Products

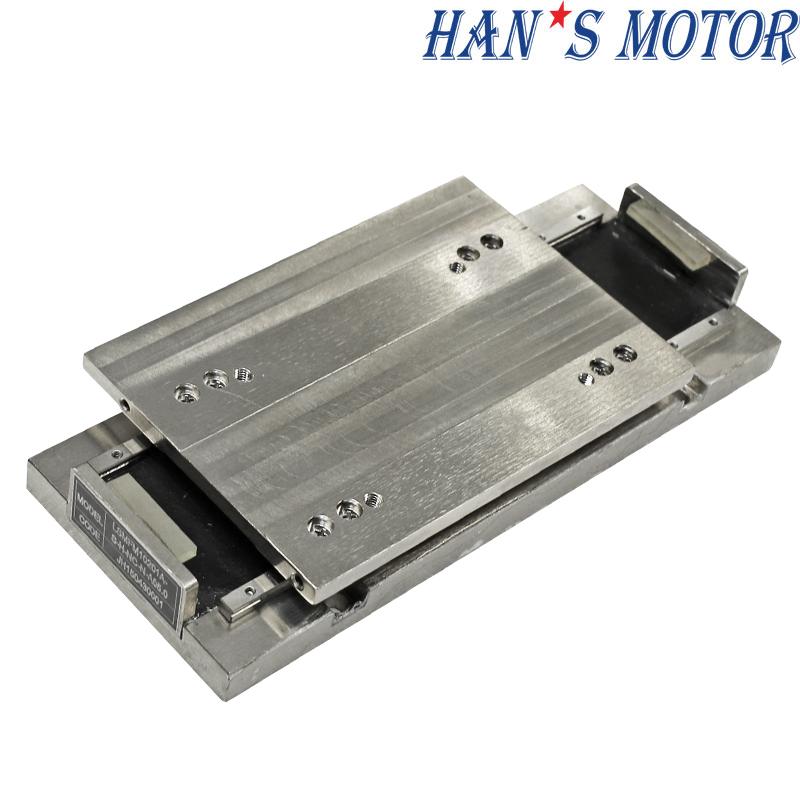

Automatic Linear Motion Stage

This single-axis linear motion stage is tailored for automated robotic platforms. It delivers smooth movement with high repeatability through precision motor control. Its modular frame supports different mounting orientations and load requirements. Suitable for electronics, packaging, and lab automation. Easy to integrate and maintain in continuous-use environments.

Brand:

Order(MOQ):

1

Product Detail

Product Specifications

Motor Model/Parameter

| Motor Parameters | ||

| Unit | Data | |

| Continuous Force (Tmax) | N | 8 |

| Peak Force | N | 32 |

| Motor Constant | N√W | 1.74 |

| Max.Continuous Power Dissipation | W | 21.1 |

| Continuous Current (Tmax) | Arms | 0.8 |

| Peak Current (1S) | Arms | 3.2 |

| Force Constant (25℃,±5%) | N/Arms | 10 |

| Back EMF Constant (25℃,±5%) | Vrms/m/s | 3.3 |

| Electrical Resistance(25℃,±5%)P-P | Ω | 15.7 |

| Inductance(25℃,±20%)P-P | μm | 0.43 |

| Max Coil Temperature | ℃ | 120 |

| Polar Distance (N-N) (360℃ Electrical cycle) | mm | 36 |

| Magnetic Attraction | N | 84 |

| Stator Mass (glue+solder-covered wire) | kg | 0.14 |

| Mover Mass (magnetic) | kg/M | 0.9 |

| Stage Parameters | ||

| Unit | Data | |

| Max. Load | kg | 3.5 |

| Effective Stroke | mm | 25 |

| Resolution | μm | 0.1 |

| Max.Speed (1) | mm/s | 700 |

| Repeat accuracy | μm | ±0.5 |

| Weight | kg | 0.5 |

| Working environment temperature and humidity | 0-40℃、20-80%RH | |

Note (1): According to the actual load, the maximum speed maybe cannot be reached,

so the specific speed should be communicated with the engineer

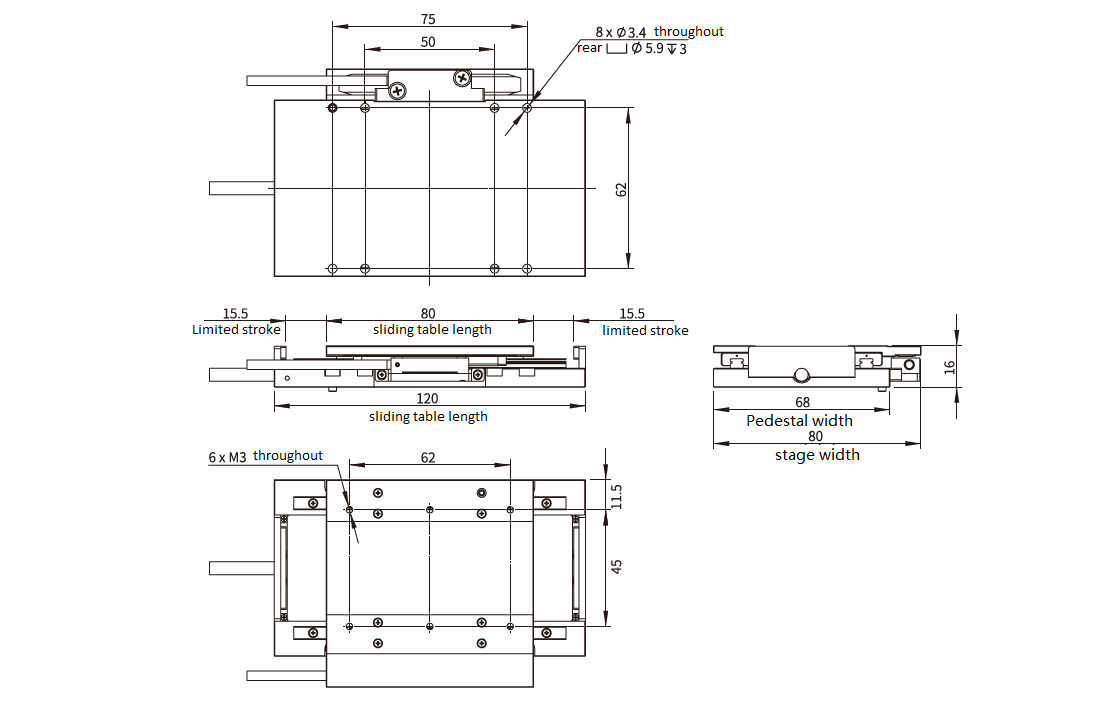

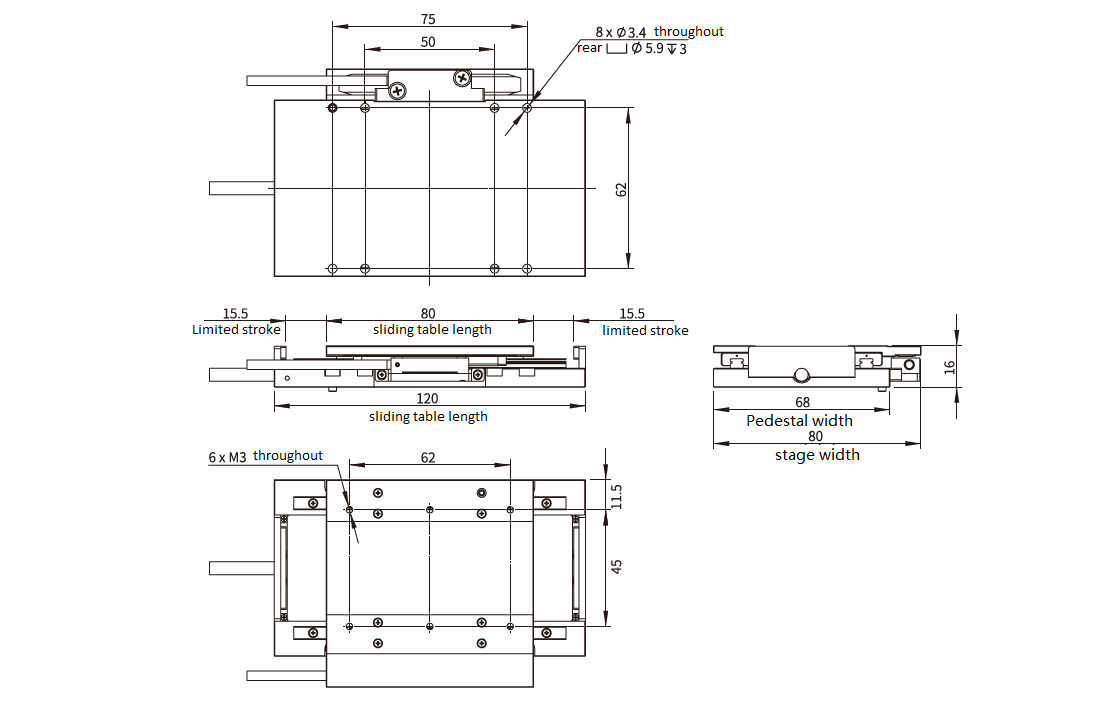

Dimension

Characteristics:

1.Provide controlled horizontal motion for automated machines.

2.Typically mounted on ball bearings or roller slides and are available with a variety of linear bases.

3.Dynamic and static friction resistance, which is helpful to improve the response speed and sensitivity of CNC system.

4.The driving power is small which reduces the energy consumption.

5.Lightweight, easy to use, easy for maintenance.

Why choose us?

Q1: Are you trading company or manufacturer?

A: We’re integrated company with R&D and production base.

Q2: How long is your delivery time and shipment?

Sample leading-time: Generally 10 workdays

Production leading-time: 26 workdays

Delivery time: 15-20 days after confirmed order according to production season and order quantity.

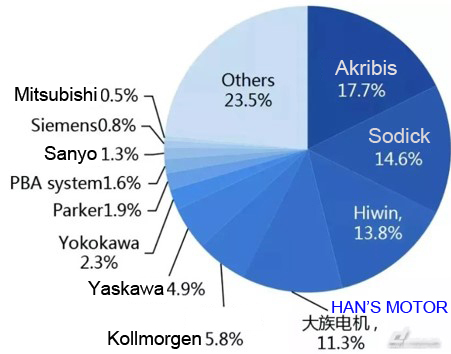

Q3: What is your advantage?

Competitive price and high quality with technical engineers for aftersales service and quick delivery.

Achievements as national “Specialized Refinement Differential Innovation” Enterprise

for the leader of linear motor market share.

Warranty Statement:

Integration of production and marketing that provided you with affordable price.

The warranty period is 12 months since you receive the goods.

Standard samples will be delivered within 15 days and customized samples will be delivered within 31 days.

Delivery date for bulk order depends on order quantity.

Applications:

1.Laser industry: laser cutting machine, laser engraving machine, laser machine and so on;

2. Electronic machinery: semiconductor machinery, mechanical arm, sliding platform, measuring machine, SMT equipment, etc.

3.Industrial machinery: plastic machinery, printing machinery, paper machinery, textile machinery, food machinery, etc.

HAN’S Motor Motion Stages Products Series:

Packaging & Delivery:

Packaging Details.: plywood packing

Port.: Shenzhen ( Sea / Air shipping, TNT, UPS, FedEx and DHL ect.)

Leading time: According to the order quantity, 10 days for the small order and 20 days for the bulk order

Sample

Contact Us

Experience our expert support, tailored solutions, and reliable global delivery.

Related Products

Features

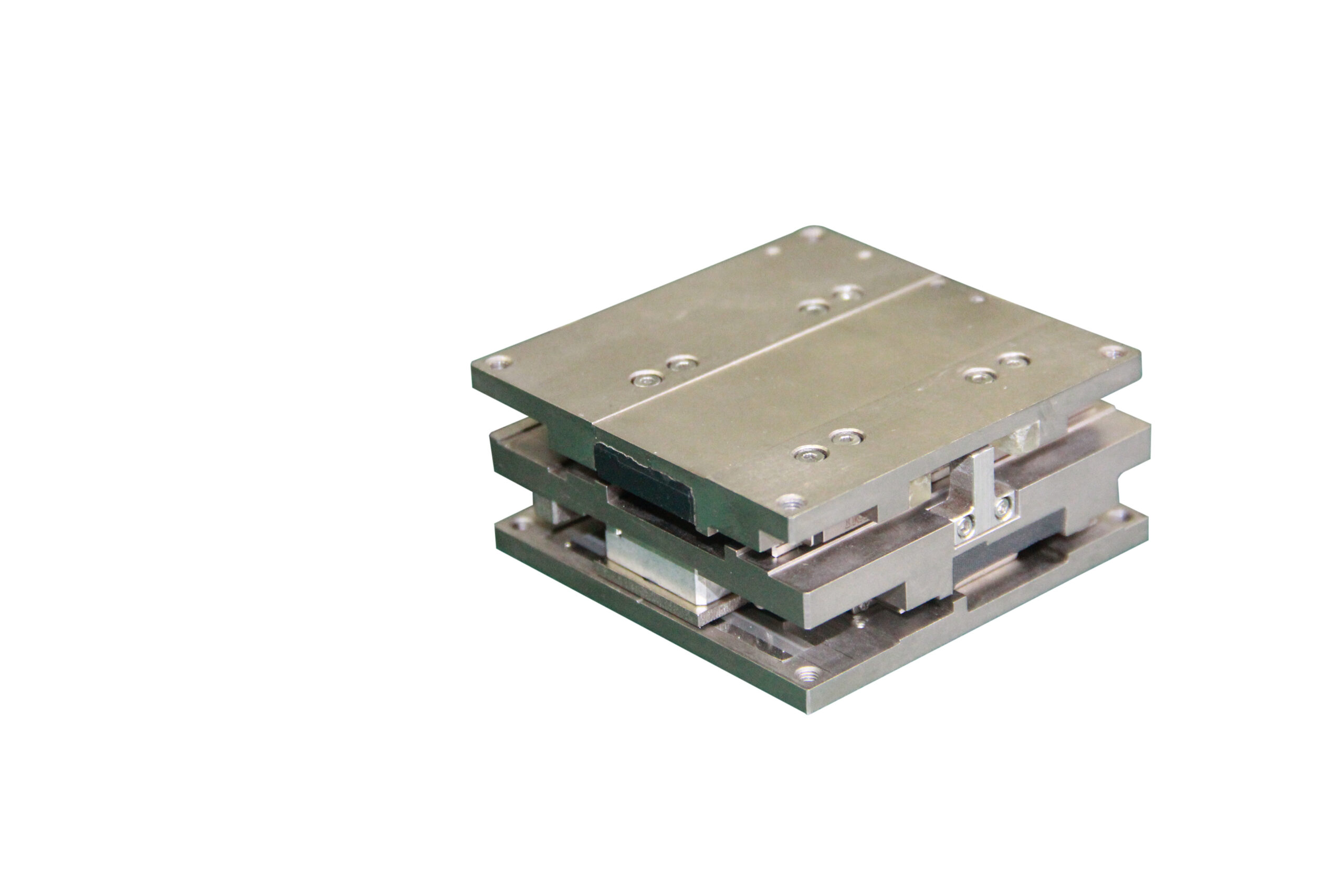

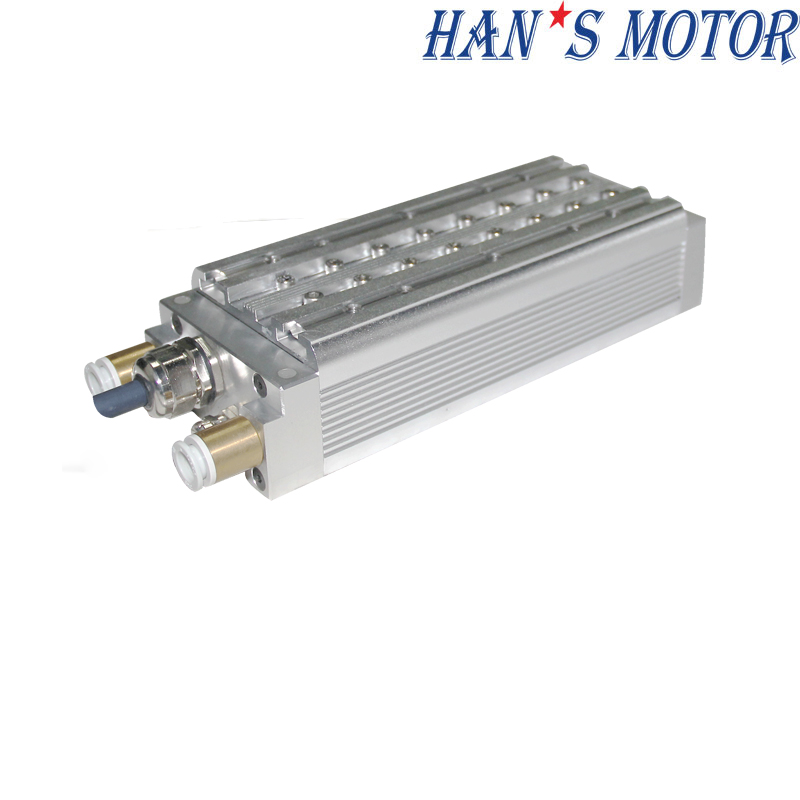

Semiconductor ironless lienar motor is also called carbon fiber board motor with feature high speed, high acceleration, high thrust density and efficient heat dissipation, enabling stable high-performance operation in semiconductor applications.

Features

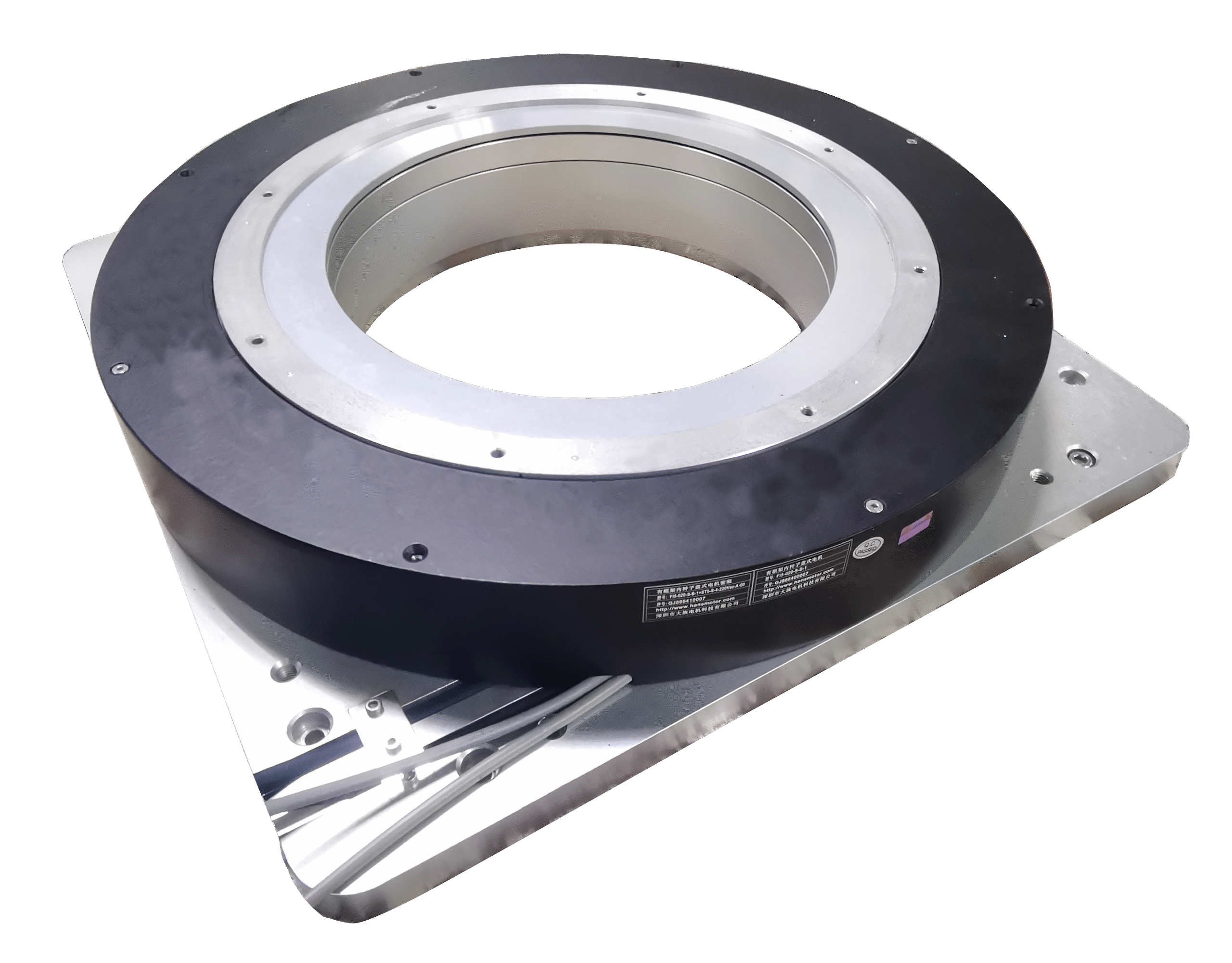

FE3 Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

This linear motor is specially designed for semiconductor packaging equipment, featuring high precision, fast response, and stable performance to meet the demanding requirements of advanced packaging processes.

Features

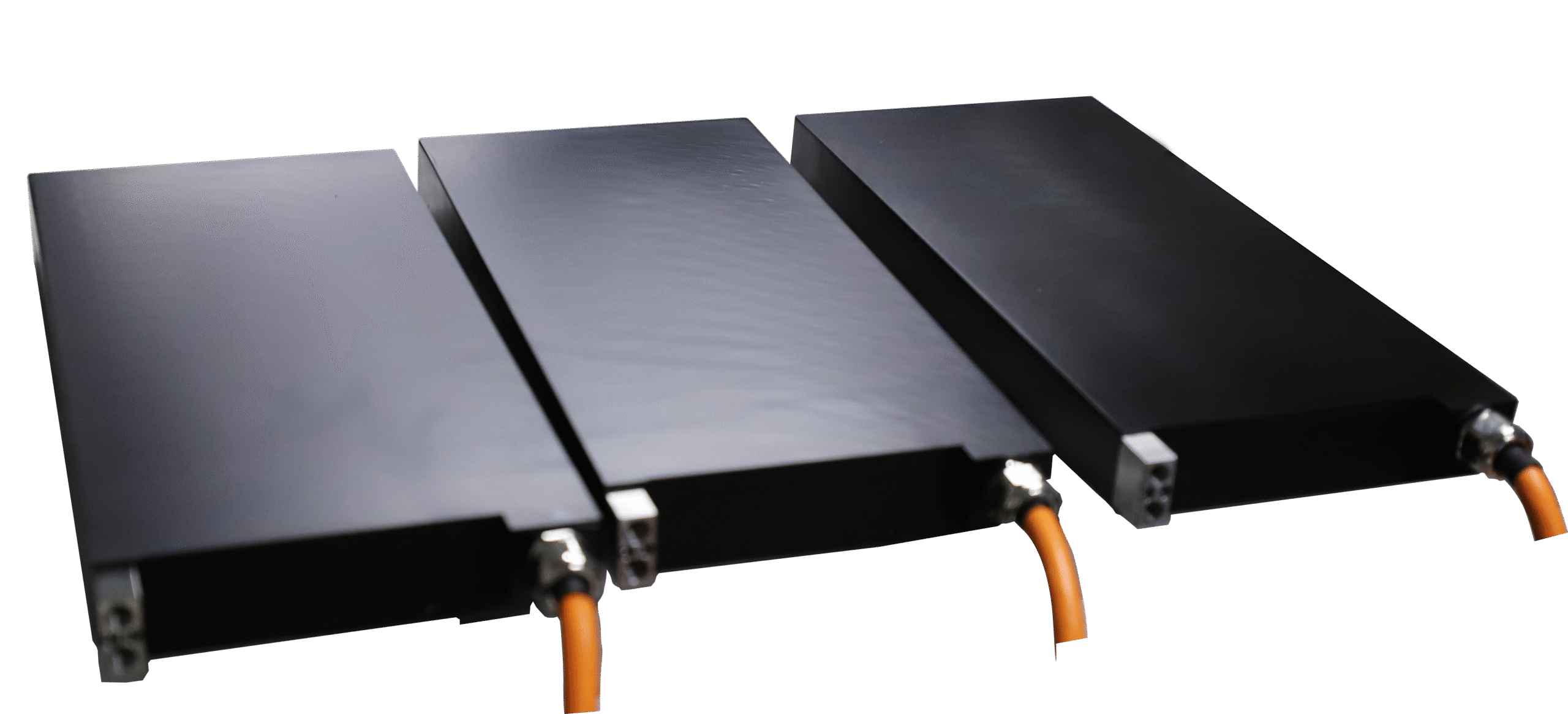

LSMFK series Water-Cooled Ironcore Linear Motors feature high thrust density 10000Nm and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

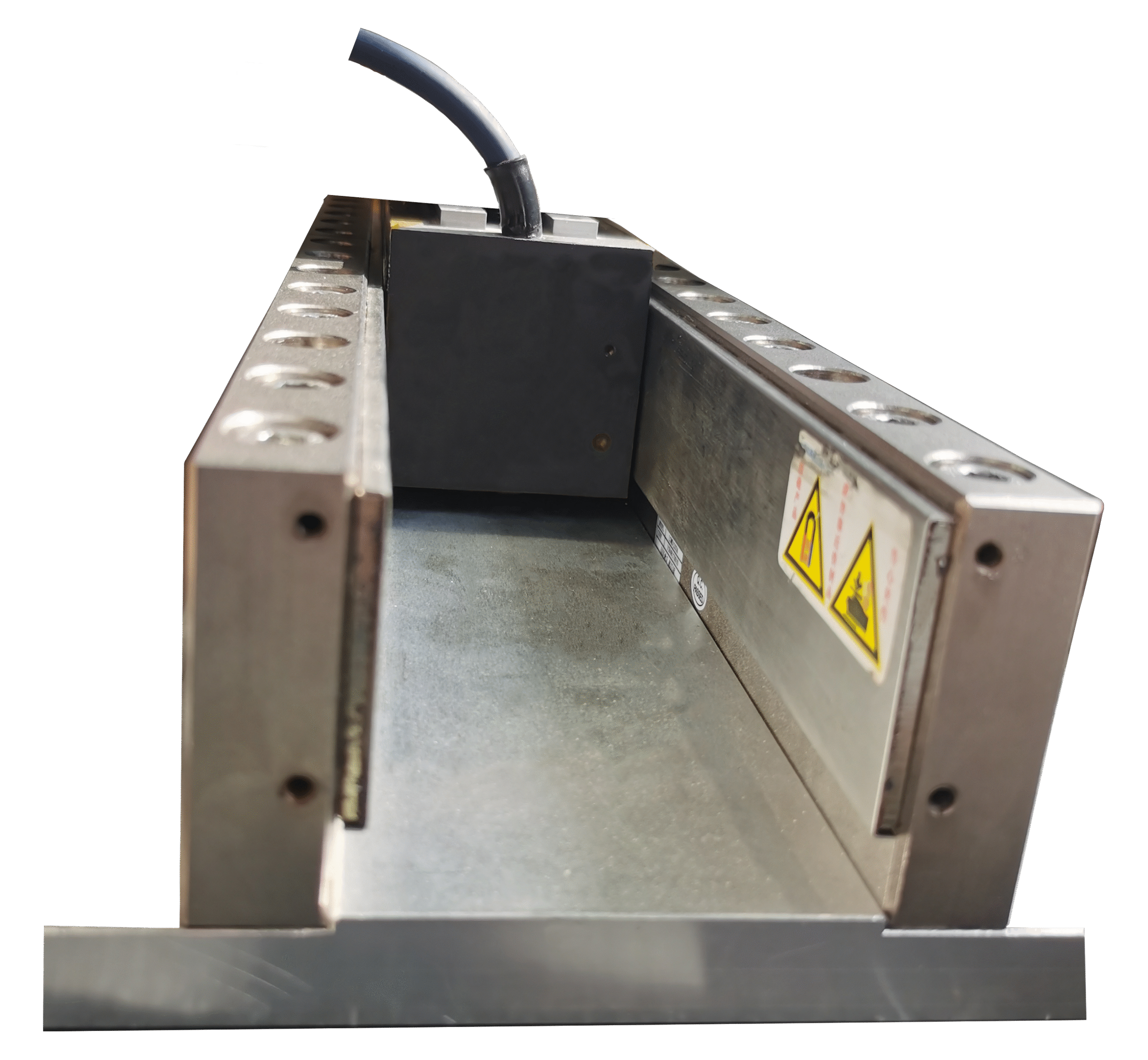

LSMD2 series double-sided magnet ironcore linear motor adopt gas cooling technology, high thrust with superior acceleration, cogging torque reduction technology, built-in thermal protection, and cancellation of unbalanced electromagnetic forces in demanding applications.