation Dimensions

Sample

Contact Us

Experience our expert support, tailored solutions, and reliable global delivery.

Related Products

Features

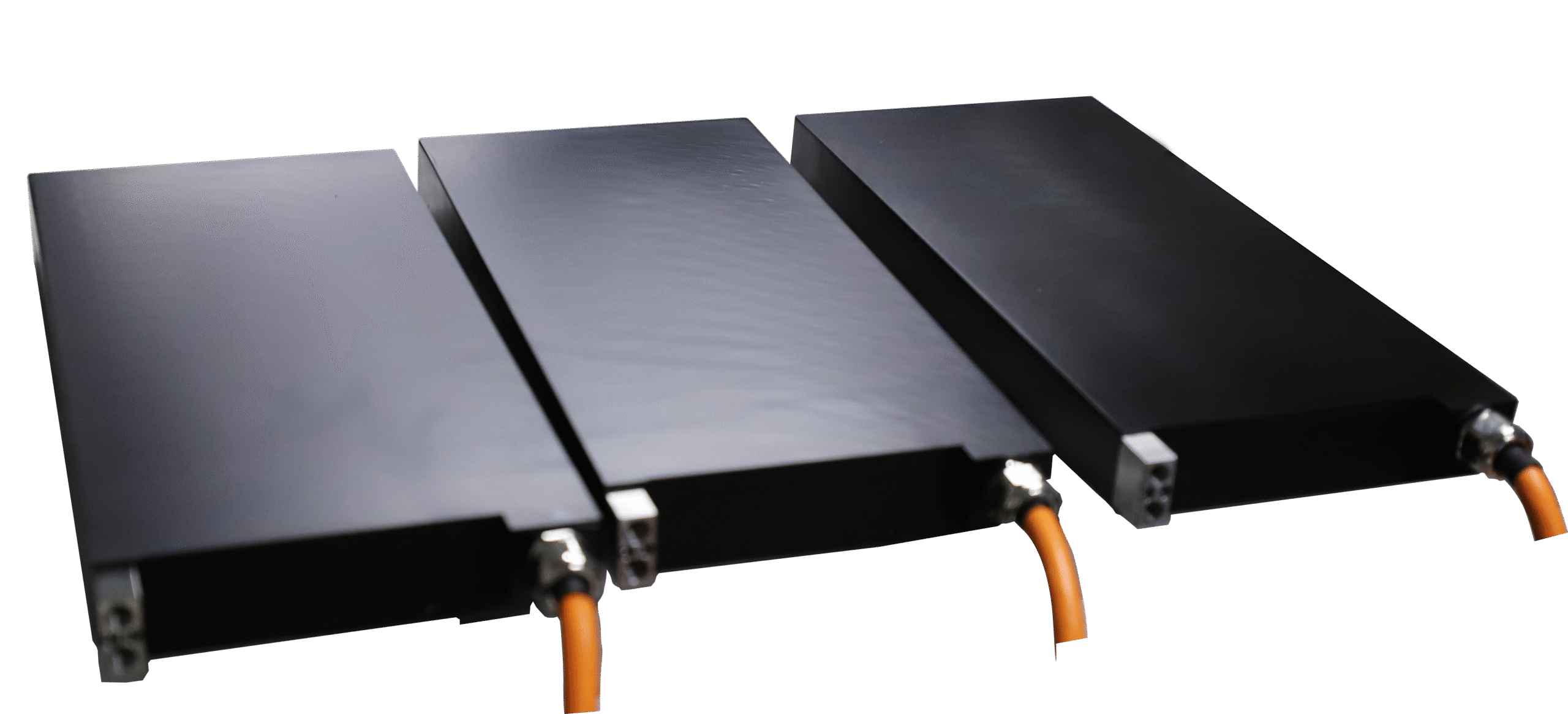

Semiconductor ironless lienar motor is also called carbon fiber board motor with feature high speed, high acceleration, high thrust density and efficient heat dissipation, enabling stable high-performance operation in semiconductor applications.

Features

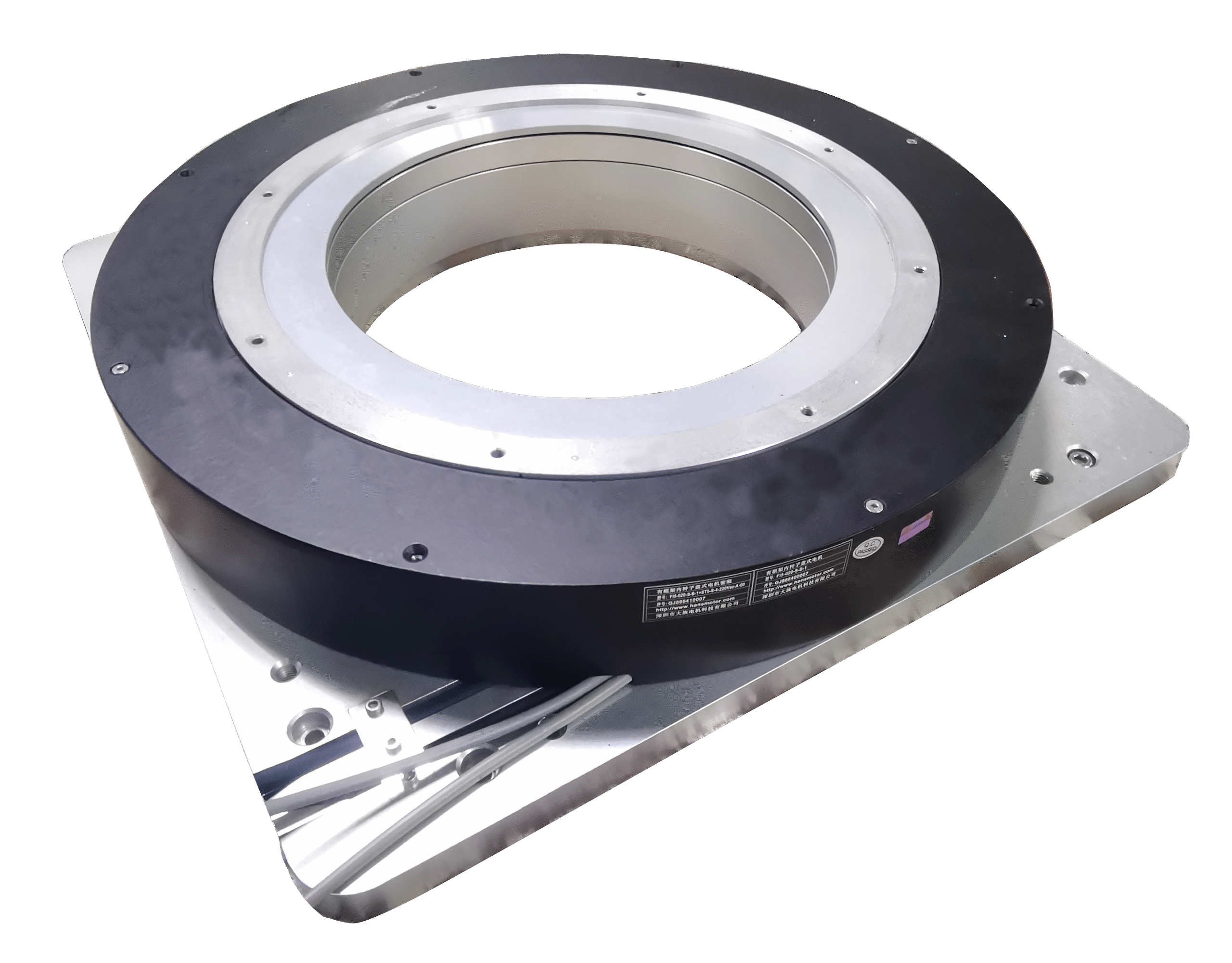

FE3 Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

This linear motor is specially designed for semiconductor packaging equipment, featuring high precision, fast response, and stable performance to meet the demanding requirements of advanced packaging processes.

Features

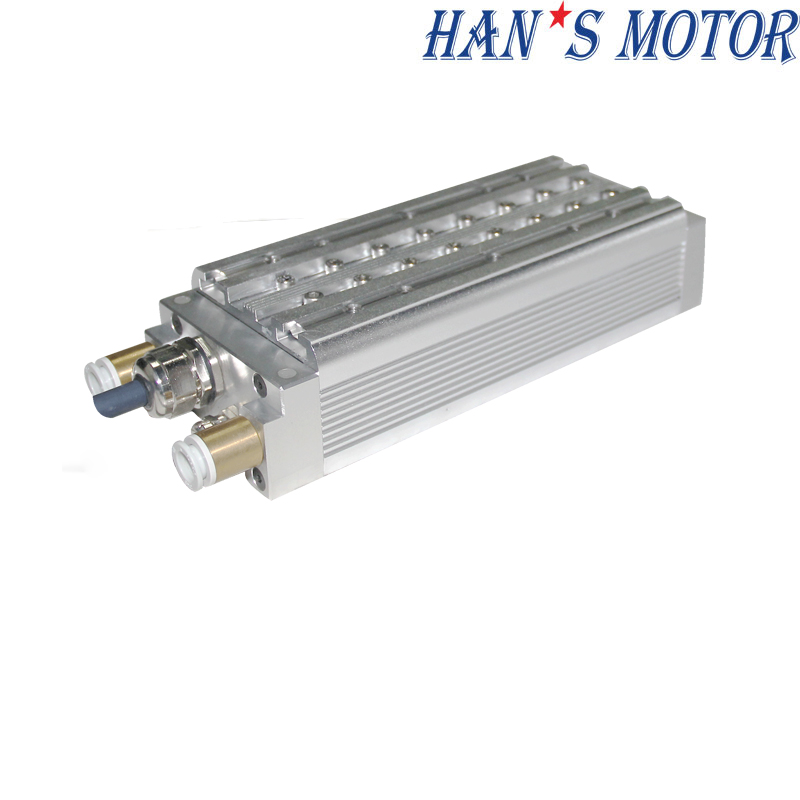

LSMFK series Water-Cooled Ironcore Linear Motors feature high thrust density 10000Nm and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

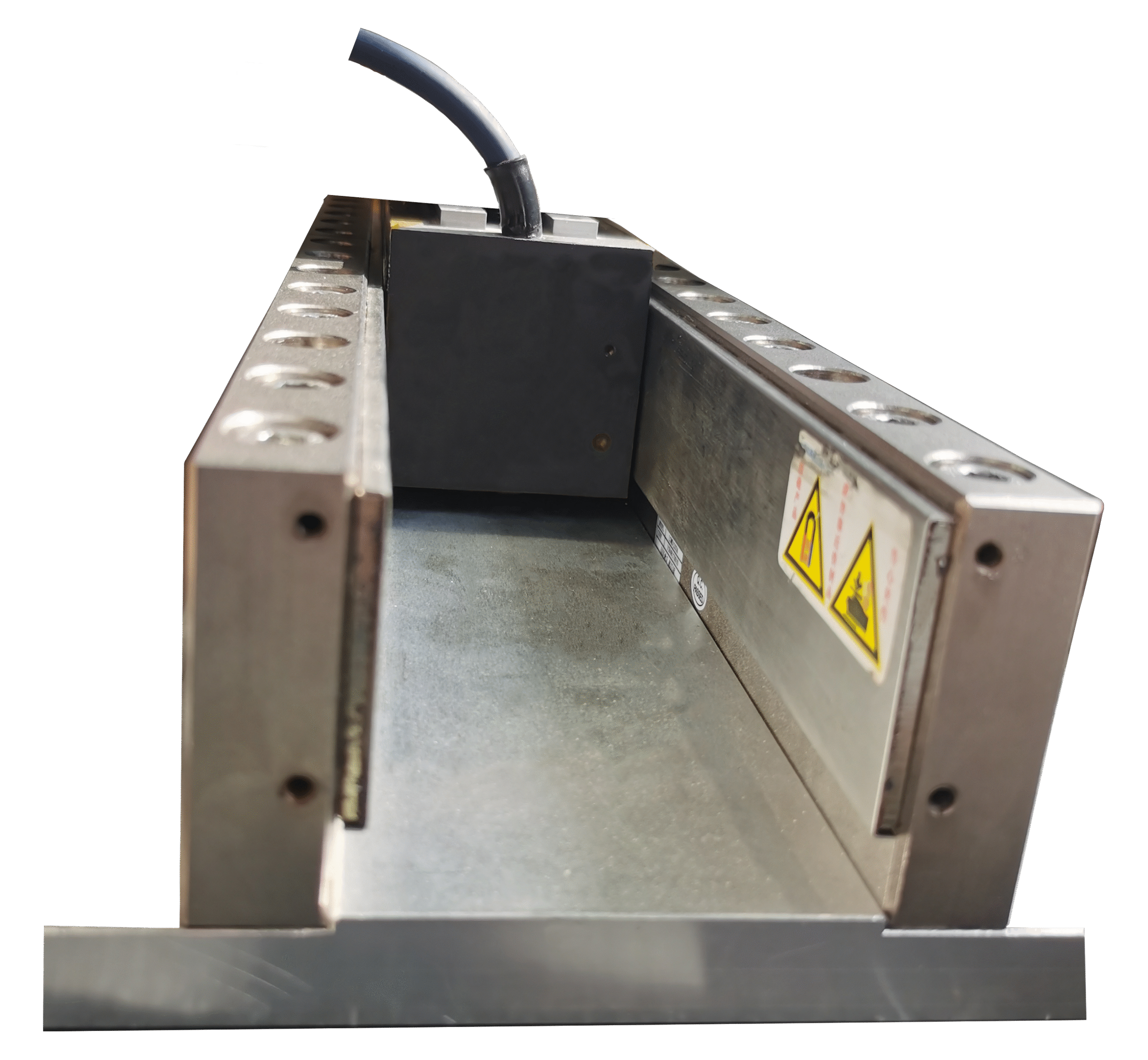

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

LSMD2 series double-sided magnet ironcore linear motor adopt gas cooling technology, high thrust with superior acceleration, cogging torque reduction technology, built-in thermal protection, and cancellation of unbalanced electromagnetic forces in demanding applications.