Products

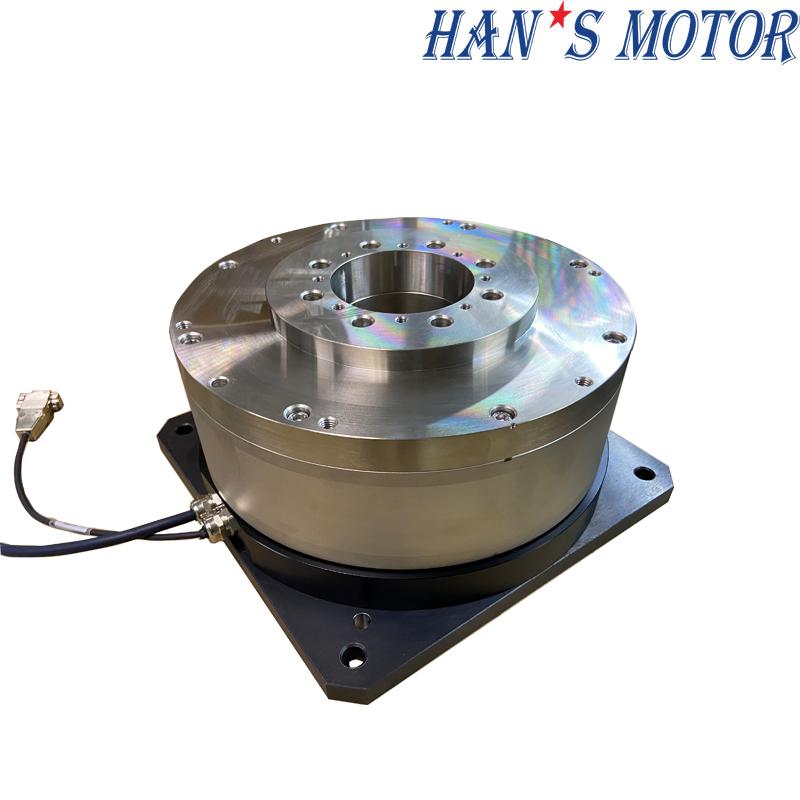

Direct Drive Outer Rotor Torque Motor

The outer rotor direct drive torque motor provides high rotational accuracy with stable output torque, supporting flexible gear integration. Ideal for CNC systems, rotary tables, and automation assemblies requiring consistent speed control and dynamic response.

Brand:

Order(MOQ):

1

Product Detail

Product Specifications

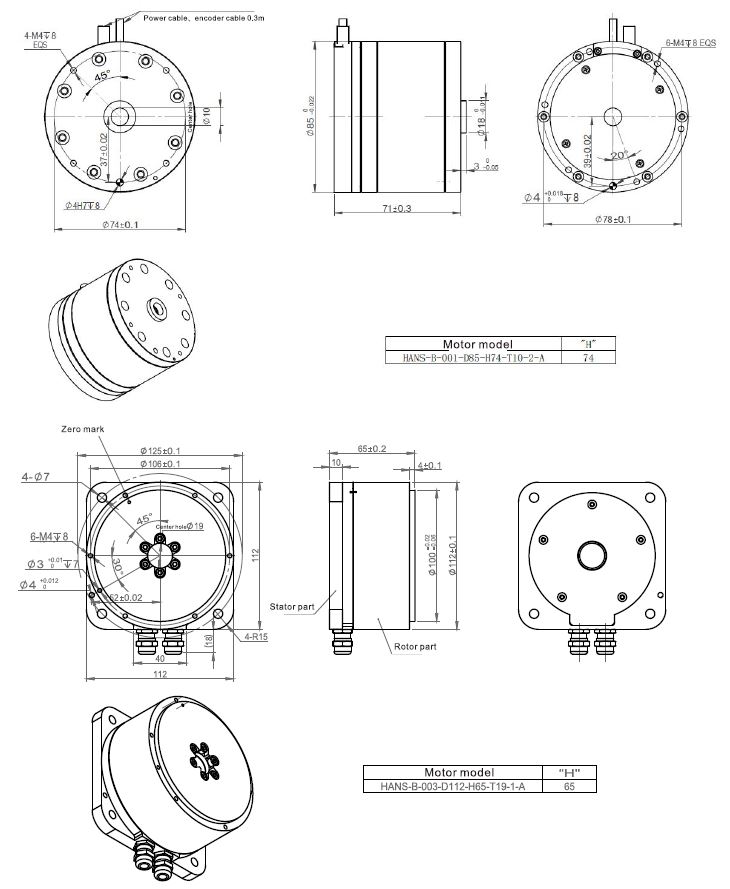

| Frame Outer Rotor Torque Motor HANS-B Series Specification | ||||

| Motor Model No.:HANS-B-xxx-Dxx-Hxx-Txx-x-A | B-001 | B-003 | ||

| Performance Parameters | Symbol | Unit | ||

| Cable Outlet | 1 | 1 | ||

| Outer Diameter | D1 | mm | 85 | 112 |

| Center Hole | D2 | mm | 10 | 19 |

| Installation Height | H | mm | 74 | 65 |

| Continuous torque (Tmax) | Tc | Nm | 1.9 | 3.0 |

| Peak torque | Tp | Nm | 5.5 | 10.0 |

| Vmax,Tc@Vbus=310Vdc | Nmax,Tc | Rpm | 1000 | 700 |

| Vmax,Tp@Vbus=310Vdc | Nmax,Tp | Rpm | 800 | 500 |

| Vmax,0@Vbus=310Vdc | Nmax,0 | Rpm | 1200 | 800 |

| Encoder (BISS-C) | P/rev | 19bits | 19bits | |

| Positioning Accuracy | arc sec | ±10 | ±10 | |

| Repeat Accuracy | arc sec | ±2 | ±2 | |

| Maximum axial load (recommend) | Fa | N | 200 | 200 |

| Maximum torque load (recommend) | T | Nm | 10 | 10 |

| Motor outlet | M | 0.3 | 0.3 | |

| Cable bending radius (within drag chain) | mm | 30 | 30 | |

| Continuous current (Tmax) | Ic | Arms | 1.6 | 1.5 |

| Peak Current (1s) | Ip | Arms | 4.8 | 4.5 |

| Torque Constant (within 25℃±5℃) | Tf | Nm/Arms | 1.18 | 2.00 |

| Electromotive constant (within 25℃±5℃) | Te | Vrms/rad/s | 0.39 | 0.67 |

| Resistance (within 25℃±5℃) | R | Ω(p-p) | 8.3 | 6.1 |

| Inductance (within 25℃±5℃) | L | mH(p-p) | 15.6 | 6.3 |

| Pole pairs | p | 5 | 8 | |

| Max.coil temperature | Tmax | ℃ | 120 | 120 |

| Motor Mass | KG | 2.1 | 3.9 | |

| Mover Mass | Mc | KG | 1.1 | 1.4 |

| Rotor Moment of Inertia | Jm | Kg*m2 | 0.0013 | 0.0027 |

| Axial Runout | mm | 0.03 | 0.03 | |

| Radial Runout | mm | 0.03 | 0.03 | |

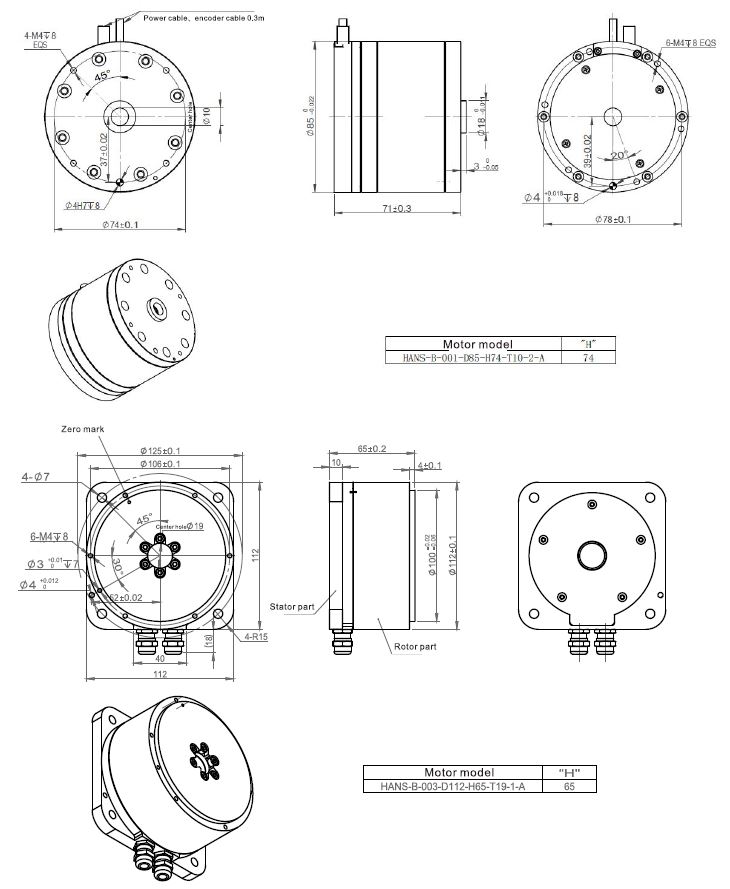

Dimension

Characteristics:

1. Dynamic performance

Dynamic performance is drastically improved by using direct drive due to the very high control loop bandwidth that can be achieved on the overall system. The direct coupling of the load and position feedback to the motor has the advantage of eliminating all phenomena that limit the dynamic performance on non direct driven machines. Eliminating long-time drift, elasticity, and backlash is a huge advantage for machine performance and lifetime.

2. DDR torque motors are controlled much like other brushless motors, but require certain special provisions.

A Direct Drive Motor can be used for various applications, such as applications where a high positioning accuracy is needed. Moreover, these torque motors are used for situations where small size, low weight, maximum power and optimal speed control is desired.

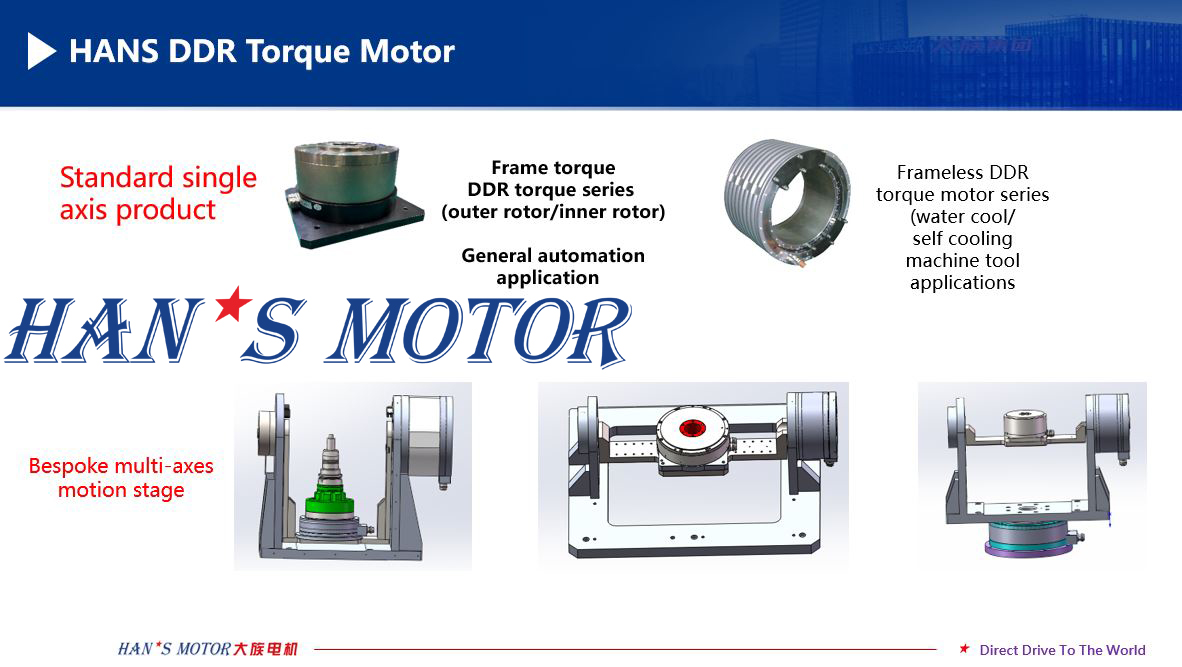

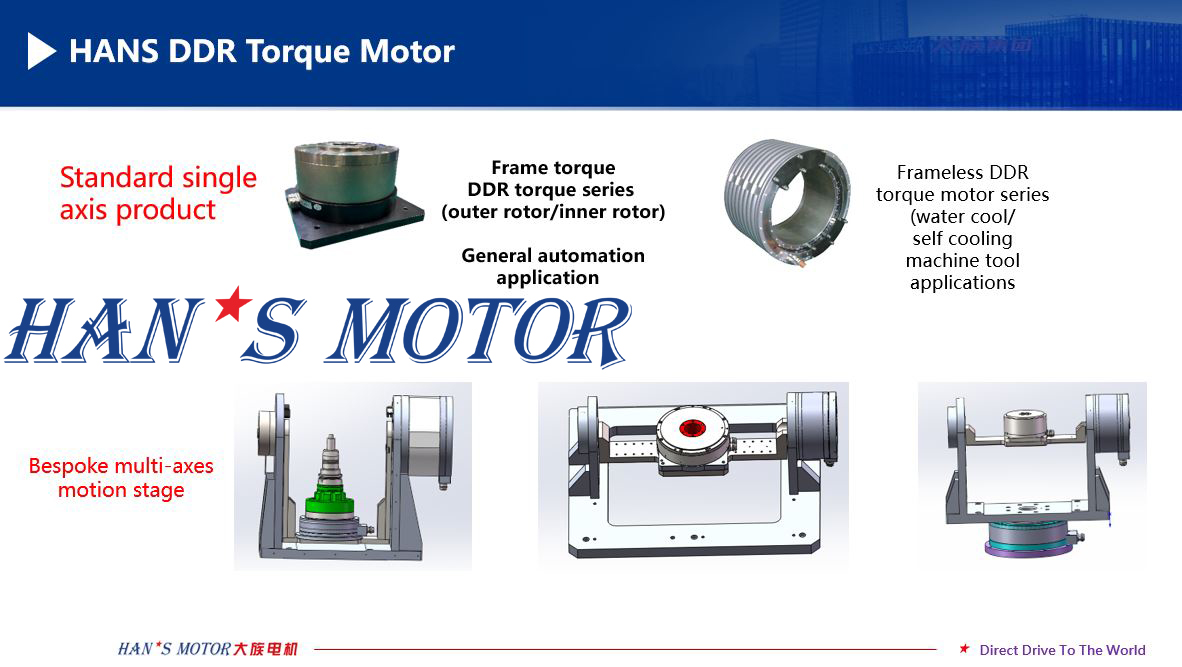

HAN’S MOTOR DDR Torque Motor Products Series.:

Why choose us?

Q1: What is a direct drive motor?

A1: Torque motors are permanent-magnet direct drive motors that rotate along an axis,they can be used wherever a rotary movement is required and offer numerous advantages over conventional servo drives.

Q2: Guarantee time of HAN’S Motor?

A2: One particular year warranty for products and technical support in accordance to your needs.

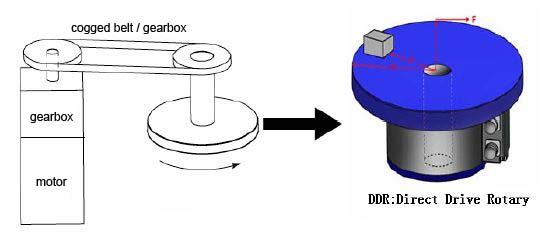

Q3: What’s direct drive?

A3: Direct drive:The load and the motor are directly coupled, without intermediate transmission link, direct drive Including:direct drive linear(DDL)and direct drive rotation(DDR)

Q4: What’s your quality standard?

Passed ISO 9001and ISO 14001 management system certification and CE certificate.

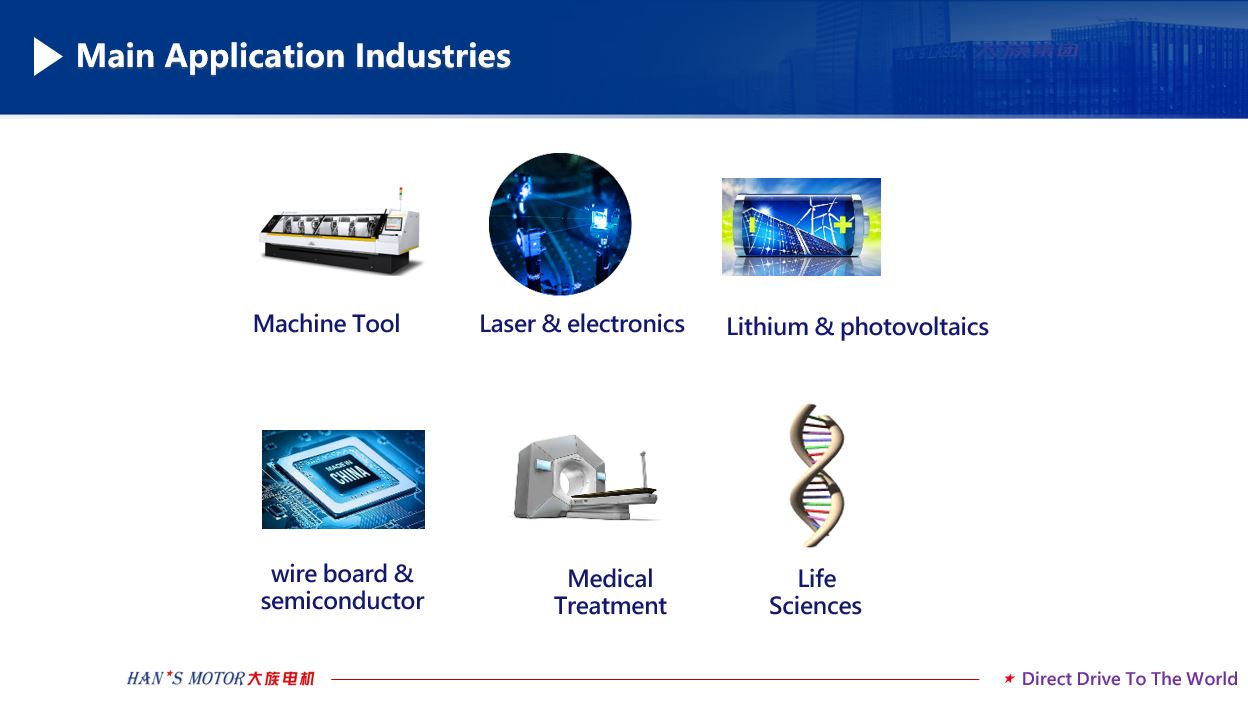

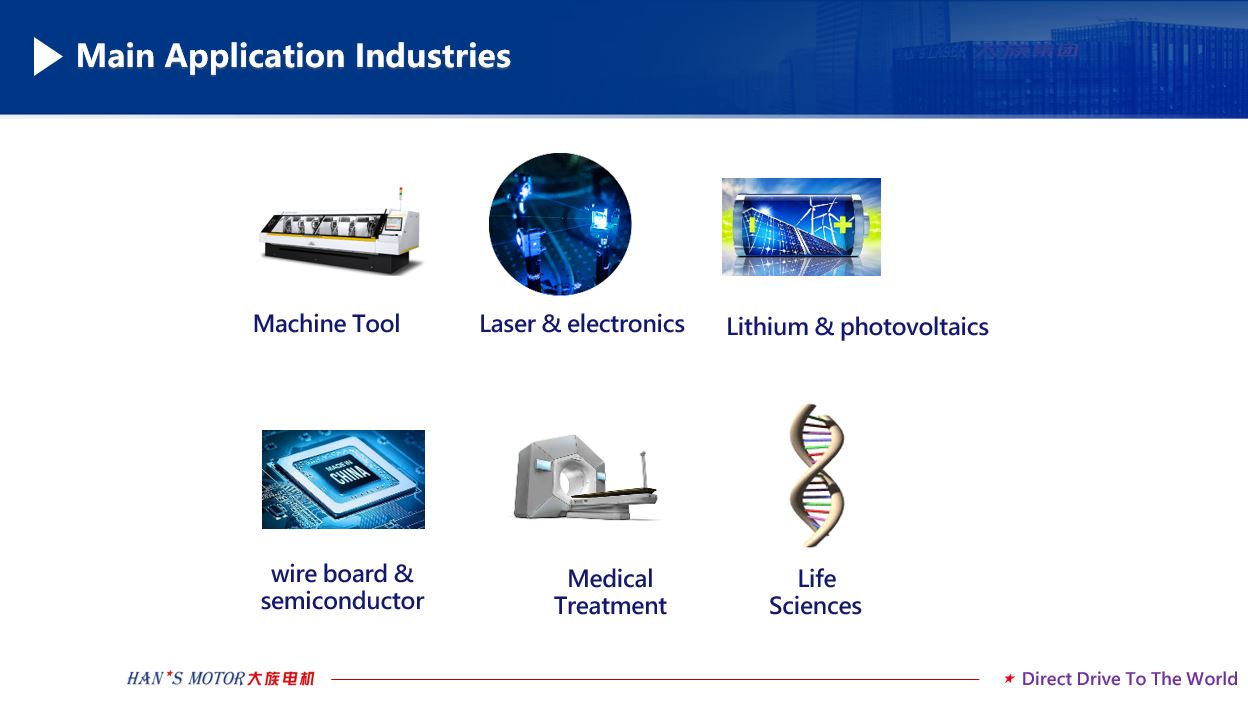

Applications:

Torque motors are used in a wide variety of products, from rotary tables to robotic arms.

CNC high speed machining center, automatic CNC cutting machine, precision CNC grinder,

precision milling machine, marking machine, die bonding machine, engraving machine and printing machine etc.

Exhibitions & International market

Packaging & Delivery:

Packaging Details.: plywood packing

Port.: Shenzhen ( Sea / Air shipping, TNT, UPS, FedEx and DHL ect.)

Leading time: According to the order quantity, 10 days for the small order and 20 days for the bulk order

Sample

Contact Us

Experience our expert support, tailored solutions, and reliable global delivery.

Related Products

Features

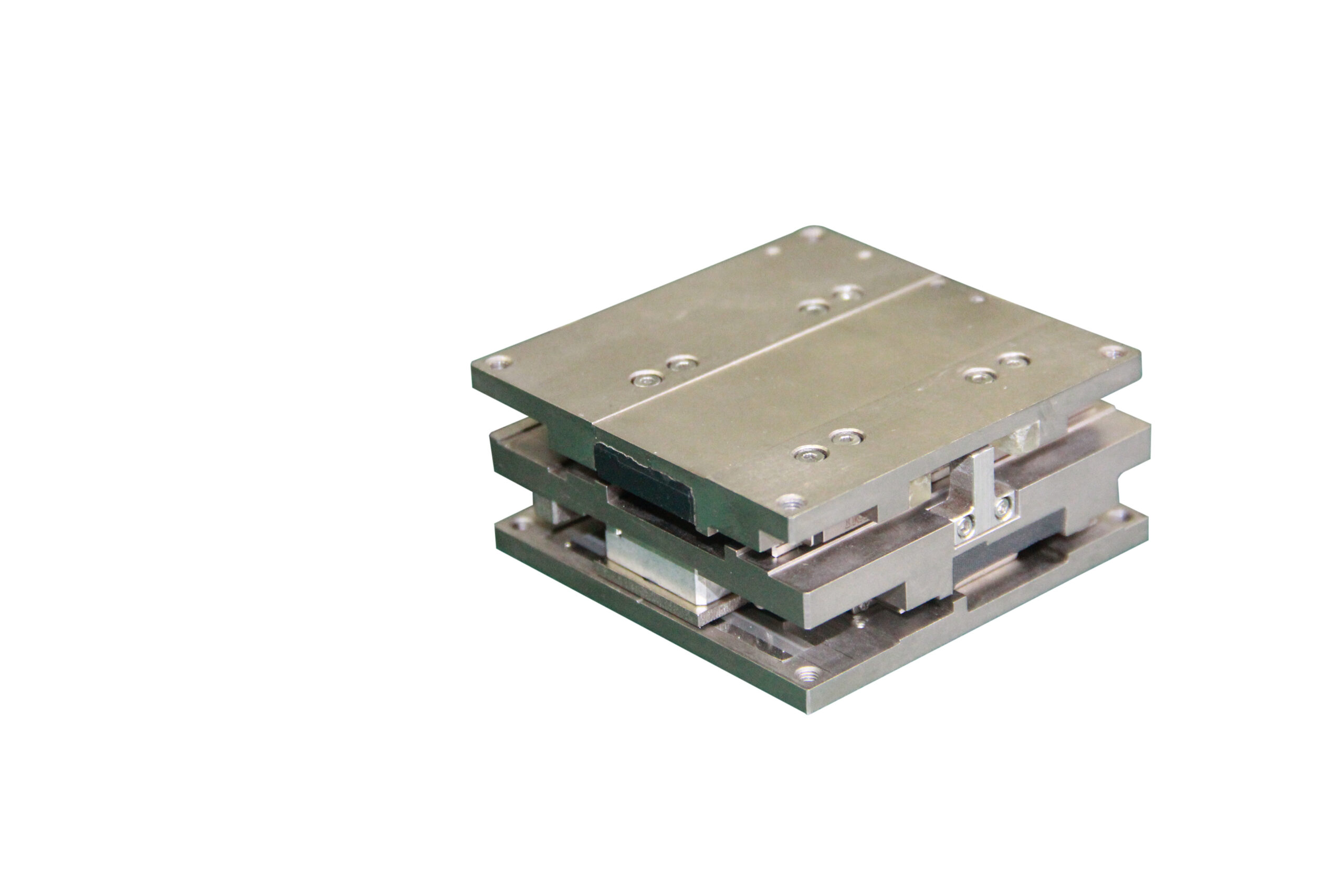

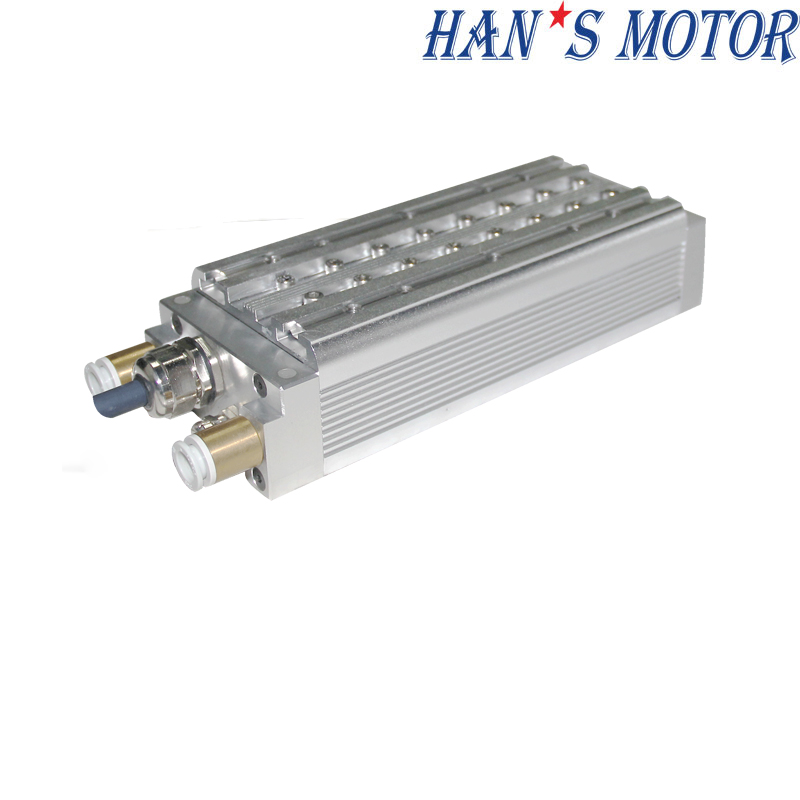

Semiconductor ironless lienar motor is also called carbon fiber board motor with feature high speed, high acceleration, high thrust density and efficient heat dissipation, enabling stable high-performance operation in semiconductor applications.

Features

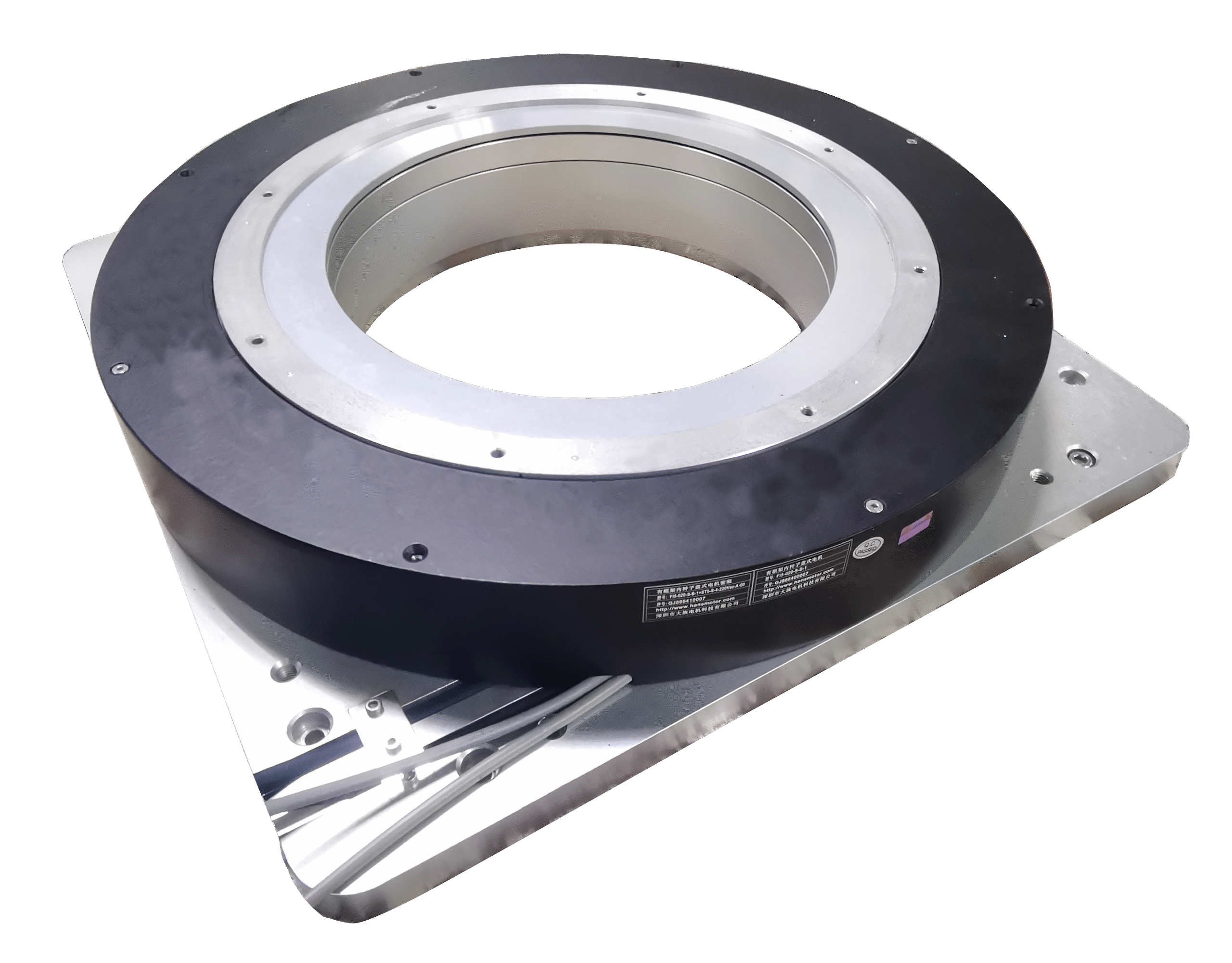

FE3 Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

FI Series Torque motors are designed with industrial-grade quality, optimized for mass production and robust operation in demanding environments. Featuring high torque density, direct-drive architecture, and low maintenance, these motors deliver reliable, precise, and stable performance for industrial automation, robotics, machine tools, and semiconductor equipment. The design supports continuous operation under high load, making it ideal for large-scale industrial applications.

Features

This linear motor is specially designed for semiconductor packaging equipment, featuring high precision, fast response, and stable performance to meet the demanding requirements of advanced packaging processes.

Features

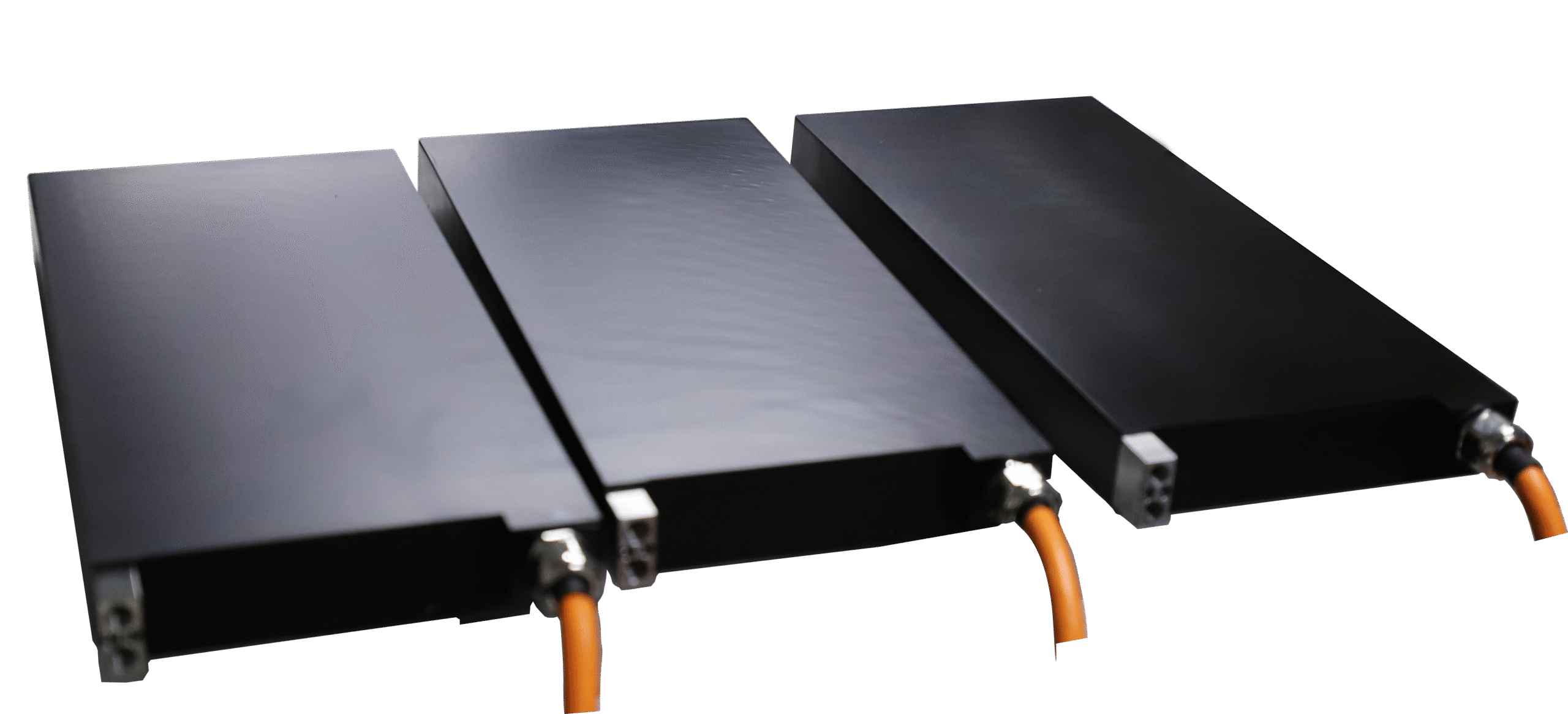

LSMFK series Water-Cooled Ironcore Linear Motors feature high thrust density 10000Nm and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

Water-Cooled Ironcore Linear Motors feature high thrust density and efficient heat dissipation, enabling stable high-performance operation in demanding applications.

Features

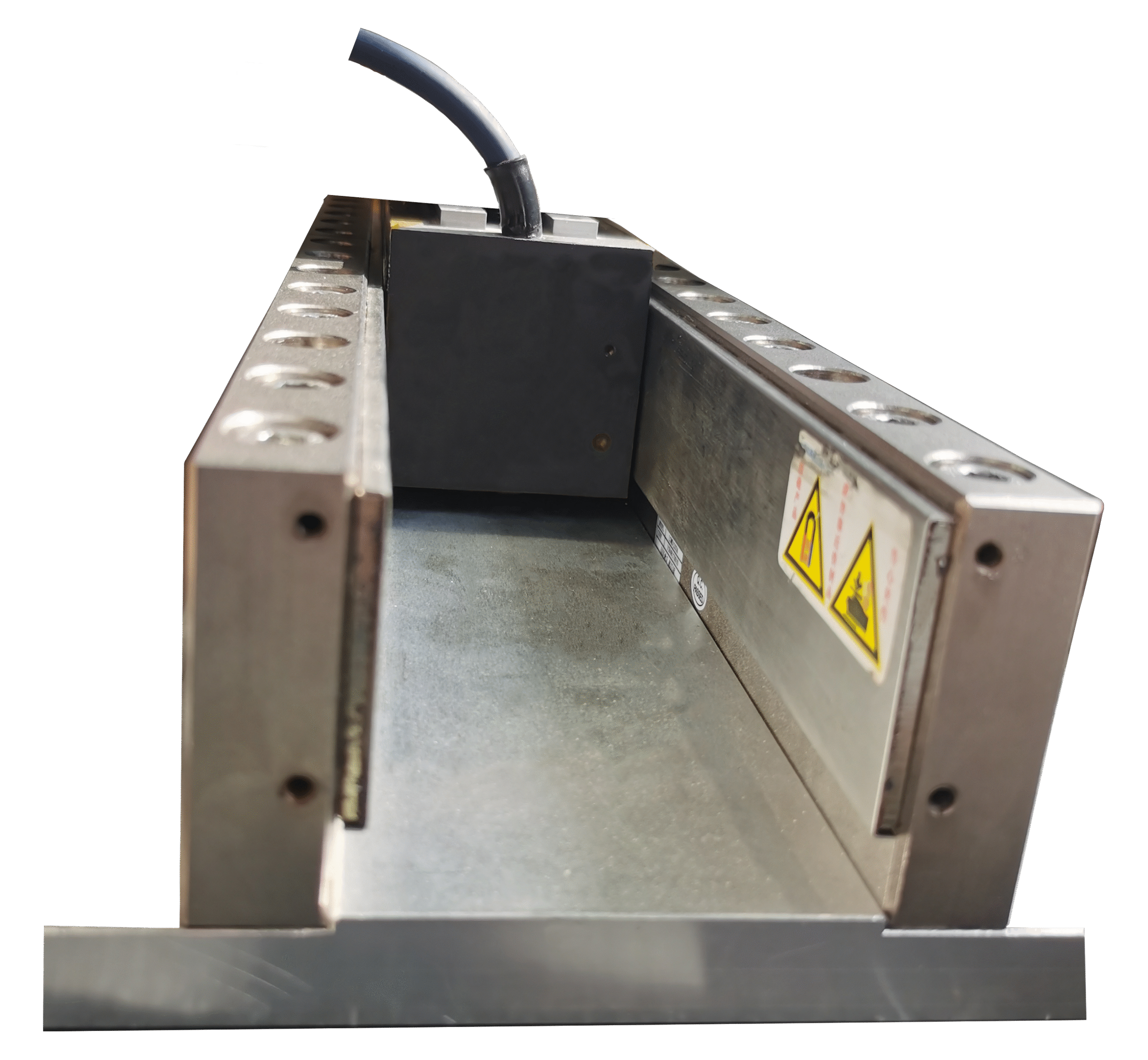

LSMD2 series double-sided magnet ironcore linear motor adopt gas cooling technology, high thrust with superior acceleration, cogging torque reduction technology, built-in thermal protection, and cancellation of unbalanced electromagnetic forces in demanding applications.