Applications

Semiconductor

Han’s Motor linear motors deliver unmatched precision and speed in semiconductor die bonding equipment, ensuring ultra-stable motion control for critical production processes. Trusted by leading companies such as Huawei, HiSilicon Optoelectronics, and Xinkailai, our solutions meet the stringent demands of chip packaging, mini LED bonding, and high-speed IC placement. With sub-millimeter accuracy and cycle times as low as 3ms, we enable manufacturers to boost throughput by over 30% while maintaining exceptional quality consistency. This combination of performance and reliability makes our technology the preferred choice for next-generation semiconductor production lines.

Product Series

Our 2D Aluminum-Base Linear Motor Stages are engineered specifically for semiconductor die bonding, SMT assembly, and precision inspection applications. The integrated aluminum base design delivers high structural rigidity while keeping the platform lightweight for rapid motion response. Combined with modular configuration options, these stages offer versatile adaptability to different equipment layouts without compromising precision. They are ideal for high-density production lines where space efficiency and motion accuracy are equally critical.

Available Models

The LMA38, LMA55, and LMA80 Series provide a versatile range of solutions tailored to different payload, speed, and precision requirements in semiconductor manufacturing. Each model features high-speed acceleration up to 15 m/s² and smooth, backlash-free operation for superior motion stability. Whether for compact bonding heads or large-format inspection systems, these models deliver consistent performance under the most demanding production conditions. Built with long-term reliability in mind, they ensure minimal downtime and optimal ROI for our customers.

Semiconductor-Specific Linear Motors

Han’s Motor develops semiconductor-grade linear motors optimized for die bonders, wire bonders, and wafer inspection systems, offering a seamless balance of speed, accuracy, and durability. With no-load speeds reaching 2 m/s and precision travel control, these motors are capable of meeting or exceeding the highest industry benchmarks. Their superior thermal management and robust mechanical design guarantee consistent performance even in cleanroom and high-duty-cycle environments. By integrating our motion solutions, semiconductor manufacturers gain a significant competitive advantage in both productivity and product quality.

Key Advantages

1.Ultra-Simplified, High-Rigidity Structure:

Integrated aluminum base platform with modular design

2.Ultra-Compact, High-Precision Motion:

Sub-millimeter travel control with zero backlash

3.Semiconductor-Grade High-Speed Response:

Acceleration up to 15 m/s², no-load speed of 2 m/s

Increases UPH (Units Per Hour) by over 30%

Supports bonding cycles ≤3ms, offering up to 40% speed improvement over conventional servo motor systems

Representative Application Cases

- Huawei 5G Chip Packaging Die Bonders

- HiSilicon Optoelectronics Mini LED Die Bonding Equipment

- Xinkailai High-Speed IC Placement Machines

Display Panel Industry

Innovative Applications of Han’s Motor Linear Motors in the Display Panel Sector— Delivering high-precision motion solutions for OLED/LCD inspection, laser patterning, and precision lamination.

Representative Products

LSMU4 and LSMU5 Series Coreless Linear Motors

Key Product Advantages:

- Ultra-high precision positioning

- Stable control over long travel distances

- Compatibility with Class 100 cleanroom environments

- Flexible system scalability

Typical Application Scenarios:

- OLED evaporation mask inspection systems

- Flexible display laser cutting equipment

Robotics

Frameless torque motors, coreless DC motors, and integrated joint modules—providing high-precision motion control for humanoid robots, collaborative robots, and precision robotic joints.

Frameless Torque Motors

Direct-drive torque motors offering high positioning accuracy and high torque output. Commonly used in humanoid robots and various collaborative robot joints, enabling fast response and precise positioning.

Coreless DC Motors

With high power density, rapid response, and excellent controllability in terms of degrees of freedom and precision, these motors are widely applied to various humanoid robot joints, including end effectors and multi-finger joint actuation.

Joint Modules

Specialized drive assemblies designed for robotic joint motion, integrating motor, reducer, sensor, and controller. These modules deliver high torque density, high accuracy, and dynamic responsiveness, effectively replicating the flexibility of human joints.

Encoders

Compact Modular Slot-Type Angular Encoders. Both rotor and stator feature a hollow, flat structure manufactured using mature PCB processes.

1.Key Features:

Simple structure, oil contamination resistance, shock and vibration tolerance, and easy installation.

2.Ideal Applications:

Robotic joint arms, compact direct-drive motors (DD motors), and electro-optical pods.

Dual Encoders

Featuring a unidirectional dual-end design, the rotor and stator adopt a hollow, flat structure, built with reliable PCB technology or integrated metal bases.

1.Key Features:

Building upon the advantages of slot-type encoding technology, the encoder supports fully customizable dimensions to accommodate specific customer structural requirements. The dual encoder allows for both co-directional and counter-directional configurations, enabling simultaneous high-speed output and low-speed feedback within a single unit. It can also be integrated with the control board to achieve combined measurement and control functionality, significantly reducing space consumption.

2.Application Scenarios:

Robotic joints, electric propellers, and gear reducers

3.Typical Applications:

Huawei AI Robotics Project

Robotic End Effectors

Medical Equipment

Han’s Motor provides high-precision and highly reliable drive technologies for the medical industry through its large-aperture frameless torque motors, linear motors, and arc motors.

Key Product Advantages

Our product delivers high precision and reliability while offering maintenance-free operation and low noise. The system’s exceptional accuracy is further enhanced by dual encoder verification, and its design ensures cleanroom compatibility for use in sensitive environments. This comprehensive suite of features is engineered to significantly boost productivity and reduce long-term operational costs, making it the ideal choice for mission-critical applications where performance and durability are paramount.

Representative Products:

- Large-aperture frameless torque motors

- Medical-grade linear motors

- Arc motors

- Voice coil motors

Typical Application Scenario:

Varian Medical Systems – Oncology treatment equipment

PCB Industry

HAN’S Motors’ linear motors provide full-process drive solutions for the PCB industry — covering core equipment such as drilling, exposure, inspection, placement, and depaneling.

Product Advantages:

Han’s Motor linear motors deliver micron-level precision and high-speed performance for PCB drilling, exposure, inspection, and placement, significantly boosting throughput and yield. Built with corrosion-resistant materials and compatible with cleanroom and vacuum environments, they ensure long-term reliability in demanding production conditions. Advanced vibration suppression technology further enhances product quality by minimizing defects during high-speed motion.

Typical Product Series:

LSMF6, LSMU5

Typical Application Scenarios:

- Foxconn High-Speed SMT Placement Machines

Han’s Motor linear motors drive Foxconn’s SMT placement machines with ultra-fast and precise positioning. Their high dynamic response and zero-backlash design ensure accuracy at extreme speeds, boosting UPH and production reliability. - Shengyi Technology PCB Laser Drilling Machines

For Shengyi’s PCB drilling systems, Han’s linear motors provide stable, vibration-free motion for micron-level hole accuracy. Their corrosion-resistant and vacuum-compatible design ensures lasting reliability in cleanroom environments. - Han’s Laser High-Precision LDI Exposure Machines

In Han’s LDI exposure systems, linear motors enable rapid, precise scanning for fine-line PCB manufacturing. Smooth trajectory control delivers superior resolution and alignment, supporting advanced electronics applications.

Laser Equipment Industry

Han’s Motor high-precision motion platforms deliver reliable and accurate motion control systems for laser processing, laser cutting, and engraving applications.

Representative Products:

- Dual-drive linear motor platforms specialized for laser cutting

- Four-axis linear motor motion platforms

- LSMFJ and LSMFL series flat linear motors

Technical Highlights:

- Ultra-precision dual-drive systems

- Military-grade protection design

- Intelligent temperature compensation

Typical Application Scenarios:

- CATL laser cutting machines

- Lead Intelligent bipolar plate laser cutters for fuel cells

- Han’s Laser 5G ceramic filter cutting systems

Precision Machine Tools Industry

HAN’S Motor’s water-cooled linear and torque motors enhance CNC machine tool upgrades by delivering high thrust, torque, and motion precision. Their superior heat dissipation ensures stable performance under heavy loads, while improving cutting accuracy and production efficiency.

Core Product Advantages

1.Water-cooled Linear Motors (LSMF Series):

Thrust density increased by 30%, continuous thrust up to 3000 N (LSMF9 model)

Water-cooling system limits temperature rise to ΔT < 2 ℃, ensuring ±1 μm/m thermal stability

2.Water-cooled Torque Motors (BI Series):

Peak torque 500 Nm (BI-450 model), direct drive replaces worm gear systems

Zero-backlash transmission, angular resolution 0.001°, suitable for five-axis precision indexing

Typical Application Scenarios:

HANS Laser high-precision drilling machines, high-precision gear grinding solutions, high-speed gantry five-axis machining centers

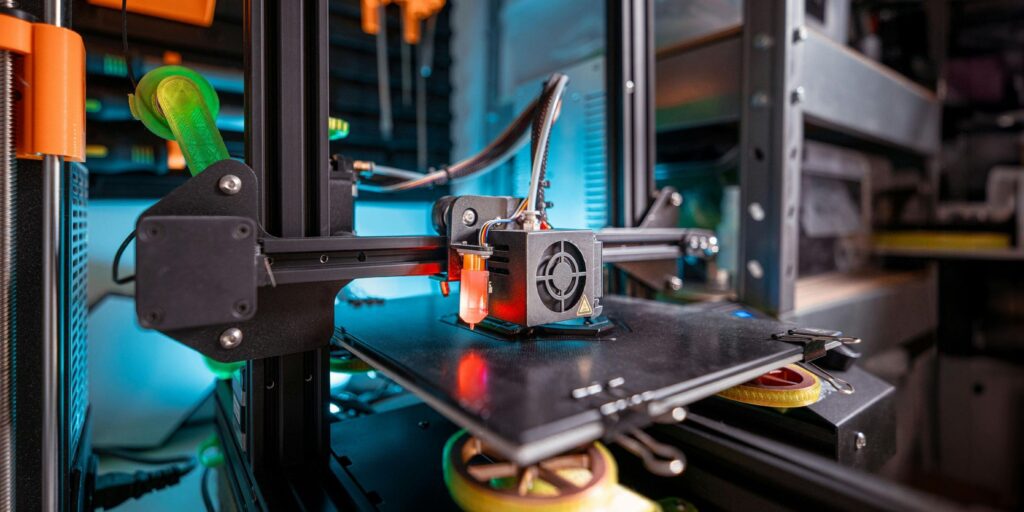

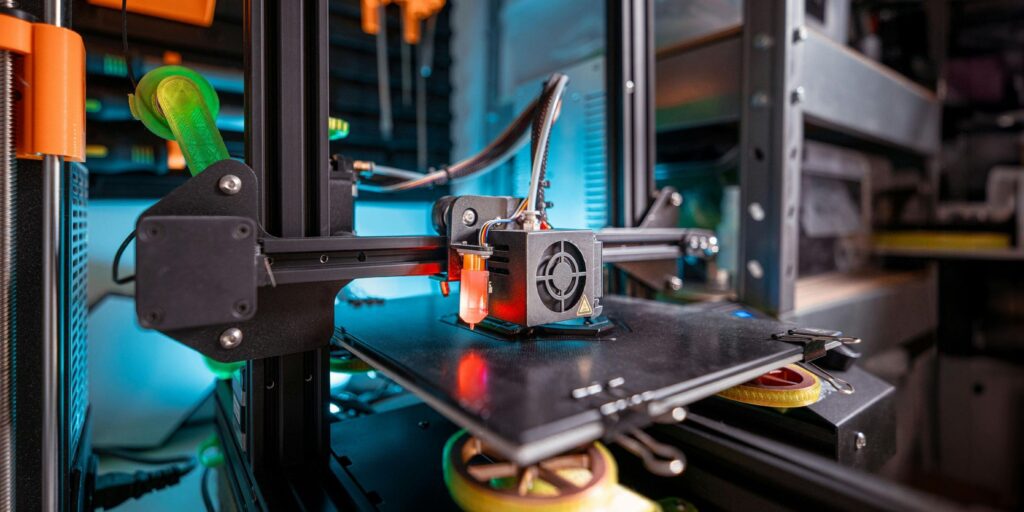

3D Printing

Our coreless and ironless linear motors deliver the fine, precise motion control essential for high-resolution additive manufacturing. With zero cogging and compact form factors, these motors enable smoother layer transitions, faster response, and enhanced print accuracy. The integrated direct-drive design eliminates backlash and reduces maintenance, making them ideal for advanced 3D printers requiring high-performance actuation.

Representative Models

The LSMU4, LSMU5, and LSMU6 Series showcase our modular approach to linear motor design—each validated for cleanroom compatibility, high thrust, and dynamic response. These series differ in payload capacity and structural layout, providing scalable solutions for a variety of automation platforms. Manufacturers can select from these proven models to match specific performance needs, whether it’s speed, precision, or thermal management.

Technical Features

This linear motor features a coreless design for exceptionally smooth thrust with zero cogging force. With a peak acceleration exceeding 10g, it delivers instantaneous response and precise positioning. The customizable travel length of up to several meters makes it an ideal solution for a wide range of long-stroke, high-precision applications.

Typical Case

In collaboration with Hefei Lebo Technology, Han’s Motor developed an industrial-grade FDM 3D printer equipped with the LSMU series linear motors. The implementation led to a more than 30% increase in printing efficiency and eliminated traditional travel limitations. Building on past cooperation in equipment development and technological innovation, both parties will further expand the application of linear motor system solutions in 3D printing equipment.

Key Application Scenarios

1.High-Speed Precision Positioning

Designed for high-speed, high-precision applications, the synchronous drive of the multi-nozzle arrays allows for coordinated operation over a working area larger than 500x500mm. A dynamic response time of under 2ms ensures that even the most complex geometric paths are accurately and efficiently reproduced.

2.Intelligent Extrusion System

This system features a directly coupled screw-drive system that achieves thrust fluctuation of less than 1%, providing exceptional stability and consistent performance. It also supports instant start/stop for materials like PLA and ABS, which reduces the filament breakage rate by an impressive 90%.

3.Ultra-Long Travel Solutions

The system’s modular splicing technology enables travel lengths exceeding 10 meters, making it ideal for printing large aerospace components. Despite its expansive scale, it maintains exceptional precision, with a full-stroke positioning error of less than 0.01mm/m. This ensures high accuracy across the entire working area.

3C Electronics Industry

HAN’S Motors’ double-sided secondary linear motors and flat linear motors enable innovative applications in PCB dispensing equipment — delivering high-speed, high-precision, long-life ultimate solutions.

Product Series

LSMD, LSMFJ, LSMFL

Technical Advantages:

Han’s Motor linear motors feature a compact, lightweight design ideal for high-density production lines and equipment miniaturization. They deliver ultra-high-speed performance with micron-level precision, boosting throughput for demanding tasks like dispensing and laser cutting, all while offering low maintenance and a long service life.

Typical Application Scenarios:

Han’s Motor solutions are widely used in advanced Huawei dispensing machines and SMT placement machines, enabling ultra-fast and accurate component assembly. For FPC laser cutting, the motors ensure stable, high-speed motion for clean, precise cuts. These applications highlight the motors’ ability to meet the growing demand for miniaturization and mass production in the 3C electronics sector.

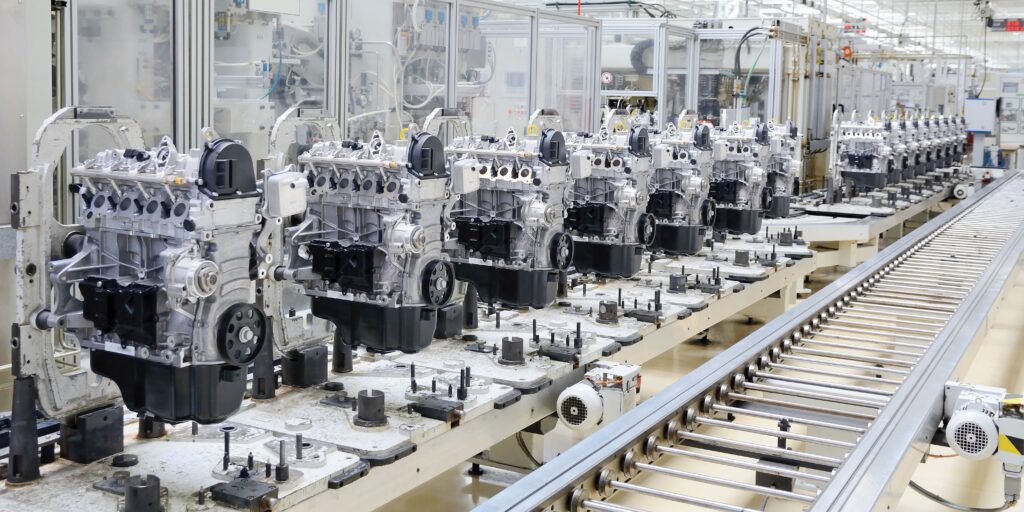

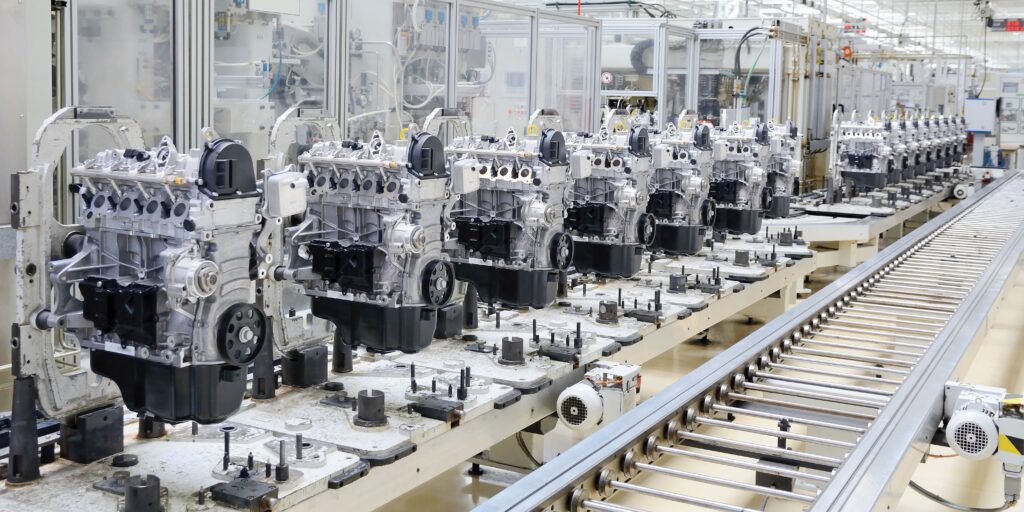

Automation Industry

HAN’S Motors’ linear motors provide full-scenario drive solutions for the automation industry — covering logistics, assembly, inspection, packaging, robotics, and other core fields.

Technical Advantages

- All six-axis joints adopt BI series frameless torque motors with direct drive, integrated with dual encoders to achieve ±0.01° angular control.

- Driven by LSMF6 linear motors, achieving a speed of 4 m/s, acceleration of 5 G, with a dynamic target tracking algorithm, ensuring a misplacement rate <0.001%.

- The main drive uses a BI-150 water-cooled torque motor, replacing cam mechanisms, supporting one-click recipe switching, reducing changeover time from 2 hours to 5 minutes.

Product Series

LSMF6 series linear motors, BI series frameless torque motors

Typical Application Scenarios

Our systems are widely used in CATL’s high-speed lithium battery module sorting lines, where they provide the necessary speed and precision to meet the demands of large-scale production. The technology’s high-speed performance and sub-millimeter accuracy are critical for ensuring efficient throughput, a key requirement in the rapidly expanding battery industry.

Additionally, our solutions are integral to Bosch’s automotive parts assembly robots. The systems deliver reliable and precise assembly in a demanding manufacturing environment, ensuring the accurate placement of delicate components and contributing directly to product quality and manufacturing yield. These applications demonstrate the technology’s versatile ability to meet the rigorous demands for speed, precision, and reliability in both the battery and automotive sectors.