Products

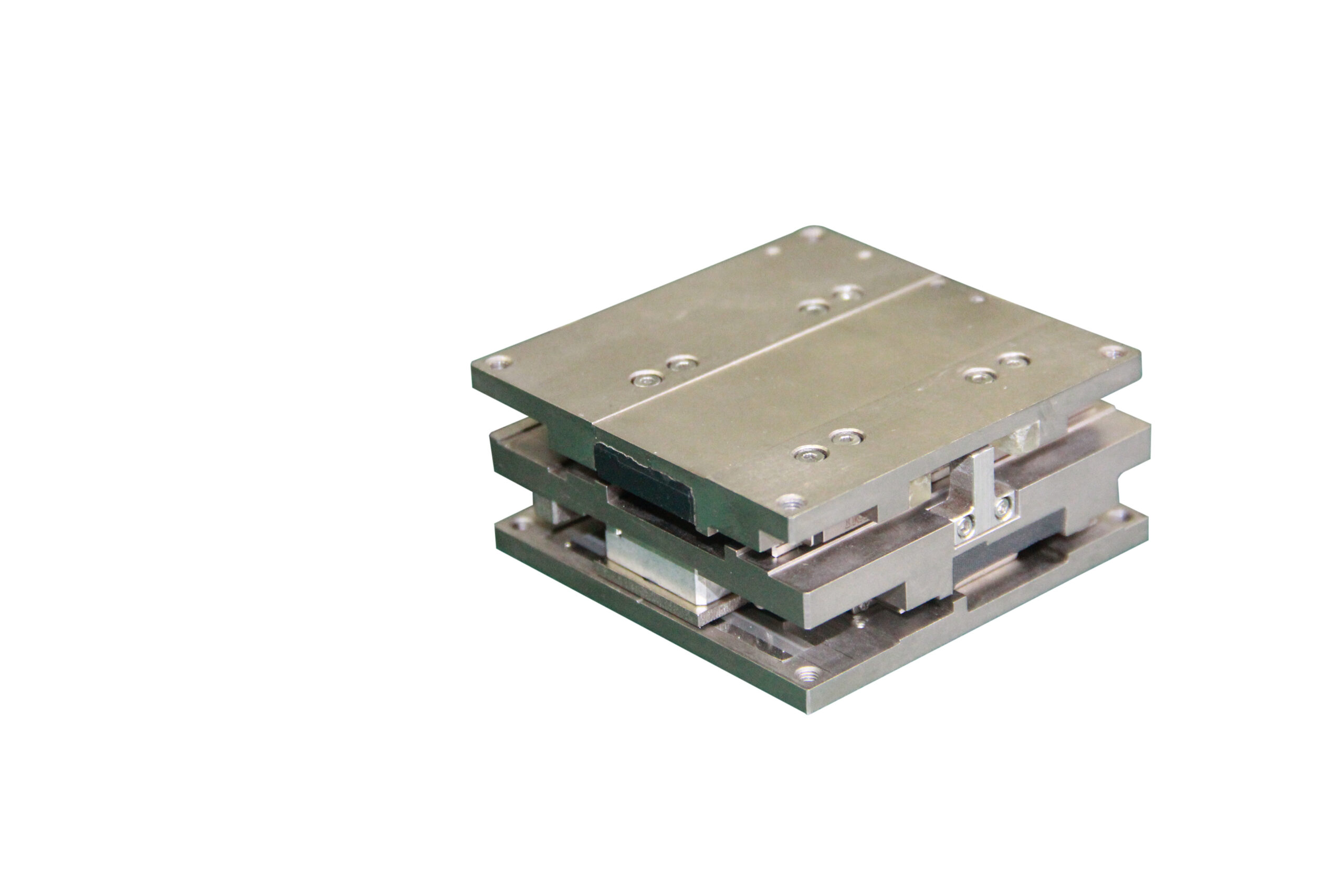

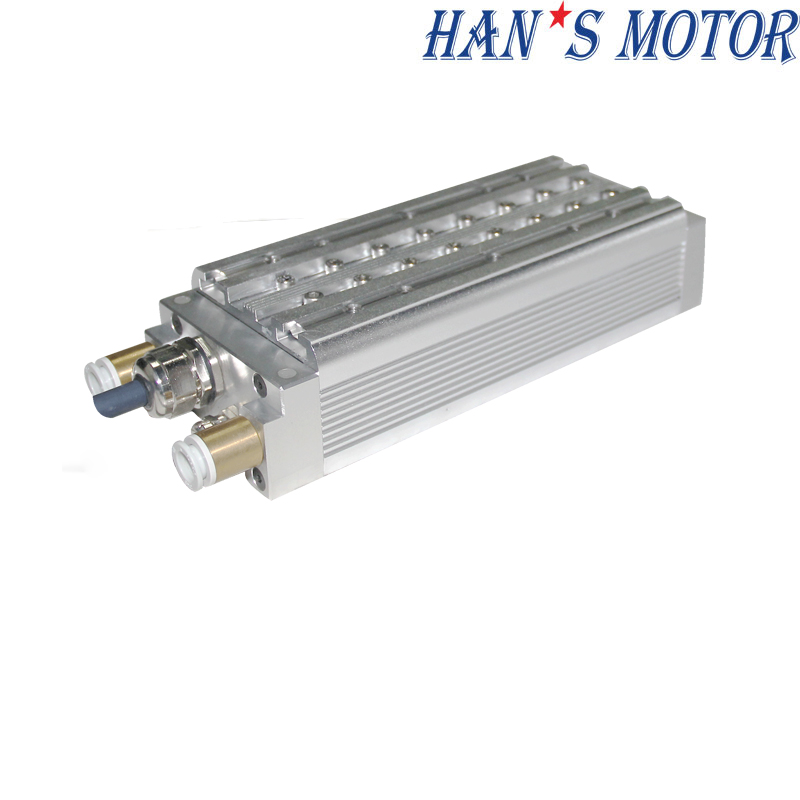

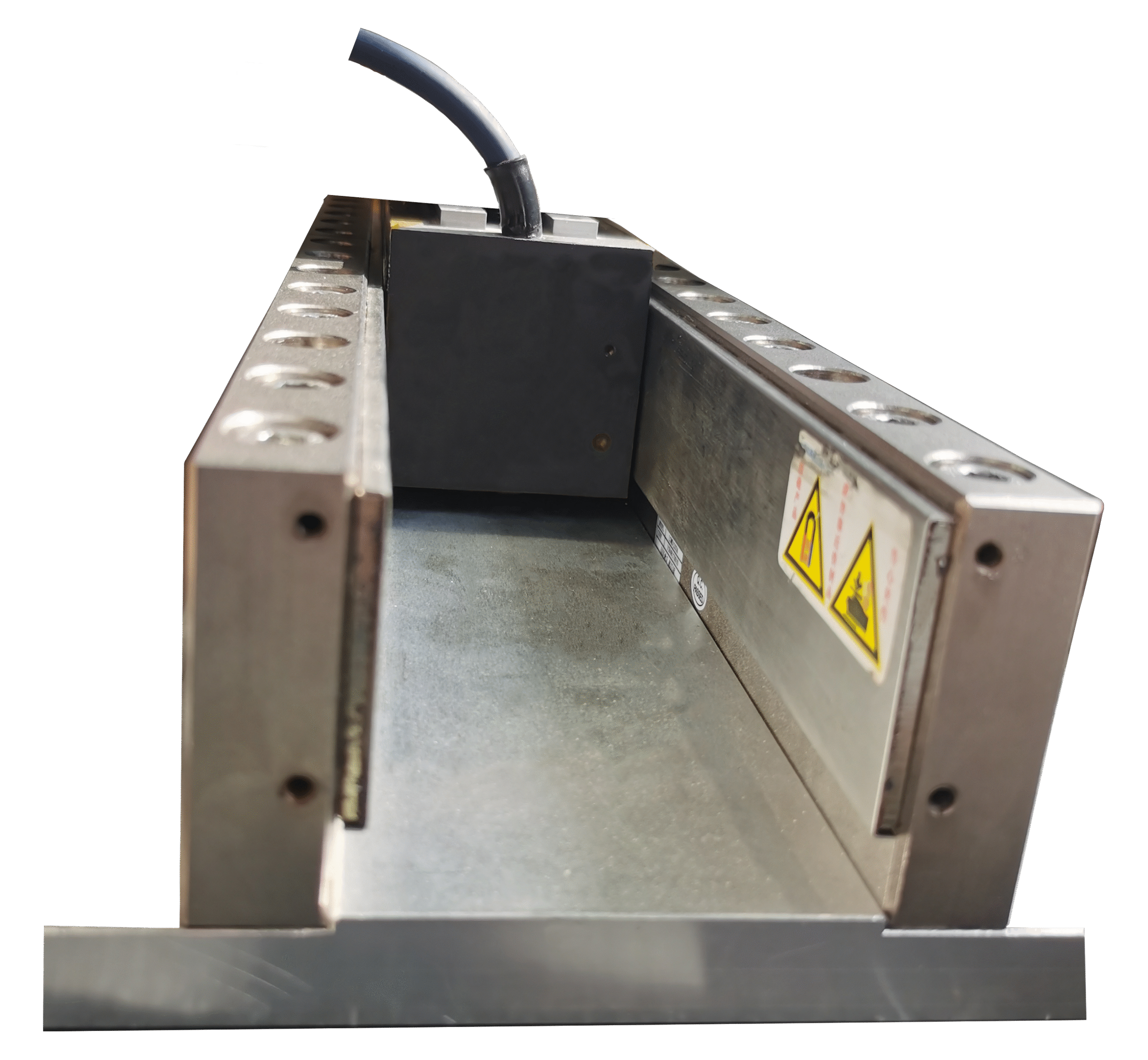

Miniature Linear Motion Stage

This compact linear motion stage provides precise control in a small footprint. Featuring a linear guide system, it enables high-resolution positioning for industrial-grade applications. Ideal for precision machinery and space-limited automation scenarios.

Brand:

Order(MOQ):

1

Product Detail

Product Specifications

Motor Model/Parameter

| Motor Parameters | ||

| Performance | Unit | Data |

| Continuous Force (Tmax) | N | 15 |

| Peak Force | N | 150 |

| Max. Load | kg | 5 |

| Effective Stroke | mm | 200 |

| Resolution | μm | 0.1 |

| Max.Speed | mm/s | 700 |

| Repeat accuracy | μm | ±0.6 |

| Weight | kg | 3.5 |

| Working environment temperature and humidity | 0-40℃、20-80%RH | |

Performance

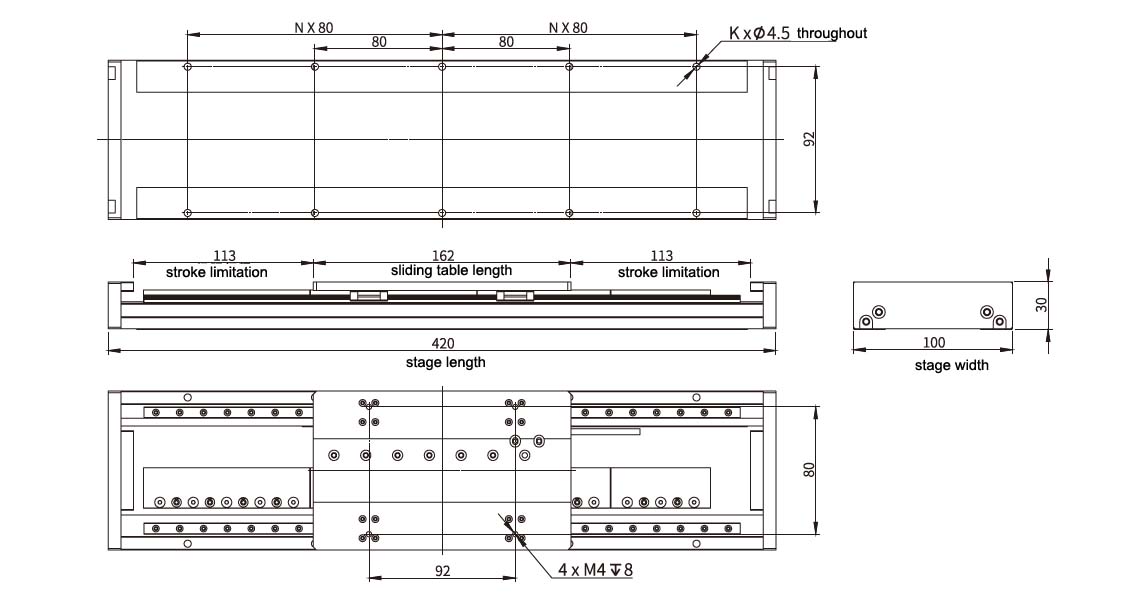

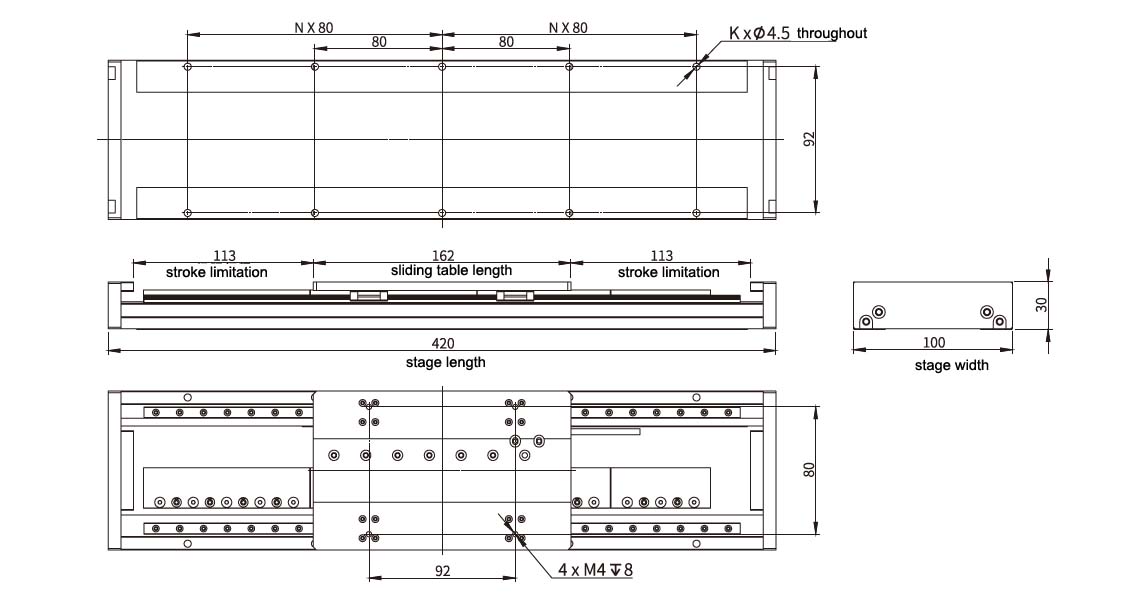

| Parameter\ Stroke (mm) | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 |

| K | 6 | 10 | 14 | 14 | 18 | 18 | 22 | 26 | 26 | 30 | 34 | 34 |

| N | 1 | 2 | 3 | 3 | 4 | 4 | 5 | 6 | 6 | 7 | 8 | 8 |

| Stage Total Length (mm) | 320 | 420 | 520 | 620 | 720 | 820 | 920 | 1020 | 1120 | 1220 | 1320 | 1420 |

Note (1): According to the actual load, the maximum speed maybe cannot be reached,

so the specific speed should be communicated with the engineer

Dimension

Characteristics:

1. Adopt high rigidity aluminum profile, truly achieve high speed mechanical production efficiency, high positioning accuracy and repeat positioning accuracy.

2. With self-developed integrated guideway design, improved rigidity, straightness, and flatness leads to higher performance in applications: machinery manufacturing, electronics, semiconductors, optoelectronic,medical treatment, construction, factory automation and other fields.

3. High reliability, smooth operation, high Rigidity & Preload High durability, easy to install and maintenance and low cost.

Why choose us?

Q1. Are you the direct manufacturer or a trade company?

A: We are a manufacturer. All of our products are manufactured in Shenzhen plant.

Q2. What is advantage of your company?

A : Comprehensive modern high-tech enterprise with the integration of R&D, manufacture, sales and service.

Q3. How can we trust your company?

A: 100% direct supplier allows for maximized profits for clients.

100% excellent quality guaranteed where each production process is strictly controlled.

100% on-time delivery, approximately 19 years of professional production and installation.

Q4. Can you give warranty of your products?

A: All products are inspected for quality before shipment, materials and applications need to be able to work continuously through extremely harsh working environments.

Q5. What is the MOQ?

A: We need to discuss more details for customization, description of the products you want, such as size, material, quantity and so on. High quality and competitive price are always provided.

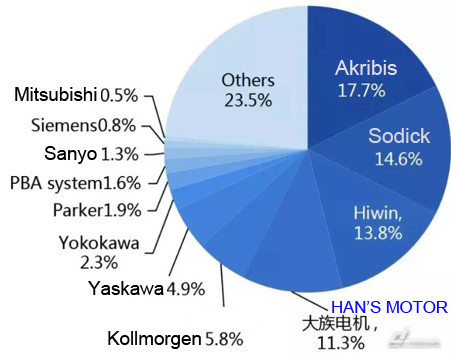

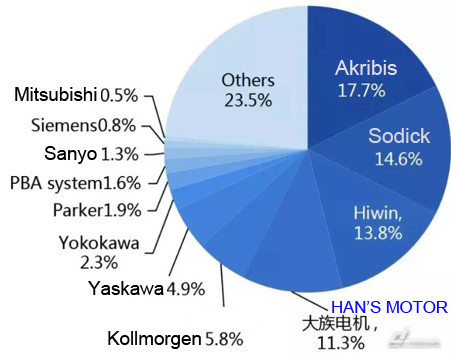

Achievements as national “Specialized Refinement Differential Innovation” Enterprise

for the leader of linear motor market share.

Applications:

Automatic production lines, medical equipment, laser cutting equipment, spray machine equipment, dispenser, chip mounter, 3D printing machine etc.

HAN’S Motor Motion Stages Products Series:

Packaging & Delivery:

Packaging Details.: plywood packing

Port.: Shenzhen ( Sea / Air shipping, TNT, UPS, FedEx and DHL ect.)

Leading time: According to the order quantity, 10 days for the small order and 20 days for the bulk order

Sample

Contact Us

Experience our expert support, tailored solutions, and reliable global delivery.

Related Products

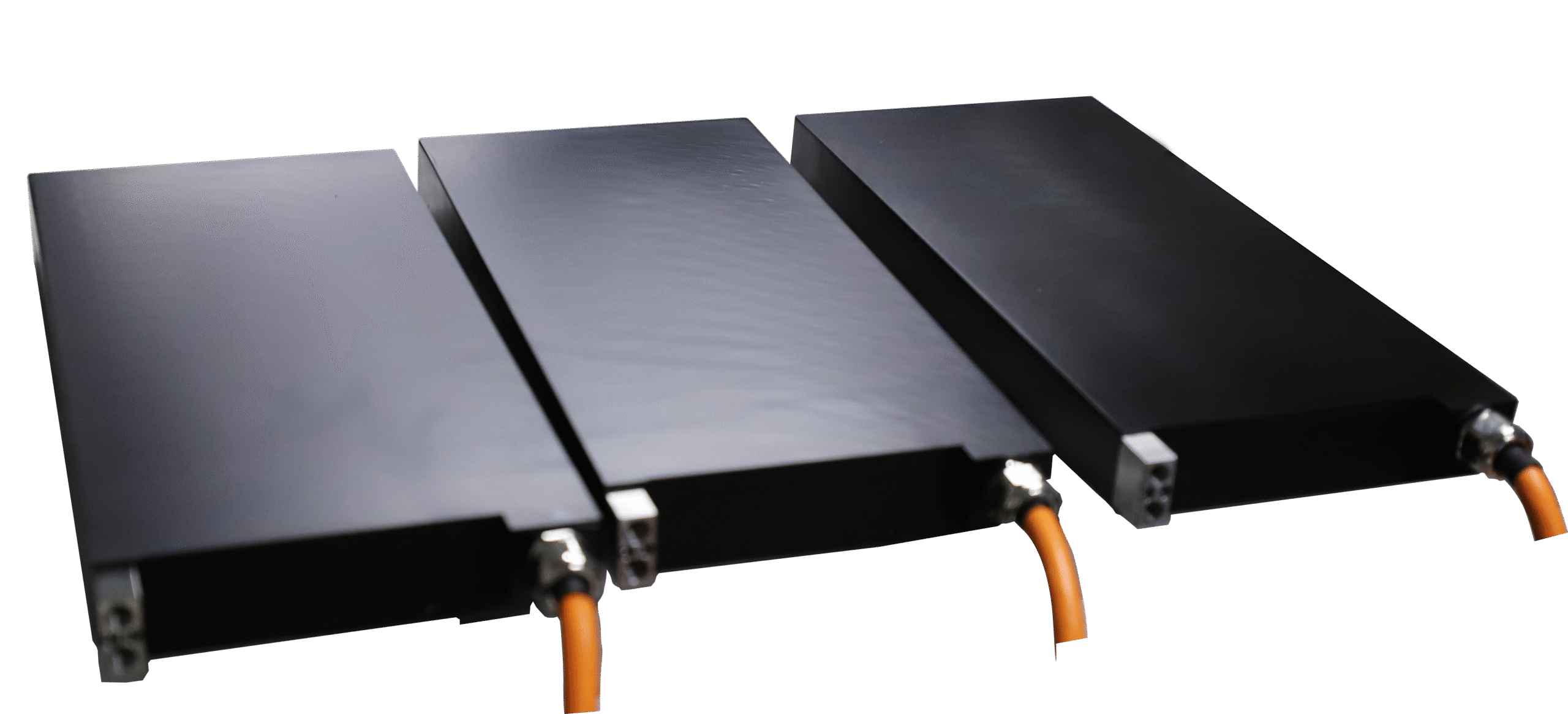

Features

Semiconductor ironless lienar motor is also called carbon fiber board motor with feature high speed, high acceleration, high thrust density and efficient heat dissipation, enabling stable high-performance operation in semiconductor applications.

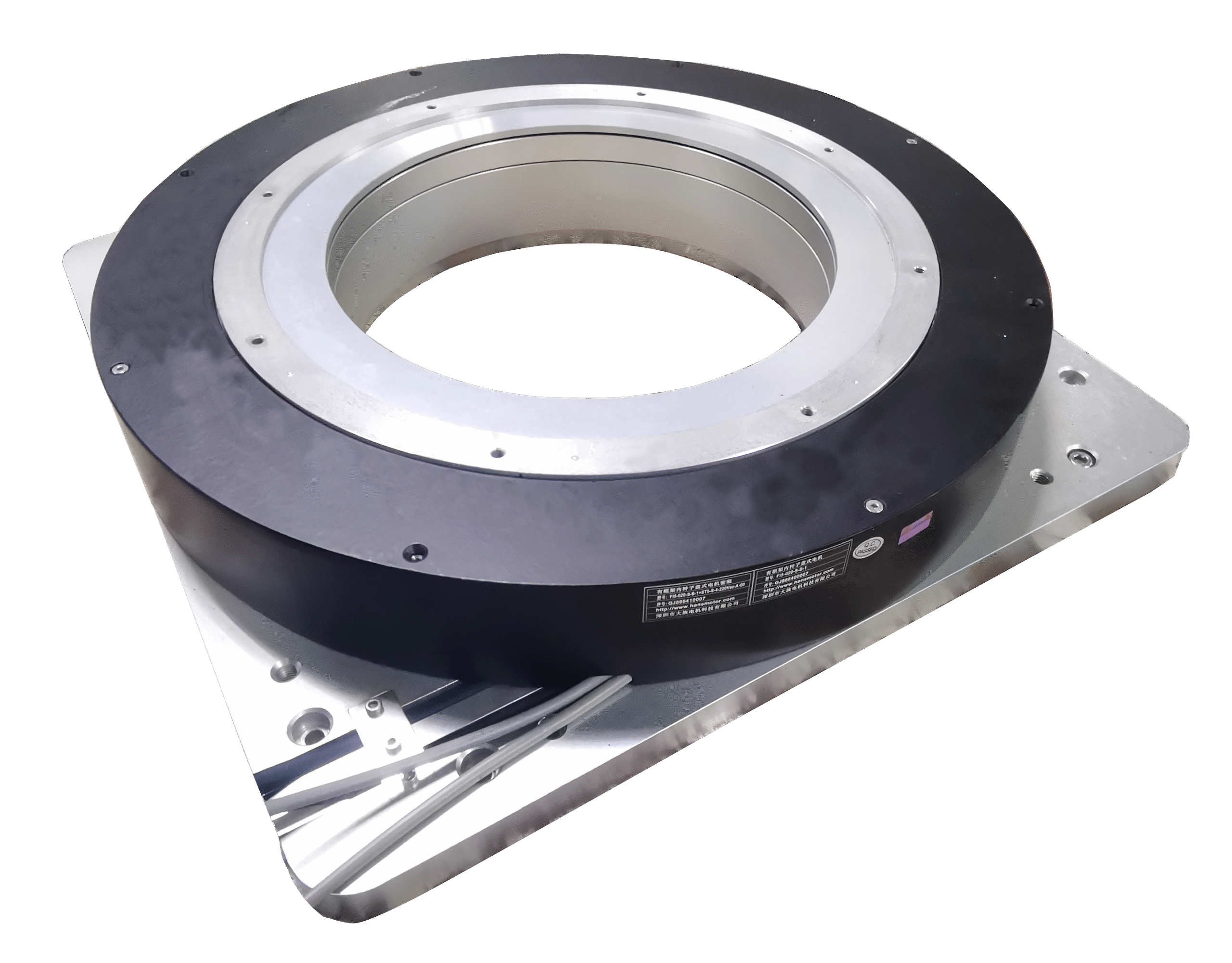

Features

FE3 Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

This linear motor is specially designed for semiconductor packaging equipment, featuring high precision, fast response, and stable performance to meet the demanding requirements of advanced packaging processes.

Features

LSMFK series Water-Cooled Ironcore Linear Motors feature high thrust density 10000Nm and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

LSMD2 series double-sided magnet ironcore linear motor adopt gas cooling technology, high thrust with superior acceleration, cogging torque reduction technology, built-in thermal protection, and cancellation of unbalanced electromagnetic forces in demanding applications.